Plastic Makeup Brush Filament Extrusion Production Line

I. Product Description

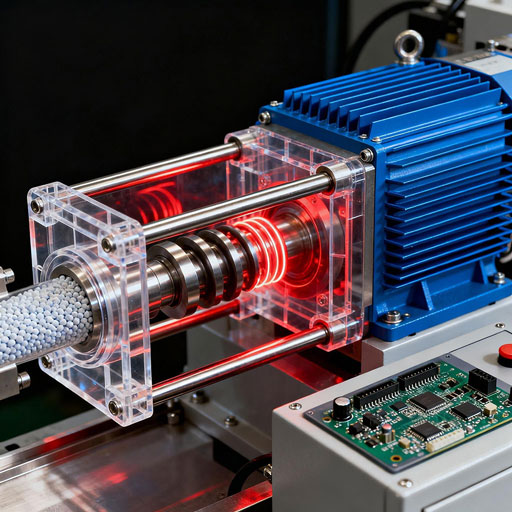

The plastic makeup brush filament extrusion production line is a professional extrusion system specifically designed for producing high-quality plastic monofilaments for makeup brushes. Through precision molds and temperature control, this line melts and plasticizes plastic raw materials (such as PP, PA, PET, etc.), uniformly extrudes them through a high-precision T-die, and then undergoes cooling, drawing, winding, and other processes to produce soft, fine, highly elastic, easy-to-clean, safe, and environmentally friendly makeup brush filaments. These are widely used in the manufacturing of makeup tools like foundation brushes, eyeshadow brushes, blush brushes, and eyebrow brushes.

II. Equipment Advantages (Core Selling Points)

We provide a true "turnkey" overall solution, covering equipment, formulations, processes, and after-sales support, ensuring a worry-free start to production:

• Complete Equipment: Includes raw material handling, extruder, die, cooling system, drawing, winding, etc.

• Specialized Formulations: Provide optimized formulations for PP/PA/PET, etc., ensuring filament softness, elasticity, and safety.

• Mature Process: 10+ years of experience in makeup brush filament production, precise control of filament diameter, softness, and strength.

• Turnkey Service: Equipment + Formulations + Process Technology + After-sales Support, one-stop implementation.

• Support for OEM/ODM Customization: Can customize brand, packaging, and specifications according to customer needs.

• Permanent Online Technical Support: Remote video guidance, process optimization, problem response.

III. Technical Parameter Table

| Item | Parameter |

| Applicable Raw Materials | PP, PA (Nylon), PET, PE, etc. |

| Extruder Type | Single Screw (Precision Type) |

| Screw Diameter | Φ30~Φ75 mm |

| Die Type | T-Die (Multi-hole, 10~100 holes) |

| Filament Diameter Range | 0.05~0.25 mm (50~250 microns) |

| Number of Die Holes | 10~100 holes (depending on capacity) |

| Line Speed | 3~20 m/min |

| Control System | PLC + Temperature Control + Drawing Control |

| Cooling Method | Water Bath Cooling (Stable Shaping) |

| Winding Method | Automatic/Semi-automatic Winding, Coiling or Spool |

IV. Formulation Table (Example: PP-based Makeup Brush Filament)

| Component | Proportion (%) | Function |

| PP / PA / PET | 85~93% | Main material, determines filament hardness and elasticity |

| Softening Modifier | 3~8% | Enhances brush filament softness and skin-friendly feel |

| Color Masterbatch | 1~3% | Provides various colors, supports customization |

| Lubricant | 0.2~1% | Improves processability, prevents melt adhesion |

| Antistatic Agent | 0.3~1% | Reduces dust accumulation and static electricity on filaments |

V. Equipment List (Typical Configuration)

| No. | Equipment/System | Function |

| 1 | Raw Material Mixing/Drying System | Ensures raw material cleanliness and dryness |

| 2 | Single Screw Extruder | Melts and plasticizes plastic raw materials |

| 3 | T-Die | Multi-hole extrusion of makeup brush filaments |

| 4 | Cooling Water Bath | Uniform cooling, stabilizes filament shape |

| 5 | Drawing Device | Adjusts filament strength and softness |

| 6 | Winding Machine | Winds the formed filaments for subsequent processing |

| 7 | Electrical Control System | Precise control of temperature and speed |

VI. Process Flow Chart

[Raw Material Mixing] → [Drying] → [Extruder Melting] → [T-Die Extrusion] → [Cooling Water Bath Shaping]→ [Drawing Device] → [Winding Machine] → [Post-processing/Cutting/Implantation into Brush Head]

VII. Application Fields

• Makeup Brush Manufacturing (Foundation Brushes, Eyeshadow Brushes, Eyebrow Brushes, Blush Brushes, etc.)

• Cosmetics Brands, OEM/ODM Makeup Tool Manufacturers

• High-end, Portable, Eco-friendly Makeup Brush Products

• Export Markets (Europe & America, Japan & South Korea, Middle East, etc.)

VIII. About Us

Headquarters: Shandong, China

Established: 2014 (Over 10 years focused on plastic extrusion equipment)

Market Distribution: Domestic: 35%, North America: 9%, South Asia/South America/Eastern Europe/Middle East: 7%~5% each

Company Scale: 3 branch factories, 2 major industrial parks, 100+ employees

Service Principle: Quality First, Turnkey Projects, Full-process Technical Support, Support for OEM/ODM Customization, Permanent Online Video Technical Support