EPDM Waterproofing Membrane Production Line -- High-Performance Waterproof Material Production Solution

I. Product Description

The EPDM waterproofing membrane production line is an automated equipment system specifically designed for manufacturing ethylene propylene diene monomer (EPDM) rubber waterproofing membranes. This line utilizes EPDM mixed with other raw materials, employing extrusion and continuous vulcanization processes to produce high-performance EPDM membranes. The line features a high degree of automation, simple operation, and facilitates precise quality control, meeting standardized production requirements. The entire system adopts a modular design, allowing for customized configurations based on specific client needs, accommodating various specifications and production capacities.

EPDM Membrane Characteristics:

Excellent Weather Resistance: Can withstand long-term exposure to outdoor environments, resisting UV rays, ozone, and other natural elements, ensuring a long service life.

Superior Aging Resistance: Possesses outstanding anti-aging properties, maintaining stable physical performance over extended use.

High Strength & High Elongation: High tensile strength and significant elongation, capable of adapting to substrate deformation and movement.

Wide Temperature Range: Maintains good physical properties within a temperature range of -40°C to 120°C.

Environmentally Friendly & Odorless: The material itself is odorless, contains no harmful substances, and complies with environmental standards.

Chemical Corrosion Resistance: Good resistance to acids, alkalis, salts, and other chemicals.

II. Equipment Advantages (Core Selling Points)

High Automation: The entire line uses a PLC automatic control system, achieving fully automated production from batching to winding, reducing manual intervention, and improving efficiency.

Easy Operation: User-friendly HMI design allows operators to get started after simple training, lowering technical skill requirements.

Stable & Controllable Quality: Precise temperature, pressure, and speed control systems ensure stable product quality with minimal batch-to-batch variation.

Energy Saving & Eco-friendly: Utilizes high-efficiency motors and heat recovery systems to reduce energy consumption; production process emits no harmful substances, meeting environmental standards.

Continuous Vulcanization Technology: Employs advanced continuous vulcanization process for high production efficiency, uniform product quality, and excellent performance.

Modular Design: Each unit is modular, facilitating installation, maintenance, and upgrades, allowing flexible configuration adjustments based on production needs.

Turnkey Service: We provide comprehensive turnkey project services, from project planning, equipment design & manufacturing, installation & commissioning, to personnel training and technical support, ensuring clients can quickly commence production and achieve expected benefits.

Turnkey services include: Project requirement analysis & solution design, Customized equipment design & manufacturing, Production line installation & commissioning, Operator technical training, Production process optimization guidance, Long-term technical support & maintenance, Raw material selection & formulation optimization advice, Product quality testing method guidance.

III. Technical Parameter Table

| Parameter Name | Parameter Value | Unit | Remarks |

| Max Production Width | 2000 | mm | Customizable |

| Membrane Thickness Range | 1.0-3.0 | mm | Adjustable |

| Line Speed | 1-10 | m/min | Stepless Speed Regulation |

| Extruder Model | Φ120/18D | - | Cold Feed Extruder |

| Main Motor Power | 110 | kW | Frequency Control |

| Vulcanization Method | Hot Air Continuous Vulcanization | - | Microwave Vulcanization Optional |

| Vulcanization Temperature | 160-200 | °C | Adjustable |

| Vulcanization Chamber Length | 30 | m | Customizable |

| Cooling Method | Water Cooling | - | Multi-Roll Cooling |

| Winding Diameter | 1000 | mm | Automatic Roll Change |

| Total Installed Power | Approx. 250 | kW | Depends on Configuration |

| Overall Dimensions | 60×6×4 | m | L×W×H |

| Equipment Weight | Approx. 40 | Ton | Depends on Configuration |

IV. Formulation Table

Below is an example formulation for EPDM waterproofing membrane production, adjustable based on specific application requirements:

| Material Name | Ratio (phr) | Function | Remarks |

| EPDM Rubber | 100 | Base Material | Provides excellent weather resistance & elasticity |

| Carbon Black N550 | 60 | Reinforcing Filler | Improves strength & wear resistance |

| Paraffin Oil | 40 | Plasticizer | Improves processability & flexibility |

| Zinc Oxide | 5 | Activator | Promotes vulcanization reaction |

| Stearic Acid | 1 | Lubricant/Activator | Improves processability & dispersion |

| Antioxidant RD | 1.5 | Anti-aging Agent | Prevents thermo-oxidative aging |

| Accelerator M | 0.8 | Vulcanization Accelerator | Speeds up vulcanization process |

| Accelerator TMTD | 1.2 | Vulcanization Accelerator | Provides fast vulcanization |

| Sulfur | 1.5 | Vulcanizing Agent | Forms cross-linked network |

| Other Additives | 2-5 | Functional Additives | Added as needed |

V. Equipment List

| No. | Equipment Name | Specification Model | Qty | Main Function |

| 1 | Auto Batching System | BPL-1000 | 1 Set | Precise weighing of various raw materials |

| 2 | Internal Mixer | X(S)N-75/40 | 1 Unit | Mixing rubber & compounding agents |

| 3 | Open Mill | XK-450 | 1 Unit | Supplemental mixing & preheating of compound |

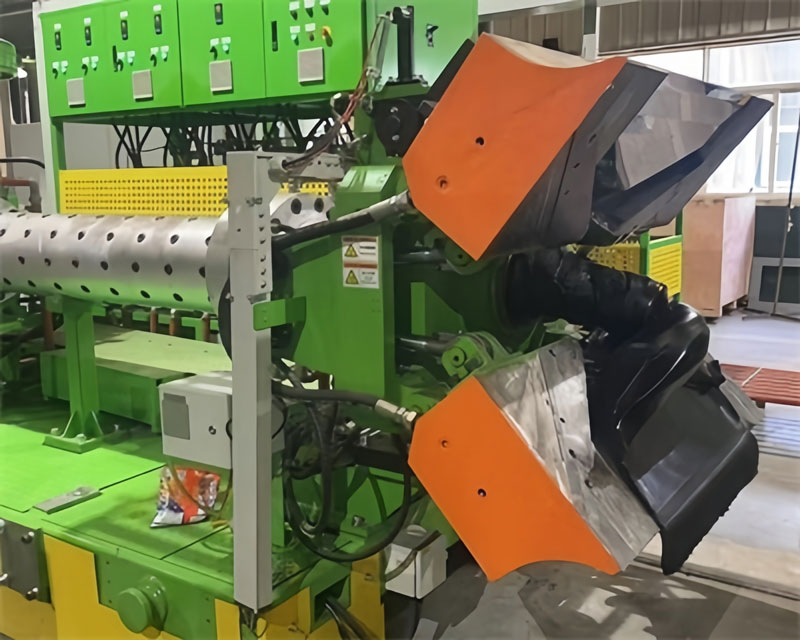

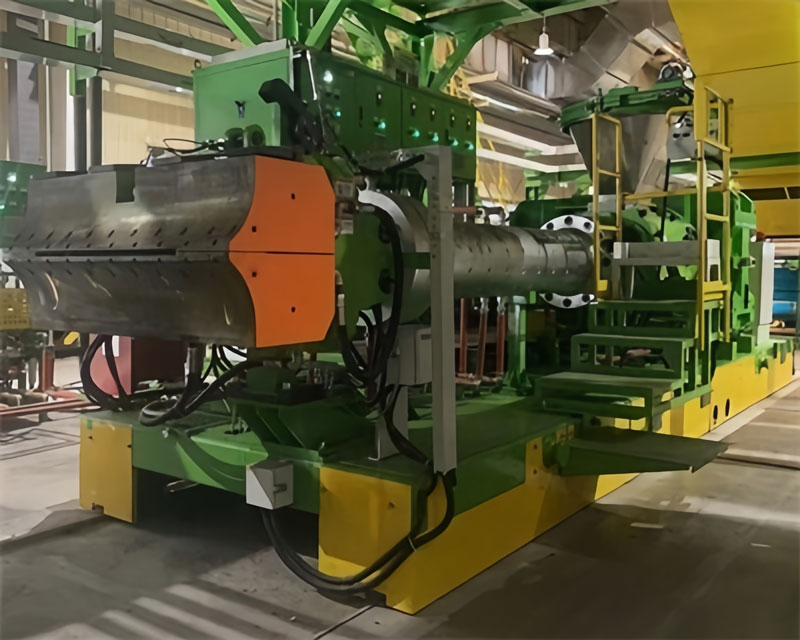

| 4 | Cold Feed Extruder | Φ120/18D | 1 Unit | Extrusion forming of compound |

| 5 | Extruder Head | 2000mm | 1 Set | Forms membrane blank of specified width |

| 6 | Continuous Vulcanization Unit | LS-30 | 1 Set | Continuous vulcanization of membrane |

| 7 | Cooling Unit | CL-2000 | 1 Set | Cooling & setting of membrane |

| 8 | Cutting Unit | CD-2000 | 1 Set | Fixed-length cutting of membrane |

| 9 | Winding Unit | W-1000 | 1 Set | Automatic winding of finished membrane rolls |

| 10 | Electrical Control System | PLC+HMI | 1 Set | Automated control of entire line |

| 11 | Auxiliary Equipment | - | 1 Batch | Includes pay-off, accumulator, etc. |

VI. Process Flow Chart

EPDM Waterproofing Membrane Production Process Flow Chart

Weighing & Batching → Internal Mixing → Open Mill Mixing → Extrusion Forming → Continuous Vulcanization → Cooling & Setting → Cutting → Winding → Inspection & Packaging

Process Description:

Weighing & Batching: Precisely weigh EPDM rubber, carbon black, oils, and other compounding agents according to the formulation ratio.

Internal Mixing: Add weighed raw materials into the internal mixer for mixing, ensuring uniform dispersion of all compounding agents in the rubber.

Open Mill Mixing: Perform supplemental mixing and preheating of the internally mixed compound on the open mill, preparing it for the extrusion process.

Extrusion Forming: The preheated compound passes through the cold feed extruder and head to form a membrane blank of specified width and thickness.

Continuous Vulcanization: The extruded membrane enters the continuous vulcanization unit, completing the vulcanization reaction at high temperature to form a cross-linked structure.

Cooling & Setting: The vulcanized membrane passes through the cooling unit for rapid cooling and setting.

Cutting: The cooled and set membrane is automatically cut to the set length.

Winding: The cut membrane is wound into rolls of specified length via the automatic winding unit.

Inspection & Packaging: Quality inspection of finished membrane rolls, packaging and labeling of qualified products, preparing for shipment.

VII. Application Fields

The high-performance waterproofing membranes produced by the APEX EPDM production line are widely used in the following areas:

Building Waterproofing: Roof waterproofing, underground engineering waterproofing, bathroom waterproofing, etc.

Municipal Engineering: Subway, tunnel, bridge, culvert waterproofing projects.

Water Conservancy Projects: Reservoir, canal, dam waterproofing & protection.

Transportation Engineering: Highway, railway, airport waterproofing projects.

Industrial Buildings: Factory, warehouse, cold storage waterproofing projects.

Special Projects: Landfill sites, sewage treatment plants, and other environmental protection project waterproofing.

Sports Facilities: Stadiums, swimming pools, etc. waterproofing projects.

VIII. Energy Saving & Cost Reduction

APEX's electrical control cabinets and motor systems achieve comprehensive energy savings of 5%-60% through integrated technologies like variable frequency speed regulation, intelligent control, and high-efficiency hardware design. Core energy-saving mechanisms include:

1. Variable Frequency Speed Regulation: Dynamically matches load demand (Energy saving contribution: 10%-35%)

2. Intelligent Control System: Multi-dimensional optimization of energy efficiency (Energy saving contribution: 5%-15%)

3. High-Efficiency Hardware Design: Reduces basic losses (Energy saving contribution: 3%-10%)

IX. About APEX

We are a high-tech enterprise specializing in the R&D, manufacturing, and service of polymer material processing equipment, committed to providing advanced waterproofing membrane production solutions for our clients.

Company Profile

Headquarters: Qingdao, Shandong, China, Founded: 2014, Scale: 3 branch factories, 2 major industrial parks, Employees: 100+ professional technical staff, Experience: 10+ years of professional experience.

Market Distribution: Domestic Market: 35%, North American Market: 9%, South Asian Market: 7%, South American Market: 7%, Eastern European Market: 6%, Middle Eastern Market: 5%.

Service Commitment

Quality First: Strict quality control system

Turnkey Projects: Comprehensive solutions

Customized Services: Support for OEM and customized production

Permanent Online Technical Support: 7×24 hours online service

Full-Process Technical Support: Guidance from design to production