PVC Garden Hose Manufacturing Machine--PVC Water and Air Fiber Hose Extrusion Line

I. Product Description

This production line is specially used for producing PVC garden hoses, water/air hoses, fiber-reinforced hoses, suitable for agricultural irrigation, garden watering, household water supply, industrial low-pressure gas/liquid transportation, etc. The product has advantages such as good flexibility, strong weather resistance, UV resistance, smooth inner wall, customizable colors and printing, etc., and is a commonly used flexible connection pipe in civil and industrial fields.

Supports production of ordinary smooth pipes, fiber-reinforced pipes, printed pipes, multi-color pipes, wide pipe diameter range, diverse structures, is the mainstream production solution for PVC hose products.

II. Equipment Advantages (Core Selling Points)

Specially optimized for PVC hose, stable extrusion, smooth surface, precise dimensions

Supports fiber reinforcement (e.g., polyester thread, fiber cloth), improves pressure and tensile performance

Can produce single/double layer pipes, supports printing, colors, LOGO customization

Modular design, adapts to wide pipe diameter range (Φ6mm ~ Φ50mm or larger)

Equipped with cooling water tank, traction machine, winding machine, achieves continuous automated production

Provides turnkey service: PVC hose extrusion equipment (single/twin screw) • PVC special formula and additives • Process technology (temperature, speed, reinforcement structure, etc.) • After-sales support and operation training • Supports OEM production / custom branding • Permanent online video technical support

III. Technical Parameter Table

| Item | Parameter / Description | Typical Value / Range |

| Applicable Material | PVC (Flexible) | Universal PVC resin, can add fiber |

| Production Line Type | PVC Hose Extrusion Line | Single layer/Fiber reinforced/Printed |

| Pipe Diameter Range | Outer Diameter | Φ6 ~ Φ50 mm (Customizable) |

| Wall Thickness | mm | 0.2 ~ 2.0 |

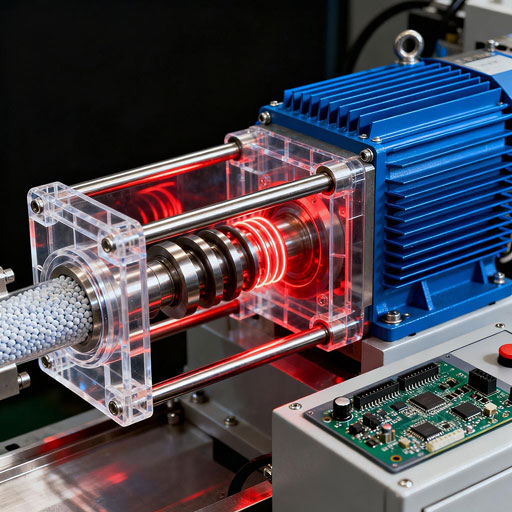

| Extruder | Type | Single Screw / Mini Twin Screw |

| Screw Diameter | mm | φ45 / φ50 / φ65 |

| Output | kg/h | 3 ~ 20 |

| Line Speed | m/min | 5 ~ 30 |

| Cooling Method | - | Water Tank Cooling / Air Cooling |

| Traction Method | - | Crawler Type / Roller Traction |

| Winding Method | - | Automatic Winding Machine |

| Control Method | - | PLC / Temperature Control / Speed Control |

IV. Formula Table (PVC Hose Material System)

| Material Type | Common Materials | Function and Role |

| Main Material | PVC (Polyvinyl Chloride, Flexible) | Base material, provides flexibility |

| Plasticizer | DOP / DOTP / Eco-friendly Type | Enhances flexibility and processability |

| Stabilizer | Calcium-Zinc Stabilizer / Organotin | Heat stability, light stability, eco-friendly |

| Lubricant | Internal/External Lubricant | Improves fluidity and surface gloss |

| Reinforcement Material (Optional) | Polyester Thread / Fiber Cloth | Improves pressure and tensile resistance |

| Colorant/Masterbatch (Optional) | PVC Special | Custom colors, identification |

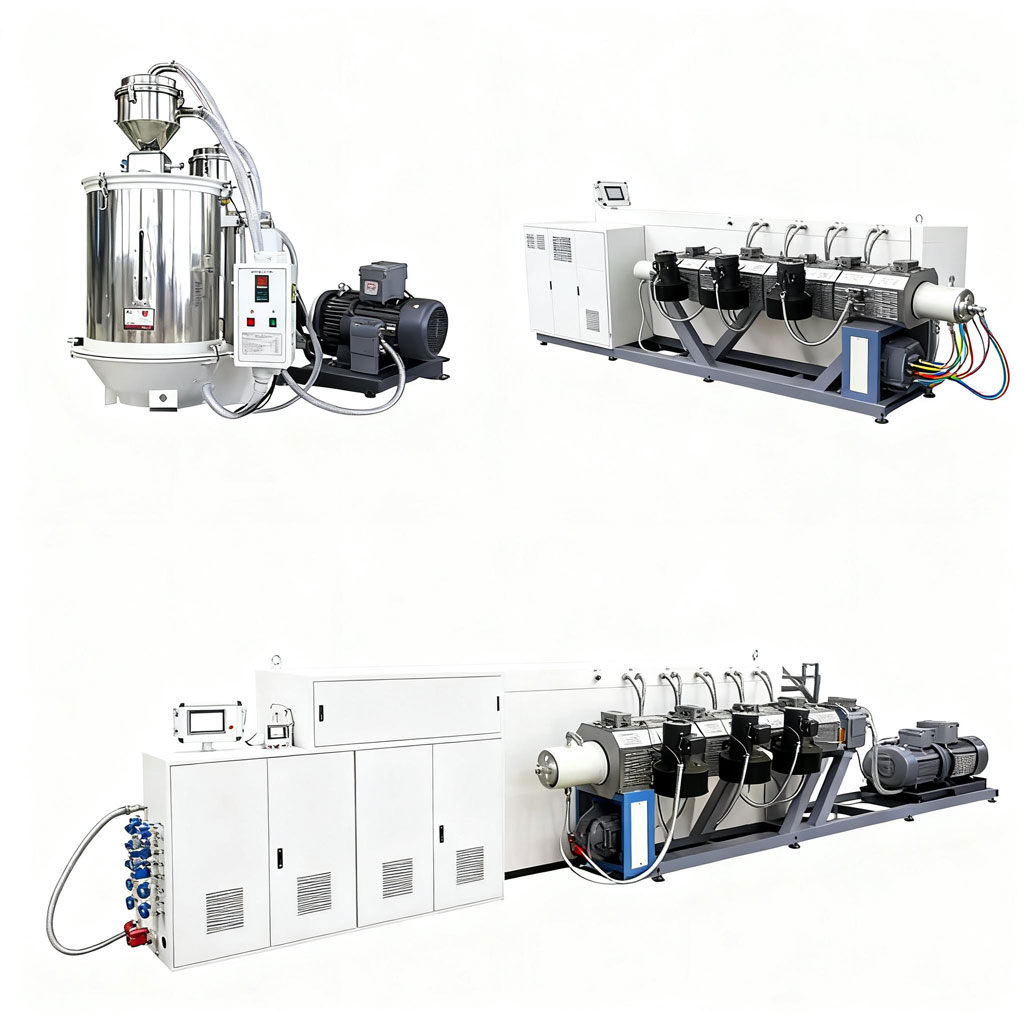

V. Equipment List

| No. | Equipment Name | Function |

| 1 | PVC Extruder (Single/Twin Screw) | PVC melting, plasticizing, extrusion |

| 2 | Mold (Hose Die Head) | Controls pipe inner diameter and wall thickness |

| 3 | Cooling Water Tank / Air Cooling | Cooling and shaping |

| 4 | Traction Machine | Evenly pulls the hose |

| 5 | Winding Machine | Automatically winds into coils |

| 6 | Fiber Reinforcement Device (Optional) | Adds fiber reinforcement layer |

| 7 | Control System | Temperature / Speed / Tension Control |

VI. Process Flow Chart (Text Version)

Raw Material Preparation: PVC resin + additives + reinforcement material (optional) mixed according to formula

Mixing (Optional): Add plasticizer, stabilizer, colorant, mix evenly

Extrusion: Melts through extruder, extruded into hose via die

Cooling: Water tank or air cooling, solidifies the hose

Traction: Evenly pulls, maintains consistent speed

Winding: Automatically coils into reels for transportation

VII. Application Fields

Gardening: Garden watering, sprinkler hoses

Household: Tap water, cleaning water pipes

Agriculture: Irrigation, greenhouse water supply

Industry: Low-pressure gas/liquid transportation

Printing/Identification: Colored pipes, pipes with LOGO function

VIII. About Us

Headquarters: Shandong, China

Established: 2014

Market Distribution: Domestic 35%, North America 9%, South Asia/South America/Eastern Europe/Middle East each 7%~5%

Company Scale: 3 branch factories, 2 major industrial parks, 100+ employees, 10+ years professional experience

Service Philosophy: Quality first, turnkey project, full-process technical support. Supports OEM customization, permanent online video technical support.