CNC Sponge Continuous Production Line - Automatic Horizontal Foaming Machine for Mattress Manufacturing

I. Product Description

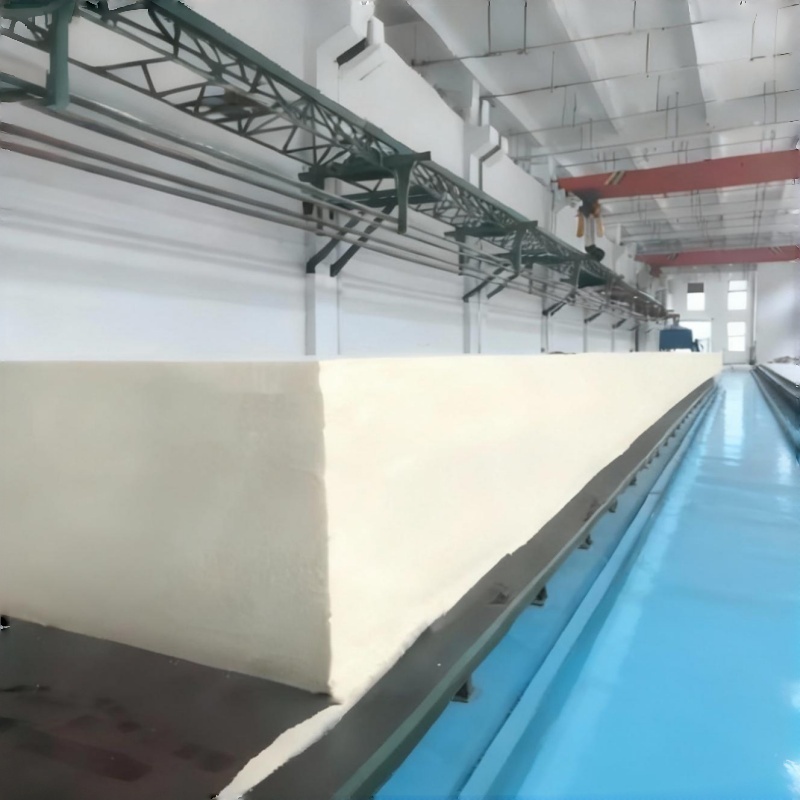

The CNC Sponge Continuous Production Line is a fully automated equipment system specifically designed for producing soft foam materials such as polyurethane soft foam (PU Foam) mattresses, sofa cushions, seat sponges, and automotive interior sponges. The core equipment is the automatic horizontal foaming machine, which uses a continuous pouring + horizontal foaming process. Polyol and Isocyanate are mixed in precise proportions and then continuously foamed and shaped on a conveyor belt, forming sponge blocks with uniform density, excellent elasticity, and controllable thickness. These are then cut, trimmed, and packaged to produce mattresses, cushions, and other products.

This production line is suitable for mattress factories, furniture factories, automotive seat factories, and soft home furnishing manufacturers. It offers advantages such as high capacity, high precision, intelligent control, and energy saving & environmental protection, making it the core equipment for modern sponge product production.

II. Equipment Advantages (Core Selling Points)

Adopts horizontal continuous foaming process, suitable for large-scale continuous production, high efficiency, large capacity

Precise metering and mixing system ensure stable A/B material ratio, uniform cell structure, controllable density

Fully automated control: PLC + Touch Screen + Temperature Control System, enabling stable unattended operation

Modular design supports continuous production of sponges with different densities, thicknesses, and widths

Equipped with automatic cutting, trimming, winding or stacking systems (expandable), realizing the entire process from foaming to final shaping

Provides turnkey service:

• Automatic Horizontal Foaming Machine Host • Specialized A/B Material Formulation for Sponge Foaming (Polyol + Isocyanate + Catalysts, etc.) • Process Technology (Ratio, Temperature, Speed, Density Control)

III. Technical Parameter Table

| Item | Parameter / Description | Typical Value / Range |

| Foaming Type | - | Polyurethane Soft Foam (PU Foam), Continuous Foaming |

| Machine Type | - | Automatic Horizontal Continuous Foaming Machine |

| Foaming Process | - | Horizontal Continuous Pouring Foaming |

| A/B Material Ratio | - | Typically 1:1 ~ 1:5 (Adjustable) |

| Mixing Pressure | Bar | 80 ~ 150 |

| Tank Capacity | L | 50 ~ 200L (A/B Material) |

| Production Line Speed | m/min | 0.5 ~ 3.0 (Adjustable based on density) |

| Foam Density | kg/m³ | 20 ~ 200 (Adjustable) |

| Control Method | - | PLC + Touch Screen + Temperature Control |

| Conveyor Belt Width | mm | 800 ~ 2000 (Customizable) |

| Operating Temperature | ℃ | Recommended Raw Material Temperature 20 ~ 25°C |

IV. Formulation Table (Polyurethane Sponge Foaming Material System)

| Material Type | Common Materials | Function & Role |

| Polyol (A Material) | Polyether Polyol | Forms the basic foam skeleton, affects softness, resilience |

| Isocyanate (B Material) | TDI / MDI | Reacts with polyol to form polyurethane network structure |

| Catalyst | Amine / Metal Salt | Controls foaming reaction rate and cell structure |

| Blowing Agent | Water / Cyclopentane (Physical Blowing Agent) | Generates gas, forms cells |

| Additives | Silicone Oil (Surfactant), Flame Retardant, Color Paste, etc. | Improves cell structure, flame retardancy, coloring, etc. |

V. Equipment List

| No. | Equipment Name | Function |

| 1 | Automatic Horizontal Foaming Machine Host | Continuous Mixing and Pouring Foaming |

| 2 | Mixing Head | High-speed mixing of A/B materials |

| 3 | Conveyor Belt System | Carries foam forward continuously for shaping |

| 4 | A/B Material Storage Tanks | Store raw materials, constant temperature control |

| 5 | Metering Pumps | Precisely deliver A/B materials |

| 6 | Temperature Control System | Controls raw material temperature |

| 7 | PLC Control System | Automated operation and parameter setting |

| 8 | Cutting / Trimming System (Optional) | Cuts to required shape |

VI. Process Flow Chart (Text Version)

Raw Material Preparation: Polyol, Isocyanate, and additives heated to 20~25°C according to formulation

Metering & Conveying: Precisely metered to mixing head via high-precision pumps at set ratio

Mixing & Foaming: High-speed mixing in mixing head, instant reaction and foaming

Continuous Pouring: Foaming material continuously poured onto moving conveyor belt

Foam Shaping: Foaming, expansion, and initial curing completed on conveyor belt

Subsequent Processing (Optional): Cutting, Trimming, Stacking, Packaging

VII. Application Fields

Mattress Manufacturing: Various soft/hard mattresses, memory foam, latex composite pads

Furniture: Sofa cushions, back cushions, mattress cores

Automotive: Seat sponges, headrests, interior soft foam

Home: Pillows, soft pads, sound insulation materials

Medical: Nursing pads, rehabilitation sponges

VIII. Energy Saving & Cost Reduction

The electrical control cabinets and motor systems procured by APEX achieve a comprehensive power saving rate of 5%-60% through integrated technologies such as variable frequency speed regulation, intelligent control, and efficient hardware design. The core energy-saving mechanisms are as follows:

1. Variable Frequency Speed Regulation: Dynamically matches load demand (Energy Saving Contribution: 10%-35%)

2. Intelligent Control System: Multi-dimensional optimization of energy efficiency (Energy Saving Contribution: 5%-15%)

3. Efficient Hardware Design: Reduces basic losses (Energy Saving Contribution: 3%-10%)

IX. About Us

Headquarters: Shandong, China

Established: 2014

Market Distribution: Domestic 35%, North America 9%, South Asia/South America/Eastern Europe/Middle East each 7%~5%

Enterprise Scale: 3 branch factories, 2 major industrial parks, 100+ employees, 10+ years professional experience

Service Philosophy: Quality first, turnkey projects, full-process technical support. Supports OEM customization, permanent online video technical support.