PPR / PP Cold and Hot Water Pipe Plastic Extrusion Production Line

I. Product Description

PPR (Random Copolymer Polypropylene) / PP (Polypropylene) cold and hot water pipes are plastic pipes used in building water supply, heating, underfloor heating, and other fields. They feature high temperature resistance (long-term use temperature ≤ 95°C), pressure resistance, corrosion resistance, hygiene and non-toxicity, long service life (50 years+), and easy installation, making them an ideal replacement for traditional metal pipes. This production line is specifically designed for producing PPR/PP cold and hot water pipes in different specifications such as DN16~DN110, meeting national standards and engineering requirements.

II. Equipment Advantages (Core Selling Points)

Optimized design specifically for PPR/PP materials, ensuring stable melt, smooth inner and outer pipe walls, and precise dimensions

Supports high-speed extrusion, high production efficiency, suitable for large-scale production

Modular design, supports customization for different pipe diameters (DN16-DN110) and wall thicknesses

Equipped with complete downstream processes: vacuum sizing, spray/air cooling, traction, cutting, etc.

Automated control: closed-loop control of temperature, speed, and pressure ensures stable quality

Provides turnkey services: Extrusion line equipment (Single/Twin Screw) • PPR/PP specific formulations (Raw material + Additives) • Process technical guidance (Formulation, temperature, speed, etc.) • After-sales support and operation training • Supports OEM production / Custom branding • Permanent online video technical support

III. Technical Parameter Table

| Item | Parameter / Description | Typical Value / Range |

| Applicable Material | PPR (Random Copolymer Polypropylene), PP (Polypropylene) | Pipe Grade Resin |

| Production Line Type | Plastic Extrusion Line (Single/Twin Screw) | Suitable for Pipe Diameter DN16 ~ DN110 |

| Pipe Diameter Range | Nominal Diameter | DN16 – DN110 mm |

| Pipe Wall Thickness | mm | 1.0 ~ 6.0 (Depending on specification) |

| Extruder | Type | Single Screw / Parallel Twin Screw |

| Screw Diameter | mm | φ45 / φ65 / φ90 etc. |

| Max Output | kg/h | 30 ~ 120 (Depending on model) |

| Line Speed | m/min | 0.5 ~ 6.0 |

| Sizing Method | - | Vacuum Sizing + Spray/Air Cooling |

| Control System | - | PLC / Touch Screen / Automatic Temperature Control |

| Customization Capability | - | Supports multi-specification switching, brand LOGO, OEM |

IV. Formulation Table (Common PPR/PP Pipe Systems)

| Material Type | Common Materials | Function and Role |

| Main Material | PPR (Random Copolymer Polypropylene) | Base material, provides heat resistance, pressure resistance, hygiene performance |

| Additives | Antioxidants, Light Stabilizers | Enhance aging resistance, UV resistance |

| Color Masterbatch | PP Special Color Masterbatch | Imparts pipe color (Commonly green, white, gray) |

| Processing Aids | Lubricants, Dispersants | Improve melt flowability, processing stability |

V. Equipment List

| No. | Equipment Name | Function |

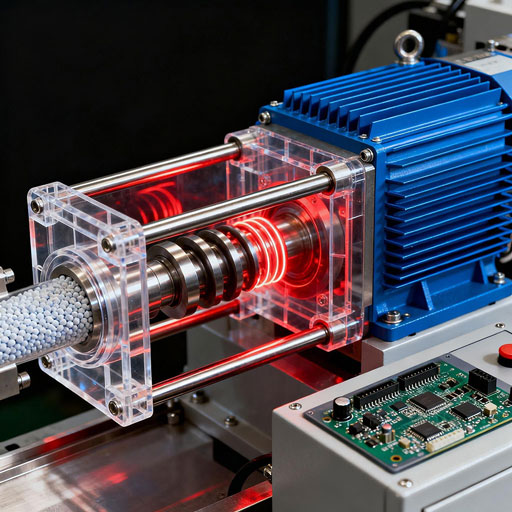

| 1 | Single/Twin Screw Extruder | Material melting, plasticizing, extrusion |

| 2 | Die (Pipe Extrusion Head) | Determines pipe inner diameter and wall thickness |

| 3 | Vacuum Sizing Tank | Maintains stable pipe outer diameter, preliminary cooling and shaping |

| 4 | Cooling Tank / Spray System | Further cooling and shaping |

| 5 | Haul-off Unit | Evenly pulls the pipe, controls speed |

| 6 | Cutter | Automatically cuts to set length |

| 7 | Turnover Rack / Stacker | Automatically collects finished pipes |

| 8 | Control System (PLC) | Automatic control of temperature, speed, pressure |

VI. Process Flow Chart (Text Version)

Raw Material Preparation: PPR/PP pellets dried

Mixing (Optional): Add color masterbatch, additives, mix uniformly

Extrusion: Melted and plasticized through extruder, extruded into tubular shape via die

Vacuum Sizing: Pipe passes through vacuum tank, outer diameter stabilized and preliminarily cooled

Cooling: Water cooling or spray cooling to fully solidify the pipe

Haul-off: Evenly pulls the pipe, maintaining consistent speed

Cutting: Automatically cuts to set length

Collection: Finished pipes stacked or packaged

VII. Application Fields

Building Water Supply: Cold and hot water piping systems

Heating Systems: Underfloor heating, radiator connection pipes

Engineering Projects: Water supply networks for schools, hospitals, residential communities

High-Temperature Water Transport: Long-term withstands 70~95°C hot water

Industrial Piping: Fluid transport requiring high hygiene and corrosion resistance

VIII. About Us

Headquarters: Shandong, China

Established: 2014

Market Distribution: Domestic 35%, North America 9%, South Asia/South America/Eastern Europe/Middle East 7%~5% each

Company Scale: 3 branch factories, 2 major industrial parks, 100+ employees, 10+ years professional experience

Service Philosophy: Quality first, turnkey projects, full-process technical support. Supports OEM customization, permanent online video technical support.