Production Process of High-Output Rubber Extruder for Waterstops: A Comprehensive Guide

Production process of high-output rubber extruder for waterstops is a critical topic for professionals in the construction and waterproofing industries. Understanding this process can help you make informed decisions about your equipment and production efficiency. In this article, we will walk you through every essential stage, from raw material preparation to final product testing.

You might be wondering what makes a high-output extruder so special for manufacturing waterstops. These specialized machines are designed to handle large volumes of rubber compounds consistently, ensuring that your waterstop profiles meet strict quality and durability standards. By optimizing the production process, you can significantly reduce waste and increase your overall output.

Whether you are a project manager, an engineer, or a business owner, grasping the intricacies of this process will empower you to enhance your production line. Let's dive into the details and explore how a well-executed production process can benefit your operations and end products.

1、Raw Material Preparation and Feeding

1.1、Selection and Quality Control of Rubber Compounds

1.2、Pre-conditioning and Mixing Techniques

1.3、Automated Feeding Systems for Consistency

2、Extrusion and Profile Forming

2.1、Screw and Barrel Design for High Output

2.2、Temperature and Pressure Control During Extrusion

2.3、Die Design and Calibration for Precise Waterstop Shapes

3、Cooling and Curing Stages

3.1、Efficient Cooling Methods to Stabilize Profiles

3.2、Vulcanization Processes for Enhanced Durability

3.3、Continuous Curing Lines for High-Volume Production

4、Cutting, Inspection, and Packaging

4.1、Precision Cutting to Required Lengths

4.2、Quality Checks for Dimensions and Physical Properties

4.3、Automated Packaging and Labeling for Shipment

1、Raw Material Preparation and Feeding

To begin the production process of a high-output rubber extruder for waterstops, you must first focus on raw material preparation and feeding. This initial stage is foundational, as the quality and consistency of the rubber compound directly determine the performance and durability of the final waterstop. At APEX (Qingdao Aipake Machinery Technology Co., Ltd.), our high-output extruders are engineered to handle precise feeding of various rubber materials, ensuring optimal dispersion and homogeneity. You need to carefully select and pre-process raw materials—such as natural or synthetic rubber, carbon black, plasticizers, and vulcanizing agents—before they are fed into the extruder's hopper. Our advanced feeding systems, developed through our省级工程技术中心 (provincial engineering technology center), guarantee accurate metering and consistent material flow, which is crucial for maintaining high output rates and minimizing defects in the extruded waterstop profiles. By mastering this step, you lay the groundwork for efficient, reliable production that meets the stringent demands of global construction and waterproofing projects.

1.1、Selection and Quality Control of Rubber Compounds

When selecting rubber compounds for your high-output extruder, you must prioritize materials that offer excellent resistance to water, chemicals, and environmental stress. Typically, synthetic rubbers like EPDM, neoprene, or nitrile are chosen for waterstop applications due to their superior durability and sealing properties. You need to ensure the compound formulation aligns with the specific performance requirements of the waterstop, such as flexibility, tensile strength, and long-term stability.

Quality control begins at the supplier level. You should establish strict specifications for raw material properties, including Mooney viscosity, hardness, and cure characteristics. Implementing a certificate of analysis (CoA) review for each batch is essential. This step verifies that the incoming rubber compound meets your predefined standards before it enters the production line, preventing inconsistencies that could lead to extrusion defects or product failure.

On-site testing is another critical layer of control. You can perform routine checks, such as measuring the compound's specific gravity and conducting small-scale extrusion trials. These tests help you confirm the material's processability in your specific extruder setup. By maintaining rigorous quality control from the start, you ensure a smooth, stable extrusion process and produce waterstops that consistently meet industry standards for waterproofing and structural integrity.

1.2、Pre-conditioning and Mixing Techniques

Pre-conditioning and mixing techniques are crucial for ensuring that your rubber compounds achieve the optimal consistency and homogeneity before entering the extruder. You must carefully control the temperature and shear forces during this stage to activate the polymers and distribute fillers, plasticizers, and vulcanizing agents evenly. This directly impacts the final waterstop's mechanical properties, such as tensile strength and elongation at break.

You typically begin by pre-heating the raw rubber and masterbatch in an internal mixer or on a two-roll mill. This step, known as mastication, softens the polymer chains, making them more receptive to other ingredients. For high-output production, you should aim for a precise temperature range to avoid premature vulcanization (scorching) while ensuring sufficient plasticity for the subsequent mixing phase.

Following pre-conditioning, you proceed to the intensive mixing stage. Here, you sequentially add carbon black, oils, antioxidants, and other additives. The key is to achieve a uniform dispersion without generating excessive heat. Modern mixers with intermeshing rotors and precise temperature control systems are essential for your high-output process, as they provide consistent shear and cooling, leading to a compound with minimal batch-to-batch variation.

After the intensive mix, you often transfer the compound to a downstream mixer or an open mill for final homogenization and cooling. This step, sometimes called 'dumping' or 'finishing,' allows you to adjust the compound's temperature to the ideal range for feeding into the extruder. Proper cooling is vital; feeding a compound that is too hot can cause processing issues in the extruder barrel, affecting dimensional stability and surface finish of the extruded waterstop profile.

Ultimately, mastering these pre-conditioning and mixing techniques allows you to produce a rubber compound with consistent viscosity and flow characteristics. This consistency is the foundation for stable, high-speed extrusion, enabling your high-output rubber extruder to produce long, continuous lengths of waterstop with uniform cross-section and superior performance properties.

1.3、Automated Feeding Systems for Consistency

Automated feeding systems are the backbone of consistency in your high-output rubber extruder line. They precisely meter and deliver the prepared rubber compound into the extruder's feed hopper, eliminating the variability inherent in manual loading. This ensures a constant, uninterrupted flow of material, which is fundamental for maintaining uniform pressure and temperature profiles within the extruder barrel.

These systems typically consist of conveyor belts or screw feeders that are synchronized with the extruder's screw speed. You can program them to deliver a specific feed rate, which directly correlates to your desired output and profile dimensions. This level of control prevents surging or starving the extruder screw, two common issues that lead to dimensional instability and defects in the final waterstop profile.

Furthermore, automated feeders often integrate with load cells or other weighing mechanisms for gravimetric or volumetric control. This allows for real-time monitoring and adjustment of the material input, guaranteeing that the exact formulation ratio is maintained throughout the production run. For you, this translates to batch-to-batch consistency that manual processes simply cannot achieve.

By implementing an automated feeding system, you not only enhance product quality but also improve operational safety and labor efficiency. It reduces human intervention at a critical stage, minimizes material spillage, and allows your operators to focus on monitoring the overall process rather than performing repetitive manual tasks. This investment directly contributes to the 'high-output' capability of your extruder system.

2、Extrusion and Profile Forming

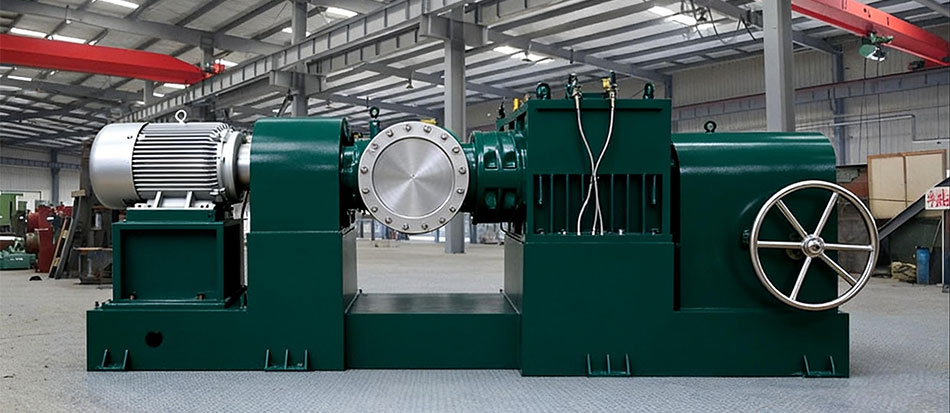

Following the meticulous preparation of raw materials, the extrusion and profile forming stage is where your high-output rubber extruder truly demonstrates its capabilities. At this critical phase, the pre-mixed and warmed rubber compound is fed into the extruder's barrel. As you operate an APEX extruder, you'll appreciate how its precision-engineered screw design and advanced temperature control systems work in unison. The screw rotates, conveying, compressing, and melting the rubber, forcing it through a specially designed die—the heart of profile forming. For waterstops, this die is custom-made to create the exact cross-sectional shape required, whether it's a dumbbell, center bulb, or other complex geometry essential for effective sealing in construction joints.

The "high-output" aspect comes from the machine's optimized throughput and stability. APEX's focus on advanced, energy-efficient, and intelligent industrial solutions ensures that the extrusion process maintains consistent pressure and temperature, resulting in a continuous, uniform profile with precise dimensions. This consistency is paramount for waterstops, as any variation can compromise their waterproofing integrity. By leveraging such technology, you can achieve a seamless production flow, maximizing output while adhering to the stringent quality standards demanded by the global construction industry.

2.1、Screw and Barrel Design for High Output

When you aim for high output in waterstop production, the heart of your rubber extruder lies in its screw and barrel design. This is not just about pushing material through; it's about creating a precise, controlled, and efficient flow of the rubber compound. The screw's geometry directly dictates the melting, mixing, and pumping efficiency, which are paramount for consistent, high-volume output.

For your high-output application, you will typically require a screw with a deep channel and a specific compression ratio optimized for rubber compounds. A longer L/D (Length-to-Diameter) ratio is often employed to ensure sufficient residence time for proper plastication and homogenization of the material before it exits the die. This design minimizes pressure fluctuations and ensures a stable, continuous extrusion of the waterstop profile, which is critical for maintaining dimensional accuracy over long production runs.

The barrel must complement the screw's action. It is usually lined with a hardened, wear-resistant material to withstand the abrasive nature of filled rubber compounds used in waterstops. Effective temperature control zones along the barrel are crucial for you. They allow precise management of the rubber's viscosity, preventing premature curing or scorching while ensuring the compound is at the ideal temperature for smooth extrusion through the profile die.

Ultimately, the synergy between the screw's conveying, compression, and metering sections and the barrel's supportive environment enables your extruder to deliver the high, consistent throughput necessary for profitable waterstop manufacturing. Investing in a well-engineered screw and barrel system is investing in the reliability and productivity of your entire production line.

2.2、Temperature and Pressure Control During Extrusion

Temperature control during extrusion is not just a setting; it's a dynamic process that directly influences the molecular behavior of your rubber compound. You must maintain a precise temperature profile along the barrel and die head. If the temperature is too low, the rubber's viscosity increases, leading to excessive motor load, poor flow, and potential die blockage. Conversely, if the temperature is too high, you risk scorching or pre-vulcanization of the rubber, which degrades the physical properties of the final waterstop, making it brittle and prone to failure.

Pressure control is equally critical and intrinsically linked to temperature. The extruder screw generates pressure to push the plasticized rubber through the die. You need to monitor and control this pressure to ensure a consistent, dense profile without voids or air pockets. Insufficient pressure results in an under-compacted, porous waterstop with weak structural integrity. Excessive pressure can cause dimensional inaccuracies, die swell issues, and even damage the extruder or die itself.

The synergy between temperature and pressure defines your extrusion stability. A stable melt temperature ensures consistent viscosity, which in turn leads to stable extrusion pressure. You should use closed-loop control systems that automatically adjust heater bands and screw speed based on real-time sensor feedback. This automation helps you maintain the "sweet spot" where the rubber flows smoothly and fills the die cavity perfectly, producing a waterstop with uniform cross-section and excellent surface finish.

For high-output production, these controls become even more vital. As you increase screw speed to boost output, frictional heat generation rises. You must actively counteract this by adjusting cooling systems in the barrel to prevent thermal runaway. Precise control allows you to maximize output speed without sacrificing quality, ensuring every meter of waterstop extruded meets the required specifications for density, dimensional tolerance, and material homogeneity.

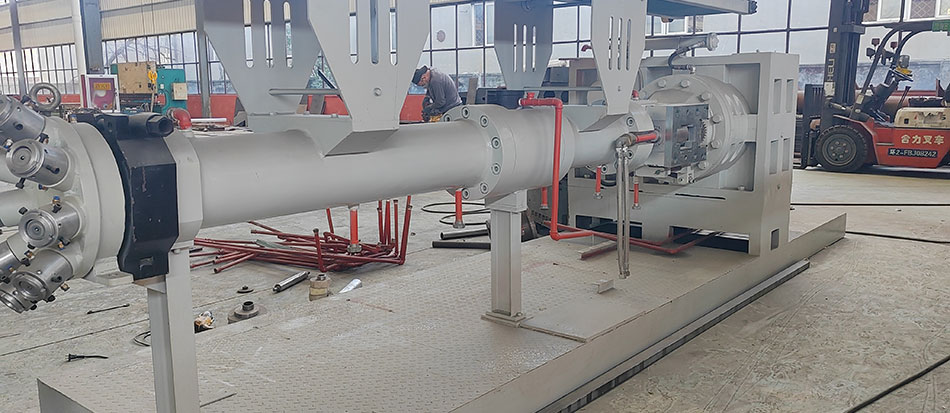

2.3、Die Design and Calibration for Precise Waterstop Shapes

Die design is the heart of achieving precise waterstop shapes in your high-output extrusion process. For you, this means the die must be meticulously engineered to transform the homogeneous, heated rubber compound from the barrel into the exact cross-sectional profile required. The design must account for material flow characteristics, swell (die swell) as the rubber exits the die, and the final dimensional tolerances specified for the waterstop. A well-designed die ensures uniform material distribution, preventing weak spots or variations in thickness that could compromise the waterstop's sealing performance.

Calibration follows immediately after extrusion and is critical for locking in the precise shape. As the hot, soft profile exits the die, it enters a calibration unit—often a vacuum calibration tank with precisely machined sizing plates or molds. For you, this stage is about cooling and shaping under controlled conditions. The vacuum pulls the extrudate firmly against the cool calibration surfaces, rapidly setting the rubber's outer dimensions to the exact specifications. Proper calibration eliminates deformations and ensures the intricate details of the waterstop, such as bulbous centers or anchoring fins, are formed accurately and consistently.

The synergy between die design and calibration directly impacts your production efficiency and product quality. An imprecise die will force the calibration unit to work harder, potentially leading to increased scrap rates and slower line speeds. Conversely, a perfectly designed die paired with precise calibration allows your high-output extruder to run at optimal speed while maintaining dimensional accuracy. For you, investing in high-quality, custom-designed dies and well-maintained calibration equipment is non-negotiable for producing reliable, specification-compliant waterstops in large volumes.

Finally, ongoing monitoring and fine-tuning are part of the process. You must regularly check the extruded profiles against master gauges and adjust calibration parameters like vacuum level, cooling water temperature, and puller speed. This proactive approach ensures long-term consistency, minimizes material waste from out-of-spec production, and guarantees that every meter of waterstop leaving your line meets the stringent demands of modern waterproofing applications.

3、Cooling and Curing Stages

After the rubber compound is precisely shaped by the extruder's die head, the continuous profile enters the critical cooling and curing stages. For you, ensuring these stages are optimized is key to achieving the dimensional stability and physical properties required for high-performance waterstops. At APEX, our high-output extruders are engineered to integrate seamlessly with advanced cooling systems, such as multi-zone water baths or air-cooling tunnels. This controlled cooling process prevents deformation and internal stresses, setting the profile for the final cure.

The subsequent curing, often in a continuous vulcanization line, is where the rubber's molecular chains cross-link to develop its ultimate strength, elasticity, and long-term water resistance. Our equipment is designed to provide precise temperature and speed control throughout this stage, ensuring a consistent and complete cure for every meter of waterstop produced. This attention to detail in cooling and curing directly translates to the reliability of your final product, minimizing defects and supporting the high-output promise of your production line.

3.1、Efficient Cooling Methods to Stabilize Profiles

Efficient cooling is the first critical step after the waterstop profile exits the extruder die. You must rapidly remove the heat from the rubber to stabilize its shape and prevent deformation under its own weight. This is typically achieved using a multi-zone cooling trough or a series of water baths. The initial zone uses water at a higher temperature to avoid thermal shock, which can cause internal stresses or surface defects in the profile.

As the profile moves through subsequent cooling zones, the water temperature is gradually lowered. This controlled, staged cooling process ensures that the rubber cools uniformly from the outside in. For you, this means the cross-sectional geometry of the waterstop—be it a dumbbell, center bulb, or any complex design—remains precise and consistent along its entire length, which is fundamental for its sealing performance in concrete joints.

The length of the cooling line is directly proportional to your extruder's output speed. A high-output machine requires a sufficiently long cooling path to provide adequate residence time for the rubber to cool below its crystallization or vulcanization initiation temperature. You should ensure the cooling system has sufficient capacity and temperature control to match your production rate, otherwise, you risk profile distortion or an unstable production line.

Beyond water baths, forced air cooling or misting systems can be employed as supplementary methods, especially for thicker profiles. The key for your operation is to establish a cooling regimen that brings the extrudate to a stable, ambient temperature efficiently, preparing it perfectly for the next crucial stage: curing.

3.2、Vulcanization Processes for Enhanced Durability

Vulcanization is the chemical process that transforms the soft, pliable rubber compound from the extruder into a tough, elastic, and durable waterstop. For you, achieving enhanced durability means ensuring the sulfur cross-links form a robust three-dimensional network within the polymer chains. This network is what gives the final product its resistance to permanent deformation, environmental stress, and long-term water immersion.

In your high-output production line, vulcanization typically follows the extrusion and initial cooling. You have several methods at your disposal. Continuous vulcanization in a hot-air tunnel or a molten salt bath is highly efficient for your high-volume needs. The extruded profile passes through a precisely controlled heated zone, where temperature and exposure time are critical parameters you must monitor closely to achieve uniform curing throughout the cross-section.

The choice of vulcanization system—whether using sulfur, peroxides, or other agents—directly impacts the waterstop's properties. For instance, an efficient sulfur system provides excellent tensile strength and elasticity, which is vital for your waterstops to accommodate structural movements. You need to optimize the recipe and curing conditions to balance cure rate with the final physical properties, ensuring no under-cure (leading to softness) or over-cure (leading to brittleness) occurs.

Finally, implementing precise process control is non-negotiable for you. Modern systems integrate sensors and feedback loops to maintain consistent temperature and speed. This control guarantees that every meter of waterstop produced on your high-output extruder has the same enhanced durability, meeting the stringent performance standards required for critical infrastructure projects.

3.3、Continuous Curing Lines for High-Volume Production

When you're aiming for high-volume production of waterstops, a continuous curing line is not just an option; it's a necessity for maintaining the output pace set by your high-output extruder. This system is designed to seamlessly receive the extruded rubber profile and carry it through a controlled, uninterrupted thermal process that vulcanizes the rubber, transforming it from a pliable state into its final, durable, and dimensionally stable form.

The core advantage for you lies in its efficiency and consistency. Unlike batch curing methods, a continuous line operates non-stop. The extruded profile travels on a conveyor through a long, multi-zone curing tunnel or a series of heated platens. You can precisely control the temperature and speed in each zone, ensuring that every millimeter of the waterstop receives the exact heat history required for optimal cross-linking of the polymer chains. This eliminates the risk of under-cured or over-cured sections, which are common quality issues in discontinuous processes.

For high-output operations, the synchronization between the extruder's exit speed and the curing line's conveyor speed is critical. Modern systems are integrated, allowing for real-time adjustments to maintain a constant, tension-free flow of material. This prevents deformation or stretching of the soft, uncured rubber, ensuring the final product's geometry—be it dumbbell, center bulb, or any complex profile—remains perfectly within your specified tolerances.

Furthermore, continuous curing lines often incorporate cooling zones at the discharge end. This controlled cooling phase is vital. It halts the vulcanization process at the right moment and brings the waterstop down to a handling temperature without causing thermal shock or internal stresses that could compromise its long-term performance. The result for you is a continuous stream of finished, ready-to-ship product, dramatically increasing your plant's throughput and reducing work-in-progress inventory.

4、Cutting, Inspection, and Packaging

After the rubber waterstop profile is successfully extruded and vulcanized, the final and equally crucial stage in the production process of a high-output rubber extruder for waterstops is cutting, inspection, and packaging. At this point, you have a continuous length of high-quality product, and precision here ensures that every piece delivered to your construction site meets the exact specifications. Using advanced CNC cutting systems, the continuous profile is cut to the precise lengths you require, ensuring clean, burr-free ends that are ready for installation.

Following cutting, a rigorous inspection process is implemented. This is where the reliability of equipment from companies like APEX (Qingdao Aipake Machinery Technology Co., Ltd.) proves its value. Their high-output extruders are engineered for consistency, which simplifies quality control. You or your quality team will inspect the cut pieces for dimensional accuracy, surface integrity, and the absence of any defects like bubbles or impurities. This step is vital to guarantee the waterstop's performance in sealing construction joints against water ingress.

Finally, the approved waterstops are carefully packaged. They are typically coiled or stacked in a manner that prevents deformation during transportation and storage. Proper labeling with batch numbers, specifications, and handling instructions is standard. This meticulous attention to detail in the final stages, supported by intelligent and reliable machinery, ensures that the high-output production process translates directly into dependable, ready-to-use products for your global construction projects, upholding the reputation for excellence that leaders in the industry demand.

4.1、Precision Cutting to Required Lengths

Once the continuous profile of the waterstop exits the extruder's die head and is cooled, it must be precisely cut to the specific lengths required for your construction projects. This is a critical step where accuracy directly impacts installation efficiency and material waste. You cannot afford to have waterstop segments that are too short or inconsistently long, as this leads to on-site joining issues and potential waterproofing failures.

Modern high-output lines typically employ synchronized flying cutters or servo-driven cutting systems. These systems track the moving extrudate and make clean, square cuts at predetermined intervals without stopping the extrusion line. This ensures a continuous production flow, which is essential for maintaining the high output that defines this equipment. The cutting length is programmed based on your project specifications, allowing for flexibility between different orders.

The quality of the cut is paramount. A clean, burr-free cut ensures that when two ends are joined on-site—whether by vulcanization or using adhesive—the connection is seamless and strong. Any deformation or ragged edge from a poor cut can create a weak point in the waterproofing barrier. Therefore, maintaining sharp blades and precise mechanical alignment in the cutting unit is part of your routine operational checklist.

For you, the end-user, this precision translates directly to project readiness. Receiving waterstops pre-cut to the exact lengths needed simplifies logistics, reduces on-site labor for trimming, and minimizes scrap. It's a value-added step in the production process that underscores the efficiency and client-focused design of a high-output rubber extruder system for waterstops.

4.2、Quality Checks for Dimensions and Physical Properties

In the production process of a high-output rubber extruder for waterstops, quality checks for dimensions and physical properties are non-negotiable. You must verify that every meter of extruded profile conforms precisely to the specified cross-sectional geometry. This involves using calibrated tools like calipers, micrometers, and profile projectors to measure critical dimensions such as overall width, height, bulb diameters, and fin thicknesses. Any deviation beyond the defined tolerances can compromise the waterstop's ability to form a proper seal in the concrete joint, leading to potential failure.

Beyond dimensional accuracy, you need to rigorously test the physical properties of the rubber compound. Standard tests include checking the hardness (Shore A), tensile strength, elongation at break, and compression set. These properties directly correlate with the waterstop's performance under long-term compression, its ability to accommodate joint movement, and its resistance to environmental stressors. A high-output line must integrate these checks at regular intervals to ensure batch-to-batch consistency.

Furthermore, you should conduct visual and tactile inspections for surface defects like porosity, blisters, or contamination. These imperfections, often stemming from issues in the mixing or extrusion stages, can create weak points. Implementing Statistical Process Control (SPC) charts for key dimensions and properties allows you to monitor process stability and predict trends, enabling proactive adjustments to the extruder's parameters before non-conforming product is produced.

Finally, remember that quality assurance is integral to the entire production process. The data gathered from these checks not only confirms the acceptability of the current batch but also feeds back into the system. It helps you fine-tune the raw material formulation, screw speed, temperature profiles, and die design of your high-output extruder, creating a closed-loop system dedicated to continuous improvement and reliable, high-quality waterstop manufacturing.

4.3、Automated Packaging and Labeling for Shipment

Automated packaging and labeling represent the final, critical step in the production process of your high-output rubber extruder for waterstops. This stage ensures that the precisely cut and inspected profiles are protected, organized, and ready for efficient shipment to your construction sites. By implementing automation here, you eliminate human error in counting and labeling, significantly boost packing speed to match your extruder's high output, and present a professional, standardized product to your clients.

Your automated system typically begins by receiving the bundled waterstops from the inspection station. Robotic arms or conveyor-fed systems then place the bundles into pre-formed cardboard boxes or onto sturdy pallets, depending on the order specifications. The system is programmed to pack a precise quantity per box, ensuring consistency and simplifying inventory management for both you and your customer. This precision is crucial for large projects where material reconciliation is essential.

Following the packing sequence, the integrated labeling system springs into action. It automatically prints and applies labels containing all vital information: product code, batch number, length, quantity, production date, and your company details. This data is often pulled directly from your production management software, guaranteeing 100% accuracy. Barcodes or QR codes are also included, enabling easy scanning for warehouse logistics and on-site verification. This traceability is a key quality assurance feature for your clients.

The benefits for your operation are substantial. Automated packaging maintains the integrity of the waterstops, preventing damage during handling and transit. It dramatically increases your line's overall throughput, ensuring that the high output of your extruder is not bottlenecked at the final stage. Furthermore, it reduces labor costs and minimizes physical strain on workers. For your customers, it translates to receiving correctly labeled, undamaged goods that are easy to identify, handle, and install, thereby enhancing their trust in your supply chain reliability.

In summary, mastering the production process of high-output rubber extruder for waterstops is key to achieving superior product quality and operational efficiency. By paying attention to each stage—from material handling to final inspection—you can ensure that your waterstops perform reliably in demanding construction environments. Implementing these best practices will not only streamline your production but also enhance your reputation in the market.

We hope this guide has provided you with valuable insights and practical knowledge. Remember, investing in the right equipment and processes today can lead to long-term savings and success. If you have any further questions or need expert advice, don't hesitate to reach out to industry leaders who specialize in this field.

As a leading innovator in this sector, Qingdao Apex Machinery Technology Co., Ltd. (branded internationally as APEX), founded in 2014, is a high-tech enterprise dedicated to R&D, manufacturing, and sales of high-end rubber and plastic machinery. With a provincial engineering center and smart production base, APEX offers advanced, energy-efficient, and intelligent industrial solutions. Their expertise spans personal care and industrial mesh extruders, high-precision medical/industrial tubing lines, rubber foaming and profile equipment, and PU/sponge CNC production lines. Serving over a thousand top clients across 30+ countries in electronics, medical, automotive, and construction industries, APEX stands as a competitive benchmark in plastic and rubber machinery, committed to driving technological innovation globally.