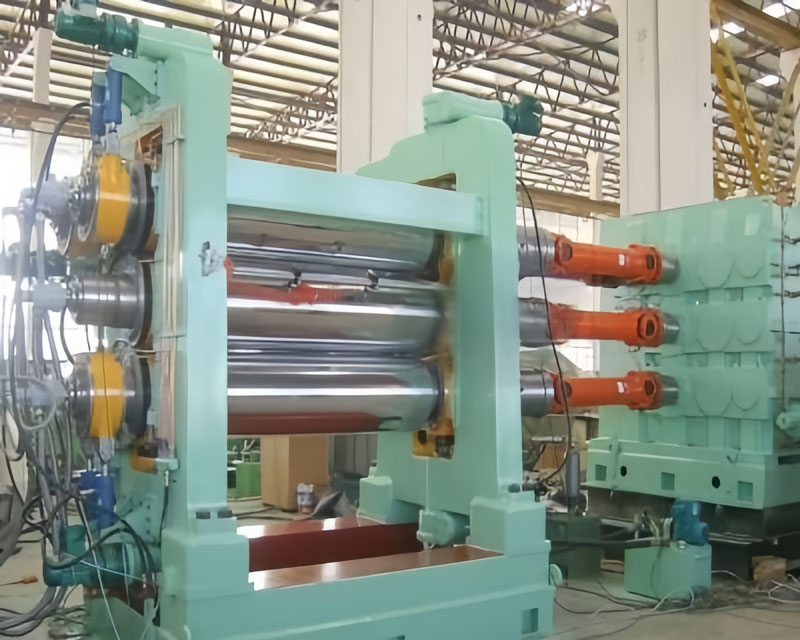

Four Roll Rubber Calender

High Precision · High Efficiency · Strong Stability · Flexible & Diverse

I. Product Description

The four-roll calender is a high-precision equipment used for plastic or rubber calendering processing. It utilizes four rollers (two upper and two lower) to uniformly and precisely press plastic or rubber material, forming products of the required size and thickness. Compared to a three-roll calender, the four-roll design provides more uniform pressure distribution and higher processing accuracy.

Working Principle: The four-roll calender drives four rollers to rotate simultaneously via a drive motor and reducer. The material is uniformly squeezed and extended in the gaps between the rollers. By precisely controlling roller speed, gap, and temperature, accurate control over product thickness, width, and surface quality can be achieved.

Main Components:

Four Rollers: Two upper and two lower rollers, typically made of high-strength alloy steel, with surfaces precision ground and chrome-plated.

Drive System: Includes motor, reducer, gearbox, etc., providing stable power.

Lubrication System: Ensures lubrication and heat dissipation during normal operation.

Temperature Control System: Precisely controls roller temperature to adapt to different material processing needs.

Adjustment Device: Used for precise adjustment of roller gap.

Electrical Control System: PLC control for automated operation.

II. Equipment Advantages (Core Selling Points)

High Efficiency: Efficiently processes plastic or rubber materials, improving production efficiency and reducing costs.

High Precision: Achieves precise processing of plastic or rubber materials by controlling roller speed and gap, ensuring accurate product dimensions and thickness.

Strong Flexibility: Can be adjusted and modified according to different needs, suitable for processing products of various thicknesses and widths.

Simple Operation: Relatively simple to operate, requiring only basic training, reducing labor costs.

Good Stability: Utilizes four rollers working simultaneously, offering high stability and ensuring smooth material running during processing.

Excellent Uniformity: The four-roll design ensures more uniform pressure distribution and higher product thickness consistency.

Turnkey Service Provided:

We provide comprehensive turnkey project services from equipment design, manufacturing, installation, commissioning to personnel training, ensuring customers can quickly start production and achieve expected results. This includes process formula optimization, production line layout design, operator training, and full-range support.

Operation Specifications:

Before operation, carefully inspect all components of the four-roll calender to ensure safety and stability.

During operation, select appropriate roller spacing and speed based on material type and specifications to ensure smooth processing.

During processing, regularly check the working status of the calender, keep the equipment clean, perform timely maintenance and upkeep to extend service life.

After use, promptly turn off the power and air supply, clean the work area, ensuring equipment and personnel safety.

III. Technical Parameter Table

IV. Formula Table

| Raw Material Name | PVC Transparent Film Formula (phr) | Rubber Sheet Formula (phr) | Waterproof Membrane Formula (phr) |

| PVC Resin (SG-5) | 100 | - | - |

| Natural Rubber (NR) | - | 70 | 50 |

| Styrene Butadiene Rubber (SBR) | - | 30 | 30 |

| EPDM Rubber | - | - | 20 |

| Plasticizer (DOP) | 45 | - | 15 |

| Stabilizer | 3.5 | - | - |

| Calcium Carbonate | 15 | 30 | 40 |

| Carbon Black | - | 45 | 35 |

| Titanium Dioxide | 2 | - | - |

| Zinc Oxide | - | 5 | 4 |

| Stearic Acid | 0.5 | 2 | 1.5 |

| Anti-aging Agent | - | 2.5 | 2.5 |

| Accelerator | - | 1.2 | 1 |

| Sulfur | - | 2 | 1.8 |

V. Equipment List

| No. | Equipment Name | Specification Model | Qty | Remarks |

| 1 | Main Motor | Configured per model | 1 unit | Variable frequency speed control, IE3 efficiency |

| 2 | Reducer | Hardened gear reduction | 1 unit | Transmission efficiency ≥96% |

| 3 | Four Rollers | Alloy steel forging | 4 pcs | Hard chrome plated surface, mirror polished |

| 4 | Roller Bearings | Double row roller bearings | 8 sets | High load capacity, long life |

| 5 | Lubrication System | Centralized lubrication | 1 set | Automatic timed定量 lubrication |

| 6 | Temperature Control System | PID intelligent control | 1 set | Segmented control, accuracy ±1℃ |

| 7 | Adjustment Device | Electric/Hydraulic adjustment | 1 set | Digital display, accuracy 0.005mm |

| 8 | Electrical Control System | PLC+Touch Screen | 1 set | Siemens/Mitsubishi brand, networkable |

| 9 | Frame | Steel plate welding | 1 set | Stress relief treatment, high strength |

| 10 | Safety Protection Device | Complies with CE standard | 1 set | Emergency stop button, safety interlock |

| 11 | Auxiliary System | Optional | 1 set | Includes stripping, cooling, winding, etc. |

VI. Process Flow Chart

Four Roll Calender Process Flow

Raw Material Prep → Batching & Mixing → Plasticating/Mixing → Feeding & Conveying → Four-Roll Calendering → Stripping & Shaping → Cooling & Setting → Traction → Winding → Inspection → Packaging & Storage

Note: Actual flow chart should include more detailed equipment connections and process parameters.

VII. Application Fields

Plastic Products: PVC film, sheet, synthetic leather, floor covering, transparent sheet, etc.

Rubber Products: Rubber plate, rubber sheet, conveyor belt cover rubber, sealing materials, etc.

Building Materials: Waterproof membrane, decorative materials, soundproofing materials, wallpaper, etc.

Packaging Materials: Packaging film, composite packaging materials, food packaging, etc.

Other Fields: Automotive interiors, medical product substrates, electronic component packaging materials, etc.

VIII. About APEX

Headquarters: Shandong, China, established in 2014

Scale: 3 branch factories, 2 major industrial parks, 100+ employees, 10+ years professional experience

Market Distribution:Domestic: 35%,North America: 9%,South Asia/South America/Eastern Europe/Middle East: 7%~5% each

Service Commitment:Quality First, Turnkey Projects,Full-process Technical Support,OEM Customization Supported,Permanent Online Video Support,24/7 After-sales Response,Fast Spare Parts Supply