Pin Extruder for Composite Rubber Seal Strips: Your Ultimate Guide to Advanced Sealing Solutions

Pin extruder for composite rubber seal strips represents a significant leap forward in manufacturing technology, offering unparalleled precision and efficiency. When you're in the market for high-performance sealing solutions, understanding this specialized equipment is crucial. It's not just another piece of machinery; it's the core of producing durable, complex seals that meet stringent industry standards.

You might wonder what sets a pin extruder apart from conventional extrusion methods. The answer lies in its unique ability to process composite materials—blending different rubber compounds or integrating reinforcing elements—into a single, cohesive seal strip profile. This capability is essential for applications demanding specific properties like enhanced weather resistance, improved compression set, or superior sealing force.

Choosing the right technology directly impacts your product quality, production costs, and overall competitiveness. This guide will walk you through everything you need to know about pin extruders for composite rubber seal strips, from their fundamental advantages to selecting the perfect system for your operation.

1、Why Choose a Pin Extruder for Composite Seal Strips?

1.1、Unmatched Precision in Profile Control

1.2、Superior Material Homogeneity and Bonding

1.3、Enhanced Production Flexibility and Speed

1.4、Significant Reduction in Material Waste

2、Core Components and How the Pin Extruder Works

2.1、The Precision Screw and Barrel Design

2.2、The Role of the Pin Mixing Section

2.3、Integrated Crosshead and Die Systems

2.4、Smart Control and Monitoring Units

3、Key Applications and Industries Served

3.1、Automotive Weather Seals and Gaskets

3.2、High-Performance Architectural Glazing

3.3、Specialized Industrial and Appliance Seals

3.4、Custom Medical and Electronic Sealing Components

4、Selecting the Right Pin Extruder for Your Needs

4.1、Assessing Your Material and Profile Complexity

4.2、Evaluating Output Capacity and Floor Space

4.3、Prioritizing Energy Efficiency and Automation

4.4、Ensuring Reliable Service and Technical Support

1、Why Choose a Pin Extruder for Composite Seal Strips?

When you consider investing in a pin extruder for composite rubber seal strips, the decision often boils down to achieving superior product performance and manufacturing efficiency. Unlike traditional single-screw extruders, a pin extruder features a unique barrel design with rows of pins that disrupt and homogenize the material flow. This intensive mixing action is crucial when you are processing composite materials—blending different rubber compounds, fillers, or even integrating continuous fibers or metal reinforcements directly into the extrusion profile. The result is a seal strip with exceptionally uniform properties, eliminating weak points and ensuring consistent sealing force, weather resistance, and durability across the entire length.

For a manufacturer like APEX, which specializes in advanced and intelligent industrial solutions, the pin extruder technology aligns perfectly with our mission to deliver precision and innovation. Our expertise in high-precision extrusion for medical and industrial applications directly translates into robust systems for composite seals. By choosing a pin extruder, you gain the capability to produce complex, multi-material seals in a single, streamlined process. This not only enhances your product quality, meeting the stringent demands of automotive, construction, and electronic industries, but also significantly reduces production steps, material waste, and overall operational costs, giving you a distinct competitive edge in the global market.

1.1、Unmatched Precision in Profile Control

You achieve unmatched precision in profile control because a pin extruder precisely manipulates the material flow. Unlike traditional extruders that rely on a single, broad flow channel, the pin extruder features a series of adjustable pins within the die. These pins act as individual flow regulators, allowing you to fine-tune the thickness and distribution of material across the entire cross-section of the emerging seal strip.

This granular control is critical when you are processing composite materials. For instance, if your seal strip requires a soft, spongy sealing bulb integrated with a rigid, structural carrier, the pin extruder lets you independently adjust the flow rates for each compound. You ensure the soft section fills perfectly without over-compressing, while the rigid section maintains its dimensional integrity and strength, all within a single, co-extruded profile.

The result for you is a finished product with exceptional dimensional consistency from start to finish of a production run. You eliminate common defects like variations in wall thickness, sink marks, or incomplete filling of complex geometries. This level of precision directly translates to a seal strip that performs reliably, with consistent compression and sealing force along its entire length.

Ultimately, this precision empowers you to manufacture highly complex, multi-material seal designs that were previously impossible or too costly with standard extrusion. It gives you the capability to innovate and meet the most demanding specifications of your clients in automotive, construction, and appliance industries.

1.2、Superior Material Homogeneity and Bonding

When you process composite rubber materials, achieving a perfect molecular-level bond between different compounds is paramount. A pin extruder excels here by employing a series of strategically placed pins within the barrel. These pins disrupt and reorient the polymer flow, creating intense distributive and dispersive mixing. For you, this means the various rubber components—be it EPDM for weather resistance and a softer compound for sealing force—are blended into a truly homogeneous mass before extrusion.

This superior homogeneity directly translates to the integrity of your final seal strip. You eliminate weak points or delamination risks that can occur with less sophisticated methods like co-extrusion or simple strip lamination. The pin extruder ensures the composite acts as a single, unified material, not just layers stuck together. This is critical for long-term performance under dynamic stress, temperature cycles, and environmental exposure.

Furthermore, the enhanced bonding facilitated by the pin extruder's mixing action improves the physical properties of the seal. You benefit from consistent cross-link density throughout the profile during vulcanization, leading to uniform hardness, tensile strength, and compression set. This consistency is something your customers will rely on for a leak-proof, durable seal in demanding applications like automotive, construction, or industrial machinery.

1.3、Enhanced Production Flexibility and Speed

When you operate a pin extruder for composite rubber seal strips, you gain immediate control over production speed. Unlike traditional single-screw extruders that may struggle with complex material flows, the pin barrel design promotes superior mixing and melting. This allows you to run the extruder at higher screw speeds without sacrificing the homogeneity or quality of the final composite profile. You can meet tight deadlines and respond to fluctuating order volumes much more efficiently.

The flexibility is truly transformative. With a single machine, you can produce a wide range of composite seal strip designs by simply changing the die and adjusting processing parameters. Whether you need to switch between different rubber compound layers, integrate a fabric or metal reinforcement, or alter the strip's cross-sectional geometry, the changeover process is significantly streamlined. This reduces downtime and enables you to offer a broader product portfolio without major capital investment in additional dedicated lines.

This enhanced speed and flexibility directly translate to cost savings and a stronger market position. You minimize material waste through precise control, reduce energy consumption per unit produced due to efficient processing, and unlock the ability to handle smaller, customized batches profitably. Ultimately, this technology empowers you to be both a high-volume supplier and a specialist for niche, high-value sealing solutions.

1.4、Significant Reduction in Material Waste

When you operate a pin extruder for composite rubber seal strips, you directly tackle one of the most persistent cost drivers in extrusion: material waste. Traditional extrusion methods often struggle with the precise control needed for co-extruding multiple materials, leading to off-spec product, start-up scrap, and purging losses. The pin extruder's design inherently minimizes these issues.

The key lies in its superior process stability and control. The internal pins within the barrel create a more homogeneous melt with less temperature variation. This means you achieve a stable, consistent extrusion profile much faster after start-up or a material change. You spend less time and material 'dialing in' the process, dramatically reducing the scrap generated during these transitional phases.

Furthermore, the precision in layer distribution and interface control eliminates the common problem of off-spec seals where material ratios are incorrect or layers are poorly bonded. You produce a higher yield of usable, on-spec product from the same amount of raw material. This efficiency is not just about saving material costs; it also reduces your waste handling and disposal expenses, contributing to a more sustainable and cost-effective manufacturing operation.

Ultimately, the significant reduction in material waste provided by a pin extruder translates directly to improved profitability. You maximize the value of your raw material investment, enhancing your competitive edge in markets where cost control and efficiency are paramount.

2、Core Components and How the Pin Extruder Works

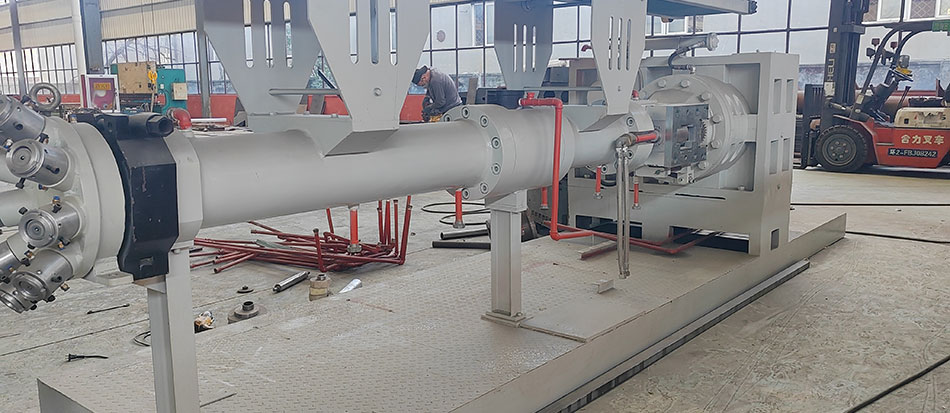

To truly appreciate the precision of a pin extruder for composite rubber seal strips, you need to understand its core components and operation. At its heart, the system integrates a specialized screw and barrel assembly designed for gentle yet thorough mixing of multiple rubber compounds. The defining feature is the 'pin' section—a series of strategically placed pins protruding into the barrel that disrupt the material flow, creating intensive distributive mixing without excessive shear heat. This is crucial for maintaining the integrity of composite materials. The melt then flows through a precisely engineered die head, which shapes the homogeneous blend into your desired complex seal profile with exceptional dimensional stability.

As a leader like APEX (Qingdao Aipake Machinery Technology Co., Ltd.) would engineer, modern pin extruders incorporate advanced temperature control zones and intelligent drive systems. This ensures consistent processing of sensitive formulations, whether for automotive weather-stripping or high-specification industrial seals. The intelligent integration of these components allows you to produce composite seal strips with layered properties—like a soft sealing lip bonded to a rigid carrier—in a single, continuous, and efficient process, directly translating to higher product performance and manufacturing economy for your operations.

2.1、The Precision Screw and Barrel Design

At the heart of the pin extruder's superior performance lies its precision screw and barrel design. Unlike a standard single-screw extruder, this system features a screw with a series of precisely machined pins or mixing elements protruding from the barrel wall into the screw channel. This intricate geometry is what enables the thorough and controlled processing of your composite rubber compounds.

As the rubber material is conveyed forward by the screw rotation, these pins repeatedly interrupt the flow, creating multiple divisions, reorientations, and recombinations of the material stream. For you, this means an exceptionally homogeneous blend of different polymer phases, fillers, oils, and additives. It ensures that the reinforcing elements or the distinct rubber layers in your composite seal strip are perfectly integrated, eliminating weak points or inconsistencies in the final profile.

The barrel sections housing these pins are also specially designed with corresponding grooves or channels. This design works in concert with the screw to apply precise shear and elongational forces to the compound. You achieve optimal dispersion of ingredients without generating excessive heat that could scorch the rubber, preserving the vital physical properties of your sealing material.

Ultimately, this precision engineering directly translates to the quality of your extrudate. You get a composite rubber strip with uniform cross-section, consistent density, and predictable vulcanization behavior. This reliability in the extrusion process is fundamental to producing seals that perform consistently under pressure, temperature extremes, and long-term environmental exposure.

2.2、The Role of the Pin Mixing Section

The pin mixing section is the heart of your pin extruder, where the true magic of composite material processing happens. Unlike a standard screw that relies primarily on shear, this section features a series of precisely engineered pins protruding radially from the barrel into the screw channels. As the rubber compound passes through, these pins repeatedly split, reorient, and recombine the material flow.

This action creates an intensive, yet controlled, distributive mixing effect. For you, this means achieving a perfectly homogeneous blend of different rubber polymers, fillers, oils, and curatives. It ensures that reinforcing elements or a secondary compound are uniformly distributed throughout the primary matrix, eliminating streaks or weak spots in your final seal strip profile.

The design of the pin section allows for excellent temperature control. The mechanical working generates heat, but the increased surface area and interrupted flow promote efficient heat transfer to the barrel's cooling zones. This prevents thermal degradation of sensitive compounds, giving you consistent viscosity and processing stability critical for tight-tolerance extrusion.

Ultimately, the role of the pin mixing section is to deliver a fully homogenized, thermally uniform melt to the die head. It is this foundational quality that enables your pin extruder to produce composite rubber seal strips with reliable, repeatable properties—be it specific hardness, gas permeability, or adhesion to a core substrate—meeting the most demanding application specifications.

2.3、Integrated Crosshead and Die Systems

At the heart of the pin extruder's capability for composite profiles lies the integrated crosshead and die system. This is where the separate material streams, guided by the internal pins, converge and are precisely shaped into your final seal strip. Think of it as the final, critical molding station where the composite structure is locked in place before curing.

You need a crosshead designed for laminar, non-turbulent flow to prevent material intermixing where it's not desired. The die, mounted directly onto the crosshead, defines the exact external geometry of your seal. For composite strips, the die design is paramount in ensuring that different material layers maintain their intended position and thickness throughout the profile's cross-section.

The integration between the crosshead and die is engineered for thermal uniformity and minimal pressure drop. This stability is non-negotiable for you, as it directly affects dimensional consistency, surface finish, and the integrity of the bond between the different rubber compounds in the composite structure.

Ultimately, this subsystem transforms the controlled, multi-channel extrusion process into a tangible product. A well-designed integrated crosshead and die system is what allows you to reliably produce complex, co-extruded seal strips with features like a soft sealing bulb fused to a rigid carrier in a single, continuous, and efficient operation.

2.4、Smart Control and Monitoring Units

Smart control and monitoring units are the brain of your pin extruder for composite rubber seal strips. They translate complex production requirements into precise, repeatable machine actions. You rely on these systems to maintain consistent material flow, temperature profiles, and pin positioning, which are critical for achieving a homogeneous composite structure and perfect dimensional accuracy in every meter of extruded seal.

At the heart of these units, you'll typically find a Programmable Logic Controller (PLC) integrated with a Human-Machine Interface (HMI). This setup allows you to input and store recipes for different seal strip profiles. With a few touches on the screen, you can recall settings for material feed rates, barrel and die temperatures, screw speed, and the synchronized movement of the internal pins, ensuring a swift and error-free changeover between production runs.

Real-time monitoring is where the "smart" functionality truly shines for you. Sensors placed along the barrel, at the die, and on the pins continuously feed data back to the control unit. You can monitor melt pressure and temperature in real-time, receiving instant alerts if any parameter deviates from the set tolerance. This proactive approach prevents defects like material degradation, inconsistent cross-sections, or poor layer bonding before they result in costly scrap.

Furthermore, advanced systems offer data logging and connectivity features. This means you can track production efficiency, analyze historical performance data, and even integrate the extruder into a broader Industry 4.0 network for centralized production management. For you, this translates into actionable insights for predictive maintenance, quality traceability, and continuous process optimization, ultimately driving down operational costs and boosting product reliability.

3、Key Applications and Industries Served

When you invest in a pin extruder for composite rubber seal strips from APEX, you're unlocking capabilities that serve critical applications across diverse industries. In the automotive sector, your production lines can create multi-material seals for doors, windows, and trunks that offer superior noise, vibration, and harshness (NVH) performance alongside long-term weather resistance. For the construction industry, you can produce complex composite gaskets and profiles for windows, curtain walls, and expansion joints, ensuring energy efficiency and durability against environmental extremes. In electronics and appliances, your equipment enables the manufacture of precise, conductive, or shielding seals that protect sensitive components. APEX's technology, proven with over a thousand leading global clients, empowers your business to meet the exacting standards of these high-value markets, enhancing your product portfolio and competitive edge worldwide.

3.1、Automotive Weather Seals and Gaskets

In the automotive sector, you rely on pin extruders to produce high-integrity weather seals and gaskets. These components are critical for sealing doors, windows, sunroofs, and trunks against water, dust, wind noise, and temperature extremes. The pin extruder's ability to co-extrude multiple rubber compounds or integrate a dense sponge core with a solid skin in a single pass is a game-changer for your production line.

You achieve profiles with complex geometries and varying hardness zones using this technology. For instance, the seal's bulb section that provides the compression can be made from a softer, more resilient compound, while the mounting lip or carrier section is extruded from a harder, more rigid material. This composite structure, manufactured seamlessly, ensures optimal sealing performance and long-term durability under constant compression and UV exposure.

The precision control of a pin extruder directly translates to consistent part dimensions and material distribution. For you, this means every meter of seal strip meets tight automotive OEM specifications, eliminating leaks and reducing warranty claims. It also allows for the integration of functional elements, such as a conductive strip for electrostatic discharge or a flocking channel, directly into the extruded profile.

Ultimately, by utilizing pin extrusion technology, you can manufacture lightweight yet robust sealing systems that contribute to vehicle cabin comfort, acoustic performance, and overall quality. This capability is essential for staying competitive in an industry where sealing reliability is non-negotiable.

3.2、High-Performance Architectural Glazing

In high-performance architectural glazing, your primary challenge is to create a seamless, durable, and energy-efficient barrier against the elements. The composite rubber seal strips produced by a pin extruder are engineered precisely for this critical role. They are not just simple gaskets; they are complex, multi-material profiles that provide long-term weather sealing, structural support, and thermal insulation for curtain walls, windows, and structural glass facades.

You need seal strips that can withstand decades of UV exposure, extreme temperature cycling, and constant mechanical stress without degrading. The pin extruder's capability to co-extrude different elastomers—such as combining a soft, sealing EPDM with a rigid, load-bearing TPV—allows you to design a single profile with multiple functionalities. This integrated construction ensures a perfect balance between compression force for sealing and structural integrity for holding the glass in place.

Furthermore, the precision of the pin extruder guarantees consistent profile geometry and material distribution. For you, this translates to reliable installation performance, uniform compression across the entire glazing system, and elimination of weak points that could lead to air or water infiltration. The result is a building envelope that meets the highest standards for air tightness and water penetration resistance, directly contributing to energy savings and occupant comfort.

When specifying seal strips for demanding architectural projects, the choice of manufacturing technology is paramount. By utilizing pin extruder-produced composite seals, you equip your glazing systems with components that offer superior weatherability, design flexibility for complex profiles, and the longevity required for modern sustainable buildings. This technology empowers you to deliver glazing solutions that are as reliable as they are aesthetically refined.

3.3、Specialized Industrial and Appliance Seals

In the realm of specialized industrial and appliance seals, your requirements are exceptionally demanding. These seals must withstand aggressive chemicals, extreme temperatures, high pressures, or prolonged mechanical stress. A pin extruder is your key to manufacturing these critical components, as it allows you to co-extrude a composite structure where a soft, sealing layer is perfectly bonded to a rigid, load-bearing carrier in a single, continuous process.

You can design seals with a hard rubber or thermoplastic core for structural integrity, enveloped by a softer, highly conformable rubber layer for an impeccable seal. This is vital for industrial machinery, where seals prevent lubricant leakage and contaminant ingress, and for heavy-duty appliances like commercial dishwashers or compressors that face cyclic thermal and pressure loads.

Furthermore, the precision of a pin extruder enables you to integrate complex profiles with lips, bulbs, and hollow chambers directly into the seal strip. This capability allows you to create multi-functional seals for industrial doors, access panels, and high-end appliances that require both a robust physical barrier and superior acoustic or thermal insulation properties in one integrated part.

By utilizing a pin extruder, you gain the flexibility to tailor material combinations on-the-fly. You might pair a chemical-resistant EPDM with a low-compression-set silicone, or a耐磨NBR with a reinforcing thermoplastic. This material versatility, combined with precise dimensional control, ensures the seals you produce deliver long-term reliability, reducing maintenance cycles and failure rates for your end-users.

3.4、Custom Medical and Electronic Sealing Components

In the medical and electronics sectors, your sealing requirements are exceptionally demanding. These industries rely on pin extruders to produce custom composite rubber seal strips that meet strict standards for biocompatibility, chemical resistance, electrical insulation, and ultra-precise dimensional tolerances. The ability to co-extrude or compound different elastomers in a single profile is non-negotiable here.

For medical devices, you need seals that are not only effective but also safe for prolonged human contact. A pin extruder allows you to integrate a soft, skin-compatible silicone layer with a firmer, supportive EPDM or fluorosilicone core in one seamless process. This creates composite seals for syringe plungers, respiratory masks, dialysis equipment, and implantable device housings that offer both superior sealing performance and patient comfort.

In electronics, your challenges involve miniaturization and protection against environmental factors. Pin extruders enable the production of complex seal strips with conductive filaments for EMI shielding, or with varying hardness zones for cable grommets and connector seals. You can achieve precise, void-free extrusion of fluorocarbon or silicone composites that provide long-term protection against moisture, dust, and corrosive agents in sensitive electronic assemblies.

The precision and consistency of a modern pin extruder give you direct control over the material distribution within the seal's cross-section. This is critical when you are engineering a component where one part of the seal must be highly compressible while another section provides structural rigidity, all within a single, integrated manufacturing step, eliminating secondary bonding operations and potential failure points.

4、Selecting the Right Pin Extruder for Your Needs

When selecting the right pin extruder for your composite rubber seal strip production, several critical factors must align with your specific needs. First, assess the complexity of your seal profiles and the composite materials you plan to use. A high-performance pin extruder, like those engineered by APEX, excels in processing multi-component rubber compounds with precision, ensuring uniform blending and structural integrity in the final seal. You should also consider production volume and desired automation level. APEX's intelligent systems, developed from their provincial engineering center, offer advanced control for consistent quality and reduced waste, which is vital for serving demanding sectors like automotive and construction. Furthermore, evaluate the supplier's global support and customization capabilities. As a company with a presence in over 30 countries, APEX provides tailored solutions and reliable service, ensuring your investment enhances both product performance and long-term operational efficiency. Ultimately, the right choice balances technical prowess with practical support to secure your competitive edge.

4.1、Assessing Your Material and Profile Complexity

Your first step in selecting a pin extruder is a thorough analysis of the composite materials you intend to process. You must identify the specific rubber compounds, their hardness, viscosity, and any fillers or reinforcing agents like carbon black or fibers. The pin extruder's primary strength is its ability to homogenize and compound these diverse materials in-line. Therefore, understanding their compatibility and the required mixing intensity is paramount to ensure the final seal strip has uniform properties throughout its cross-section.

Next, you need to evaluate the geometric and functional complexity of the seal strip profile you aim to produce. Is it a simple solid shape, or does it incorporate complex internal voids, multiple material layers (co-extrusion), or integrated metal/plastic reinforcements? The pin extruder's design, particularly the number and arrangement of pins in the barrel and the sophistication of the die head, must match this complexity. More intricate profiles demand extruders with greater process control and flexibility to manage different material flow paths and pressures.

Consider the required production volume and tolerance levels. High-volume runs of precision seals justify investing in a pin extruder with advanced control systems for temperature, pressure, and line speed. These systems ensure consistency from batch to batch, minimizing waste and rework. For profiles with tight dimensional tolerances, the extruder's ability to maintain stable, pulsation-free output is non-negotiable.

Finally, assess future needs. Will you likely expand your product line to include new materials or more complex profiles? Choosing a pin extruder with a modular design or scalability allows for future upgrades. This foresight protects your investment and provides the agility to adapt to evolving market demands without requiring a complete machinery overhaul.

4.2、Evaluating Output Capacity and Floor Space

When evaluating output capacity, you must first align the extruder's capabilities with your production targets. Consider both the maximum throughput (measured in kilograms or meters per hour) and the consistency of that output across different composite formulations. A machine that excels with a single compound may struggle with a complex multi-material profile, leading to bottlenecks. Your goal is to find a pin extruder whose design—particularly the screw configuration, barrel heating zones, and pin mixing system—is optimized for your specific material blend and desired line speed, ensuring you can meet demand without sacrificing seal quality.

Floor space is a critical, often underestimated factor. A pin extruder line includes not just the extruder itself but also the downstream equipment: cooling tanks, haul-offs, cutters, and possibly vulcanization ovens. You need to assess the complete footprint. Modern compact designs with vertical or L-shaped layouts can save significant space compared to traditional horizontal lines. Evaluate if the supplier offers integrated solutions that minimize the overall length, allowing you to fit a high-capacity line into a constrained production area, thereby optimizing your factory layout and workflow efficiency.

The relationship between output and space is not linear. A higher-output machine might have a larger footprint, but its increased efficiency could reduce the number of production lines you need, ultimately saving space. Conversely, opting for a smaller machine to save floor space might force you to run multiple shifts to meet output, increasing operational complexity. You should perform a total cost of ownership analysis that weighs the capital cost, energy consumption per unit produced, and labor requirements against the physical space occupied to make the most economically sound decision for your sealing strip manufacturing.

4.3、Prioritizing Energy Efficiency and Automation

When you evaluate a pin extruder for composite rubber seal strips, energy efficiency is not just a cost-saving measure; it's a core component of operational sustainability and long-term profitability. Modern pin extruders incorporate advanced drive systems, such as servo motors and variable frequency drives (VFDs), which precisely match power consumption to the actual processing demand. This drastically reduces idle energy waste compared to older, constantly running systems. You should look for features like optimized barrel heating with efficient insulation and intelligent thermal control loops that minimize heat loss, directly lowering your electricity bills and reducing your carbon footprint.

Automation is the logical partner to energy efficiency, transforming your production line from a manual operation into a highly reliable, consistent process. A well-automated pin extruder integrates with downstream equipment—like cooling systems, cutting units, and packaging lines—through a centralized Programmable Logic Controller (PLC) or Human-Machine Interface (HMI). This allows you to set, monitor, and adjust all critical parameters—temperature profiles, screw speed, pin configuration, and haul-off speed—from a single console. For you, this means repeatable product quality, minimal human error, and the ability to quickly switch between different seal strip profiles with saved recipes.

Prioritizing these aspects also enhances your workforce's productivity and safety. Automated material feeding systems ensure a consistent supply of composite rubber compounds, while automated dimensional monitoring with laser gauges provides real-time feedback, allowing for immediate corrections. This reduces material waste and prevents the production of out-of-spec seals. Furthermore, by automating repetitive and potentially hazardous tasks, you create a safer working environment and free up skilled operators to focus on supervision, quality control, and process optimization, thereby adding more value to your operation.

Ultimately, investing in an energy-efficient and automated pin extruder is an investment in future-proofing your manufacturing. It provides you with the data and control necessary for lean manufacturing practices, predictive maintenance, and integration into broader Industry 4.0 frameworks. The initial capital outlay is offset by lower operational costs, higher throughput, superior product consistency, and enhanced agility to meet evolving market demands for high-performance composite rubber seals.

4.4、Ensuring Reliable Service and Technical Support

When you invest in a pin extruder for composite rubber seal strips, you are not just purchasing a machine; you are entering into a long-term partnership with the supplier. The reliability and longevity of your production line heavily depend on the quality of service and technical support you receive. You need a partner who responds promptly to your inquiries and provides solutions that minimize downtime.

Before finalizing your decision, thoroughly evaluate the supplier's support structure. Inquire about the availability of on-site service engineers, the average response time for technical calls, and the comprehensiveness of their training programs for your operators. A reputable supplier will offer detailed documentation, including operation manuals, troubleshooting guides, and maintenance schedules tailored to your specific model.

Furthermore, assess the availability of spare parts. A robust global supply chain for genuine components is non-negotiable. You should confirm that critical wear parts and proprietary components are stocked and can be delivered swiftly to your facility. This proactive approach prevents extended production halts and ensures your extruder maintains its precision and output quality over years of operation.

Finally, consider the supplier's commitment to continuous improvement. Do they offer software updates or retrofits for older models? Can they provide expert consultation for process optimization as your product portfolio evolves? Choosing a supplier with a forward-thinking support philosophy safeguards your investment and keeps your sealing solutions at the forefront of technology.

Investing in a pin extruder for composite rubber seal strips is a strategic decision that elevates your manufacturing capabilities. It empowers you to create superior products with consistent quality, reduce material waste, and respond flexibly to market demands. As industries continue to push for higher performance and sustainability, this technology stands as a key enabler for future growth.

We hope this guide has provided you with valuable insights and clarity on how this advanced extrusion process can benefit your specific applications. The journey towards more efficient and innovative seal production starts with the right equipment and knowledge.

When seeking a reliable partner for such advanced machinery, consider APEX - Qingdao Aipake Machinery Technology Co., Ltd. Founded in 2014, APEX is a high-tech enterprise specializing in the R&D, manufacturing, and sales of high-end rubber and plastic machinery. With a provincial-level engineering center and an intelligent production base, we are committed to delivering advanced, energy-saving, and intelligent industrial solutions. Our expertise spans across precision extrusion systems, serving over a thousand leading clients in electronics, automotive, medical, and construction sectors across more than 30 countries globally.