XPE/IXPE Foam Material Production Line

I. Product Description

XPE/IXPE foam material production line is a continuous or batch production line specifically used for producing polyethylene (PE) foam materials. Through chemical cross-linking (XPE) or electron beam/γ-ray radiation cross-linking (IXPE) processes, the polyethylene material forms a stable cell structure during foaming, thereby obtaining excellent physical properties. Purpose: Used to produce XPE (chemically cross-linked polyethylene foam) and IXPE (electron radiation cross-linked polyethylene foam), featuring lightweight, thermal insulation, heat insulation, sound insulation, cushioning, moisture resistance, corrosion resistance, and easy processing. Widely used in automotive, construction, home appliances, medical, packaging, toys, sports goods, and other fields.

Main product types: XPE (chemically cross-linked polyethylene foam): Cross-linking achieved through chemical cross-linking agents, suitable for conventional foam products. IXPE (electron radiation/γ-ray cross-linked polyethylene foam): Cross-linking achieved through electron accelerator or γ-ray irradiation, with finer cells and superior performance, used in high-end fields.

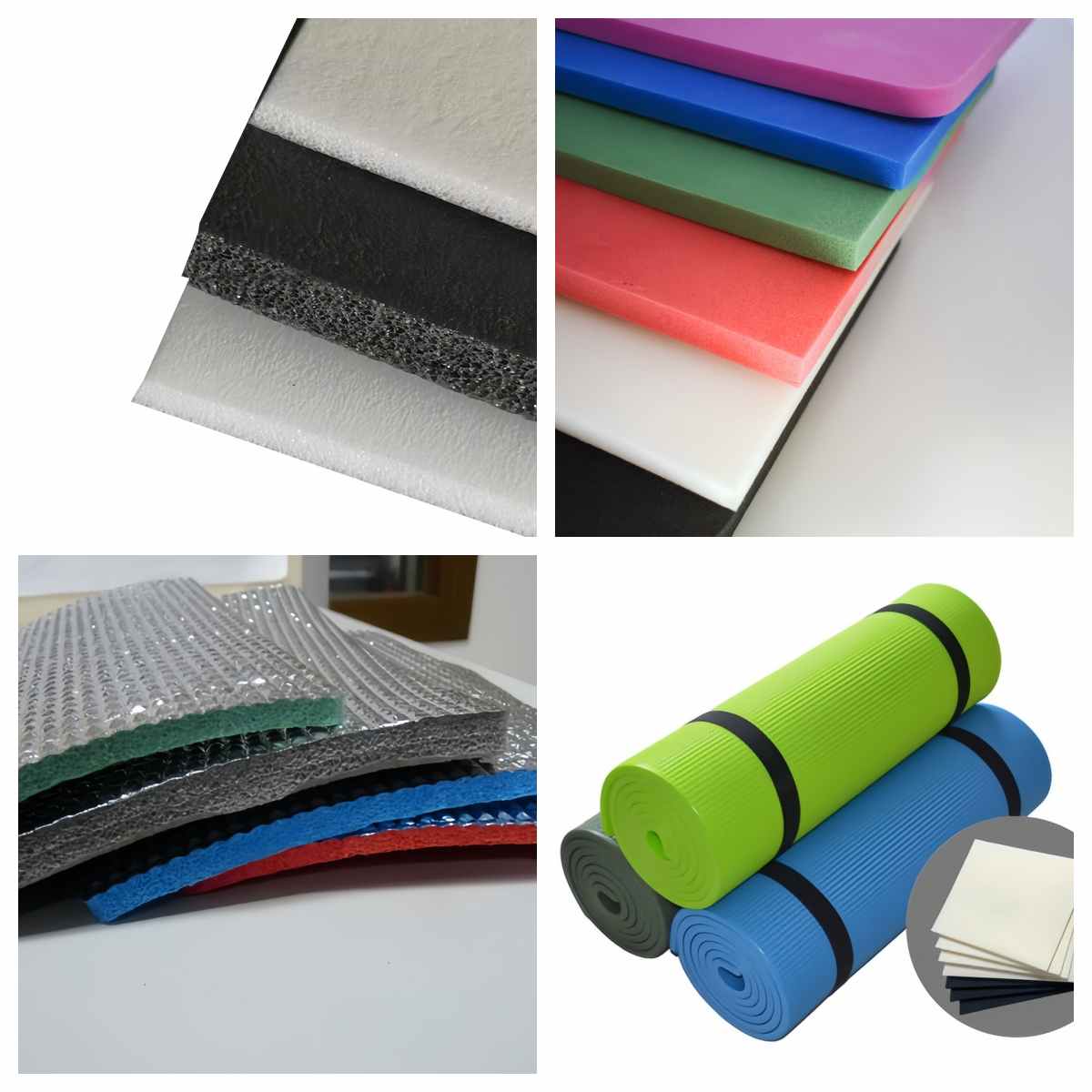

Typical product application forms: Foam sheets, rolls, profiles, molded products (such as automotive floor mats, sound insulation cotton, thermal insulation layers, protective pads, etc.)

Core advantages: Lightweight, thermal insulation, sound insulation, cushioning, moisture resistance, easy processing, environmentally friendly (recyclable)

II. Equipment Advantages (Core Selling Points)

Versatile machine: Supports both mainstream processes: XPE (chemical cross-linking) and IXPE (radiation cross-linking)

Flexible cross-linking methods: Chemical cross-linking (adding cross-linking agents) or physical radiation cross-linking (electron beam/γ-ray), meeting different performance requirements

Controllable foaming ratio: Can adjust density and cell structure as needed (wide density range, fine and uniform cells)

Continuous production: Supports continuous extrusion, foaming, cooling, and winding, high efficiency, suitable for large-scale mass production

Strong material compatibility: Suitable for LDPE, HDPE, LLDPE and other base resins, can add color masterbatch, flame retardants, antistatic agents and other functional additives

High degree of automation: Supports automatic temperature control, speed control, online monitoring, winding, etc.

Energy saving and environmental protection: Lower energy consumption compared to traditional batch foaming, scrap can be recycled

Provides turnkey projects: Equipment + process formulation + technical training + after-sales support

Customizable: Output, width, thickness, automation level, voltage, etc. can be customized as needed

III. Technical Parameter Table

The following are the main technical parameters of a typical XPE/IXPE foam material production line

| Item | Parameter / Description | Unit | Typical Value / Range |

| Foam Type | - | - | XPE (Chemical Cross-linking) / IXPE (Radiation Cross-linking) |

| Production Line Type | - | - | Continuous Extrusion Foaming Line (Single/Twin Screw) |

| Max Production Width | - | mm | 600 ~ 2000 |

| Foam Thickness Range | - | mm | 1 ~ 20 (Customizable for thicker) |

| Foam Density Range | - | kg/m³ | 15 ~ 300 (Adjustable) |

| Line Speed | - | m/min | 3 ~ 25 |

| Cross-linking Method | - | - | Chemical Cross-linking (XPE) / Electron Beam/γ-ray Cross-linking (IXPE) |

| Total Power | Entire Line | kW | 80 ~ 300 |

| Control Method | - | - | PLC Automatic / Semi-automatic / Manual |

IV. Formulation Table (Common Materials for XPE/IXPE Foam)

The following are common resin and additive systems for XPE/IXPE foam

| Material Type | Common Resins | Function and Characteristics |

| Base Resin | LDPE (Low-Density Polyethylene) | Soft, large cells, commonly used for XPE |

| Base Resin | HDPE (High-Density Polyethylene) | High strength, fine cells, commonly used for IXPE or structural parts |

| Base Resin | LLDPE (Linear Low-Density Polyethylene) | Combines flexibility and strength, uniform cells, strong versatility |

| Cross-linking (XPE) | DCP (Dicumyl Peroxide) | Chemical cross-linking agent, achieves cross-linking through thermal decomposition |

| Radiation Cross-linking (IXPE) | - | Cross-linking achieved through electron accelerator (10~30MeV) or γ-ray irradiation, no chemical additives needed |

| Additives | Foaming Agent (AC, Azo type, etc.) | Generates gas to form cells |

| Additives | Nucleating Agent, Flame Retardant, Antistatic Agent, Color Masterbatch, etc. | Added as needed to enhance functionality and appearance |

V. Equipment List (Main Components)

1. Extruder (Single Screw / Twin Screw, for PE resin melting and plasticizing)

2. Foaming Die Head (Specially designed, controls cell structure and foaming ratio)

3. Chemical Cross-linking System (e.g., adding DCP and other cross-linking agents, XPE process)

4. Radiation Cross-linking System (Electron Accelerator/γ-ray Source, IXPE process, optional)

5. Cooling and Setting Device (Water Cooling / Air Cooling, controls cell stability)

6. Haul-off and Winding Machine (Continuous winding into rolls or sheets)

7. Online Thickness / Width / Temperature Control System (Optional, enhances automation)

8. Control System (PLC / Touch Screen / Automatic Control)

VI. Process Flow Diagram (Brief Description)

Typical process flow for XPE/IXPE foam material is as follows:

Batching and Mixing: Mix polyethylene resin with foaming agent, cross-linking agent (XPE), additives, etc., uniformly according to the formulation ratio

Melting and Plasticizing: Heat and melt the mixture through the extruder to form a uniform melt

Foaming and Molding: The melt passes through a specially designed foaming die head, releasing gas under high temperature and pressure to form cells, completing foaming

Cross-linking (Key Step):

XPE: Achieve intermolecular cross-linking through the decomposition of chemical cross-linking agents (e.g., DCP) during heating

IXPE: Achieve cross-linking of polyethylene molecular chains through electron accelerator or γ-ray irradiation (no chemical additives needed)

Cooling and Setting: Rapidly cool the foam material through water or air cooling to fix the cell structure

Haul-off and Winding: Continuously haul off and wind into rolls or cut into sheets according to size

Inspection / Packaging: Check thickness, density, appearance, then package and store

VII. Application Fields

Automotive: Car floor mats, sound insulation cotton, thermal insulation layers, anti-collision pads, interior trim foam layers

Construction: Wall insulation boards, roof insulation materials, floor sound insulation pads, pipe insulation

Home Appliances: Refrigerator insulation layers, washing machine shock absorption pads, air conditioner sound insulation materials, microwave oven anti-scald pads

Medical: Medical shockproof pads, cleaning anti-slip pads, sterilization packaging cushioning materials

Packaging: Electronic product cushioning packaging, precision instrument shockproof packaging, express delivery anti-collision liners

Toys: Children's crawling mats, soft toy pads, safety protective pads

Sports: Sports floor mats, fitness mats, anti-slip mats, ball inner bladder cushioning layers

VIII. About Us

Headquarters: Qingdao, Shandong, China, established in 2014

Market: Domestic 35%, North America 9%, South Asia/South America/Eastern Europe/Middle East each account for 7%~5%

Scale: 3 branch factories, 2 major industrial parks, 100+ employees, 10+ years of professional experience

Service: Quality first, turnkey projects, full-process technical support