NBR/PVC Sheathing & Profile Production Line

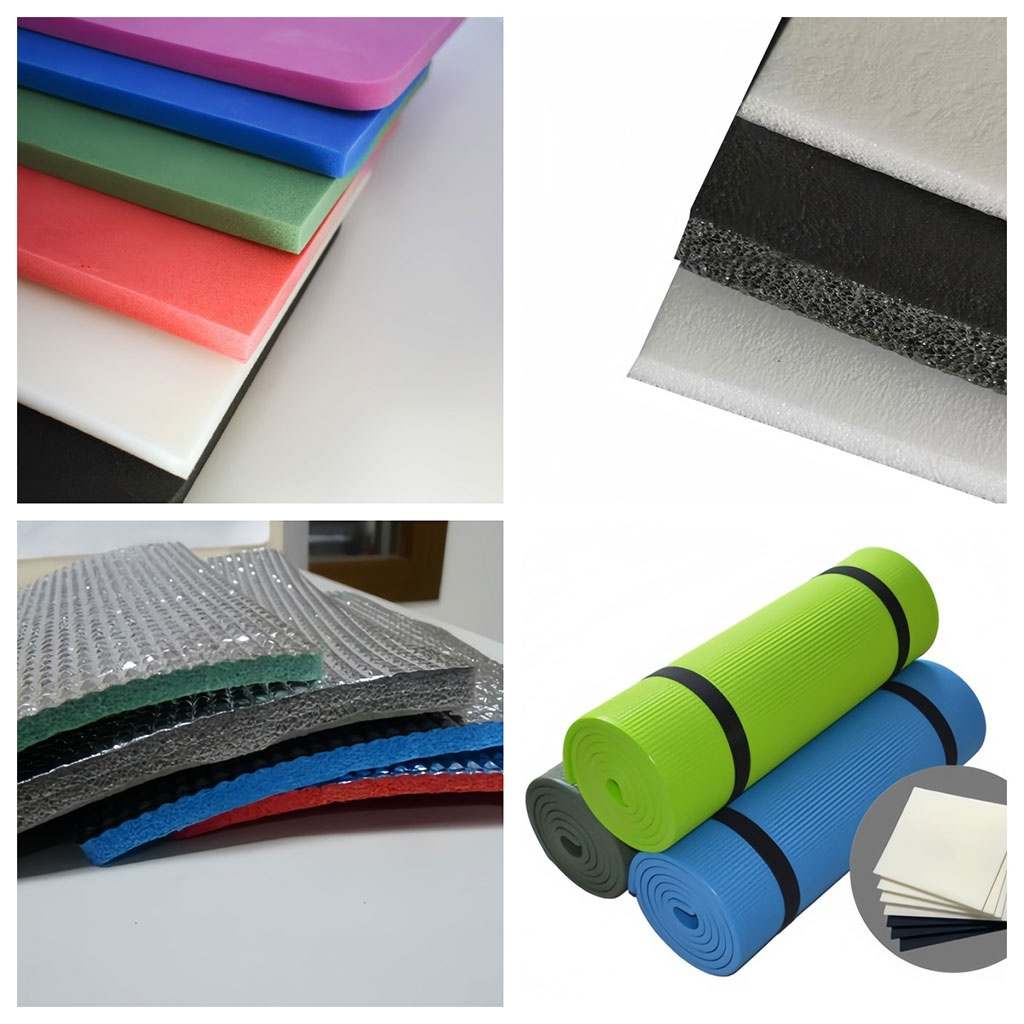

I. Product Description

The NBR/PVC sheathing line is specialized equipment for producing protective sheaths for器械 and cables. It integrates advanced automation control and precise processes to ensure high-quality, high-performance sheath products.

Featuring modular design, it can be flexibly configured for various specifications, widely used in wire & cable, medical devices, and industrial equipment.

Core Advantages: High automation, high efficiency, stable quality, easy operation/maintenance, low energy consumption.

II. Equipment Advantages (Core Selling Points)

Turnkey Service

We provide comprehensive turnkey solutions:

Equipment Supply: Full production line, reliable performance.

Special Formulations: Optimized NBR/PVC recipes per requirements.

Process Technology: Complete production process and guidance.

After-sales Support: Installation, commissioning, training, long-term tech support.

Value-added Services: OEM customization, permanent online video support.

III. Technical Parameters

| Parameter Name | Specification | Unit | Remarks |

| Line Speed | 10-50 | m/min | Adjustable |

| Applicable Diameter | 5-50 | mm | Customizable |

| Sheath Thickness | 0.5-3.0 | mm | Adjustable |

| Extruder Model | SJ-65/30 | - | High Efficiency |

| Heating Power | 15 | kW | Zoned Control |

| Cooling Method | Water Cooling | - | Sectional Cooling |

| Control System | PLC + Touch Screen | - | Intelligent Control |

| Total Power | 45 | kW | Excl. Auxiliary |

| Dimensions | 25×3×2.5 | m | L×W×H |

IV. Formulation Table

| Material Name | Ratio (Parts) | Function | Supplier |

| PVC Resin | 100 | Base Material | Domestic Brand |

| NBR Rubber | 20-40 | Toughening | Import/Domestic |

| Plasticizer | 30-50 | Flexibility | Eco-friendly |

| Stabilizer | 3-5 | Heat Stability | Lead-free |

| Filler | 10-30 | Cost/Performance | CaCO3/Talc |

| Lubricant | 0.5-1.5 | Flowability | Internal/External |

| Colorant | 1-3 | Coloring | As Required |

| Other Additives | 2-5 | Special Functions | Antioxidant, etc. |

Note: General formulation; customizable per requirements.

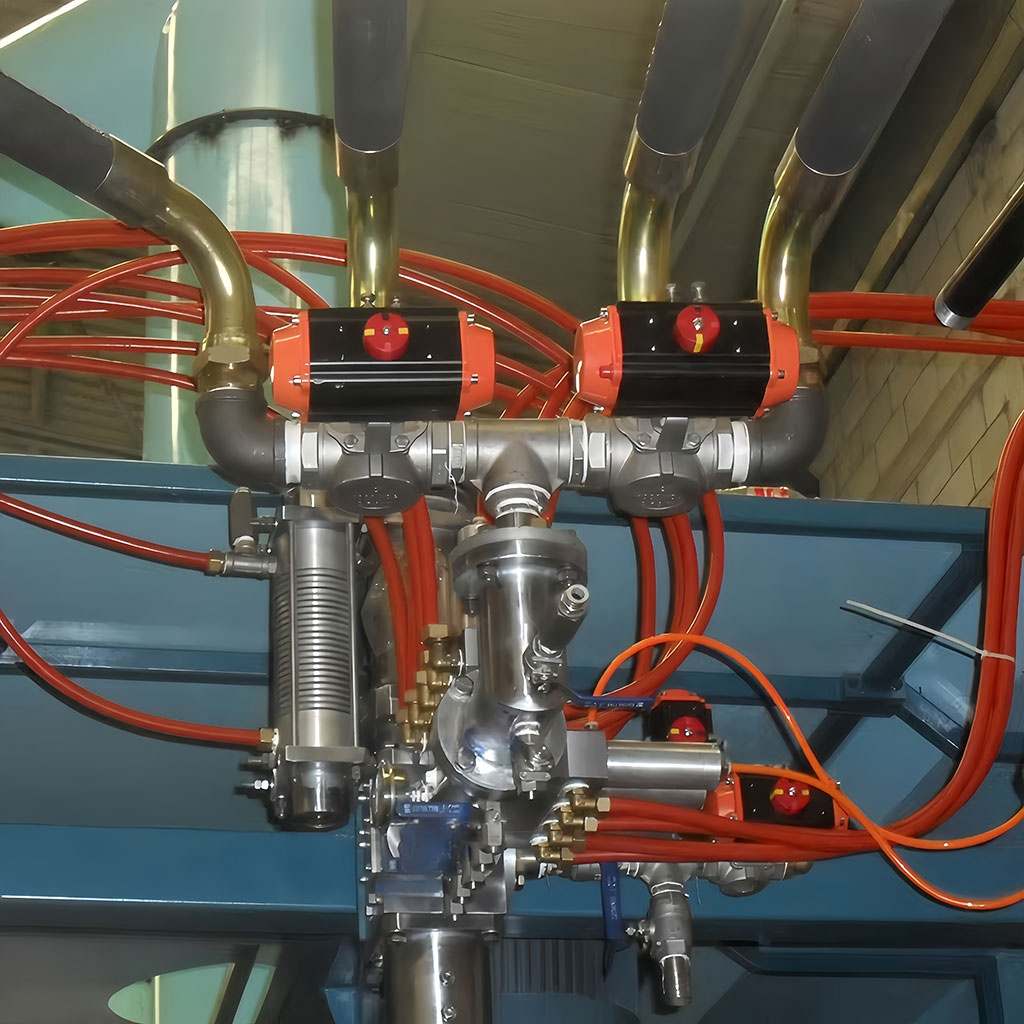

V. Equipment List

| No. | Equipment Name | Model | Qty | Main Function |

| 1 | Auto Feeding System | AS-500 | 1 set | Material Conveying |

| 2 | High-speed Mixer | SHR-200 | 1 | Pre-mixing |

| 3 | Twin-screw Extruder | SJZ-65/132 | 1 | Plasticizing |

| 4 | Sheath Die | Custom | Multiple | Shaping |

| 5 | Cooling Tank | 6m | 1 set | Cooling |

| 6 | Haul-off | QY-1000 | 1 | Pulling |

| 7 | Auto Winder | SJ-1600 | 1 | Winding |

| 8 | Control System | PLC Control | 1 set | Automation |

| 9 | Auxiliary Equipment | - | 1 batch | Testing, etc. |

VI. Process Flow

Material Prep → High-speed Mixing → Extrusion → Sheath Forming → Cooling → Haul-off → Online Inspection → Winding/Packaging

Features: Efficient, automated, stable quality, low energy, easy operation.

VII. Applications

Wire & Cable: Power, communication, control cables.

Medical Devices: Equipment cables, tubes.

Automotive: Wiring harnesses, pipe protection.

Home Appliances: Power cords, internal wires.

Industrial Equipment: Machine cable protection.

Construction: Building wiring, conduit protection.

Customization: Tailored solutions available.

VIII. About APEX

Headquarters: Qingdao, China. Founded: 2014.

Scale: 3 factories, 2 industrial parks, 100+ employees, 10+ years experience.

Market Distribution: Domestic 35%, North America 9%, South Asia 7%, South America 7%, Eastern Europe 6%, Middle East 5%.

Service Philosophy

Quality First: ISO9001 system, reliable products.

Turnkey Projects: Full service from selection to training.

Full Tech Support: Pre-sales, during-sales, after-sales, lifetime service.

Customization: OEM, personalized solutions.

Permanent Online Video Support: 7x24 response.