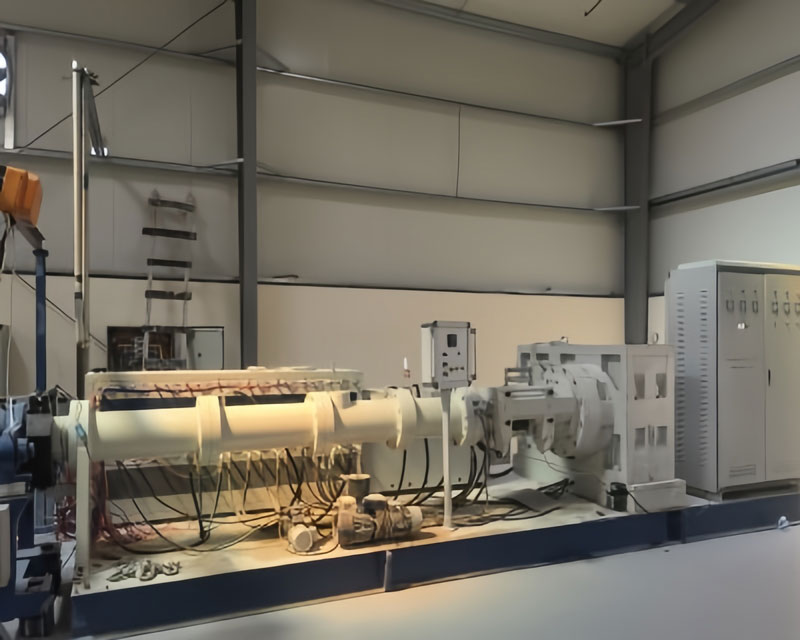

Rubber Pin Type Extruder

High Efficiency & Energy Saving · Excellent Plasticizing Effect · Low Rubber Temperature

One, Product Description

The rubber pin type extruder is a highly efficient and energy-saving rubber mixing and extrusion equipment. It significantly improves the plasticizing quality, mixing uniformity, and extrusion efficiency of the rubber compound by installing multiple rows of pins on the barrel of a traditional extruder, which subject the rubber to intense shearing, stirring, and reshaping, while effectively controlling the rubber temperature. It is an indispensable key equipment in the modern rubber processing industry.

Working Principle: The pin type extruder installs several rows of pins on specific sections of the barrel. Under the action of these pins, the rubber compound undergoes transverse movement,分流运动 (diversion flow movement), and rotational movement, achieving efficient mixing and extrusion.

Two, Equipment Advantages (Core Selling Points)

Excellent Mixing Effect: The multiple rows of pins installed on the barrel penetrate deep into the rubber compound, disrupting its laminar flow, generating strong diversion, shear, and rotational movements, effectively breaking up rubber lumps, resulting in more uniform dispersion of fillers and compounding agents, and excellent plasticizing effect.

High Extrusion Efficiency and Stability: The stirring action of the pins reduces backflow of the rubber in the screw channel, improving conveying efficiency, thus the output is greater than that of ordinary cold-feed extruders. The extruded rubber has good density, stable dimensions, and low shrinkage.

Low-Temperature Extrusion, Energy Saving and High Efficiency: Achieving the same plasticizing effect, the pin-type structure generates less heat compared to relying solely on screw shear, avoiding the risk of scorching due to overheating, improving product quality, while reducing energy consumption.

Strong Adaptability: Capable of processing various rubber compound formulas, and also has good adaptability for compounds that are difficult to feed and mix (e.g., high-fill formulations).

Intelligent Control: Equipped with advanced temperature control system and electrical control system, allowing precise control of process parameters such as zone temperatures and screw speed. Easy to operate, high degree of automation.

Provide Turnkey Service:

We provide full turnkey project services from equipment design, manufacturing, installation, commissioning to personnel training, ensuring customers can quickly start production and achieve expected results.

Three, Technical Parameter Table

| Parameter Name | Unit | Model SJ-90 | Model SJ-120 | Model SJ-150 |

| Screw Diameter | mm | 90 | 120 | 150 |

| Length-Diameter Ratio (L/D) | - | 12:01 | 14:01 | 16:01 |

| Production Capacity | kg/h | 300-500 | 600-900 | 1000-1500 |

| Main Motor Power | kW | 75 | 132 | 200 |

| Screw Speed | rpm | 5-45 | 5-40 | 5-35 |

| Heating Method | - | Electric Heating + Water Cooling (Zoned Control) | Electric Heating + Water Cooling (Zoned Control) | Electric Heating + Water Cooling (Zoned Control) |

| Temperature Control Accuracy | ℃ | ±1 |

|

|

| Overall Dimensions(L×W×H) | m | 4.5×1.5×2.0 | 5.5×1.8×2.2 | 6.5×2.0×2.5 |

| Equipment Weight | t | Approx. 4.5 | Approx. 7.2 | Approx. 10.5 |

Four, Formulation Table

| Raw Material Name | Tire Tread Compound (phr) | Sealing Strip Compound (phr) | Waterproof Membrane Compound (phr) |

| Natural Rubber (NR) | 70 | 30 | 50 |

| Styrene-Butadiene Rubber (SBR) | 30 | 50 | 30 |

| Ethylene Propylene Diene Monomer (EPDM) | - | 20 | 20 |

| Carbon Black (N330) | 50 | 40 | 45 |

| Silica | 10 | 15 | 10 |

| Aromatic Oil | 8 | 12 | 10 |

| Zinc Oxide | 4 | 5 | 4 |

| Stearic Acid | 2 | 1.5 | 2 |

| Antioxidant | 2.5 | 2 | 2.5 |

| Accelerator | 1.2 | 1.5 | 1.2 |

| Sulfur | 1.8 | 2 | 1.8 |

Five, Equipment List

| No. | Equipment Name | Specification Model | Qty. | Remarks |

| 1 | Main Motor | Configured according to model | 1 unit | Variable Frequency Speed Control |

| 2 | Gear Reducer | Hardened Gear Reduction | 1 unit | Transmission Efficiency ≥96% |

| 3 | Feeding Device | Cold Feed | 1 set | With Safety Guard |

| 4 | Barrel | Bimetallic Liner | 1 set | Sectional, with Heating/Cooling |

| 5 | Screw | 38CrMoALA | 1 piece | Nitrided, Hardness HV≥950 |

| 6 | Pins | Special Alloy Steel | Multiple Rows | Adjustable Position |

| 7 | Die Head | Customized per product | 1 set | With Screen Pack Device |

| 8 | Temperature Control Unit | PID Intelligent Control | 1 set | Zoned Control, Accuracy ±1℃ |

| 9 | Electrical Control System | PLC + Touch Screen | 1 set | Siemens/Mitsubishi Brand |

| 10 | Machine Frame | Q235 Steel | 1 set | Surface Powder Coated |

| 11 | Hydraulic Screen Changer | Optional | 1 set | Quick Change, Non-Stop |

Six, Process Flow Chart

Rubber Pin Type Extruder Process Flow

Rubber Compound Preparation → Automatic Feeding → Pin Type Extruder Extrusion → Die Head Forming → Cooling & Sizing → Haul-Off → Cutting → Inspection → Packaging & Warehousing

Note: The actual flow chart should include more detailed equipment connections and process parameters.

Seven, Application Fields

Tire Manufacturing: Extrusion of semi-finished products like treads, sidewalls, apex strips, etc.

Sealing Products: Automotive door/window seals, building seals, etc.

Building Materials: Waterproof membranes, rubber waterstops, etc.

Hose & Belt Products: Various types of rubber hoses, conveyor belt cover compounds, etc.

Auxiliary Feeding: Can serve as the pre-feed equipment for calender lines.

Eight, About APEX

Headquarters: China Shandong, Founded in 2014, Scale: 3 branch factories, 2 major industrial parks, 100+ employees, 10+ years professional experience

Market Distribution:Domestic: 35%,North America: 9%,South Asia/South America/Eastern Europe/Middle East: Each accounts for 7%~5%

Service Commitment:,Quality First, Turnkey Project,Full Process Technical Support,Support OEM Customization,Permanent Online Video Technical Support.