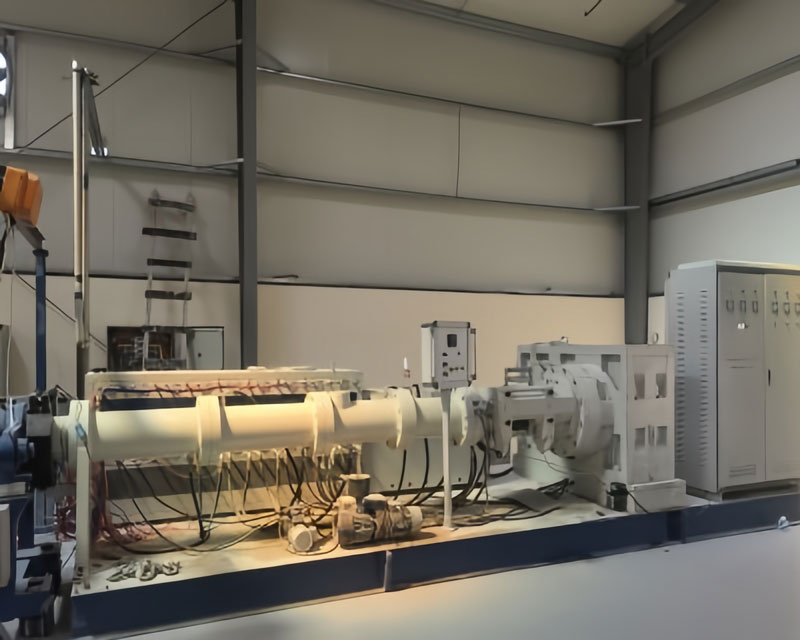

Rubber Extruder

I. Product Description

A rubber extruder is equipment used to process rubber into various shapes, mainly for producing rubber products. It heats raw rubber and forces it through a feed port, then shapes it via an extrusion head to form different rubber products like rubber tubes, sheets, and rings.

Typically composed of feeding, heating, extrusion, cooling, cutting, and control systems, the process involves rubber entering the heating system for pre-treatment, then being extruded into molds in the extrusion system. After cooling, it is cut into final products, with the control system monitoring the entire process for quality and efficiency.

Rubber extruders are crucial in rubber product manufacturing, enabling efficient production of diverse shapes to boost productivity and quality. They are widely used in rubber products, automotive, construction, electronics, and more.

With industry advancements, rubber extruders continuously innovate. Modern versions employ advanced control and automation for remote monitoring and smart production, enhancing efficiency and quality. Energy conservation and environmental protection are key focuses, reducing consumption and pollution.

II. Equipment Advantages (Core Selling Points)

Turnkey service: Equipment + specialized formulas + process technology + after-sales support

High efficiency: High automation increases productivity by over 30%

Precise control: Advanced PLC system ensures stable product quality

Energy-saving: Optimized design saves 15-20% energy vs. traditional models

Easy operation: User-friendly interface, simple staff training

Convenient maintenance: Modular design, easy replacement of key parts

Strong adaptability: Processes various rubber materials for diverse needs

III. Technical Parameters Table

| Parameter Name | Parameter Value | Unit | Remarks |

| Model | XJS-65 | - | Standard model |

| Screw Diameter | 65 | mm | Customizable as needed |

| L/D Ratio | 20:1 | - | Optimized plasticizing |

| Production Capacity | 80-150 | kg/h | Depends on material and product |

| Main Motor Power | 37 | kW | Frequency control |

| Heating Power | 18 | kW | Zone control |

| Heating Zones | 5 | sections | 4 barrel + 1 head |

| Temperature Control Accuracy | ±1 | ℃ | PID smart control |

| Cooling Method | Air/Water Cooling | - | Optional configuration |

| Dimensions | 4500×1200×1800 | mm | L×W×H |

| Weight | Approx. 3500 | kg | Net weight |

IV. Formula Table

| Material Name | Ratio(%) | Function | Remarks |

| Natural Rubber | 40-60 | Base Material | Adjustable per product requirements |

| Synthetic Rubber | 20-40 | Base Material | SBR, BR, etc. |

| Carbon Black | 25-50 | Reinforcing Agent | Enhances strength and wear resistance |

| Plasticizer | 5-15 | Softener | Improves processing |

| Vulcanizing Agent | 1-3 | Crosslinker | Sulfur or other systems |

| Accelerator | 0.5-2 | Speeds Vulcanization | Multiple accelerators combined |

| Anti-aging Agent | 1-3 | Anti-aging | Extends service life |

| Filler | 10-30 | Cost Reduction/Performance | Calcium carbonate, talc, etc. |

| Other Additives | 1-5 | Special Functions | Colorants, flame retardants, etc. |

Note: Above is a general formula reference; specific formulas are customized per client product requirements.

V. Equipment List

| No. | Equipment Name | Specification Model | Quantity | Remarks |

| 1 | Main Unit | XJS-65 | 1 unit | Includes motor, gearbox |

| 2 | Control System | PLC-2000 | 1 set | Siemens PLC, touch screen |

| 3 | Heating System | JH-5 | 1 set | 5 zones, ceramic heaters |

| 4 | Cooling System | LQ-65 | 1 set | Air/water cooling optional |

| 5 | Feeding Device | WL-1 | 1 set | Forced feed with hopper |

| 6 | Head Die | Custom | 1 set | Customized per product |

| 7 | Cutting System | QG-100 | 1 set | Auto length cutting |

| 8 | Auxiliary System | FJ-1 | 1 set | Haul-off, winding, etc. |

| 9 | Tools & Spares | Standard Pack | 1 set | Installation tools & wear parts |

VI. Process Flow Chart

1. Raw Material Prep → Mixing → Compound Preparation

2. Feeding System → Material Input → Forced Feed

3. Heating System → Preheating → Plasticizing

4. Extrusion System → Screw Extrusion → Mold Shaping

5. Cooling System → Water/Air Cooling → Setting

6. Haul-off System → Constant Pull → Shape Maintenance

7. Cutting System → Length Cutting → Product Forming

8. Collection & Packing → Inspection → Storage

Process Note: Central control monitors the entire process for precise parameters and reliable quality.

VII. Application Fields

Rubber Products: Hoses, belts, sheets, seals, etc.

Automotive: Seals, hoses, dampers, tire parts

Construction: Sealants, waterproofing, soundproofing

Electronics: Cable insulation, component seals

Home Appliances: Seals, vibration pads

Medical Devices: Tubes, seals

Sports Goods: Equipment parts, accessories

VIII. About APEX

Headquarters: Qingdao, Shandong, China, Established 2014

Market Distribution: Domestic: 35%, North America: 9%, South Asia: 7%, South America: 7%, Eastern Europe: 6%, Middle East: 5%, Other: 31%

Scale: 3 plants, 2 industrial parks, 100+ employees, 10+ years expertise

Service Commitment:

Quality first, customer supreme

Turnkey projects, full technical support

OEM/ODM customization supported

Permanent online video support

Quick response, solutions within 24 hours