Simulation Small Green Plant-Flower Injection Molding Machine

I. Product Description

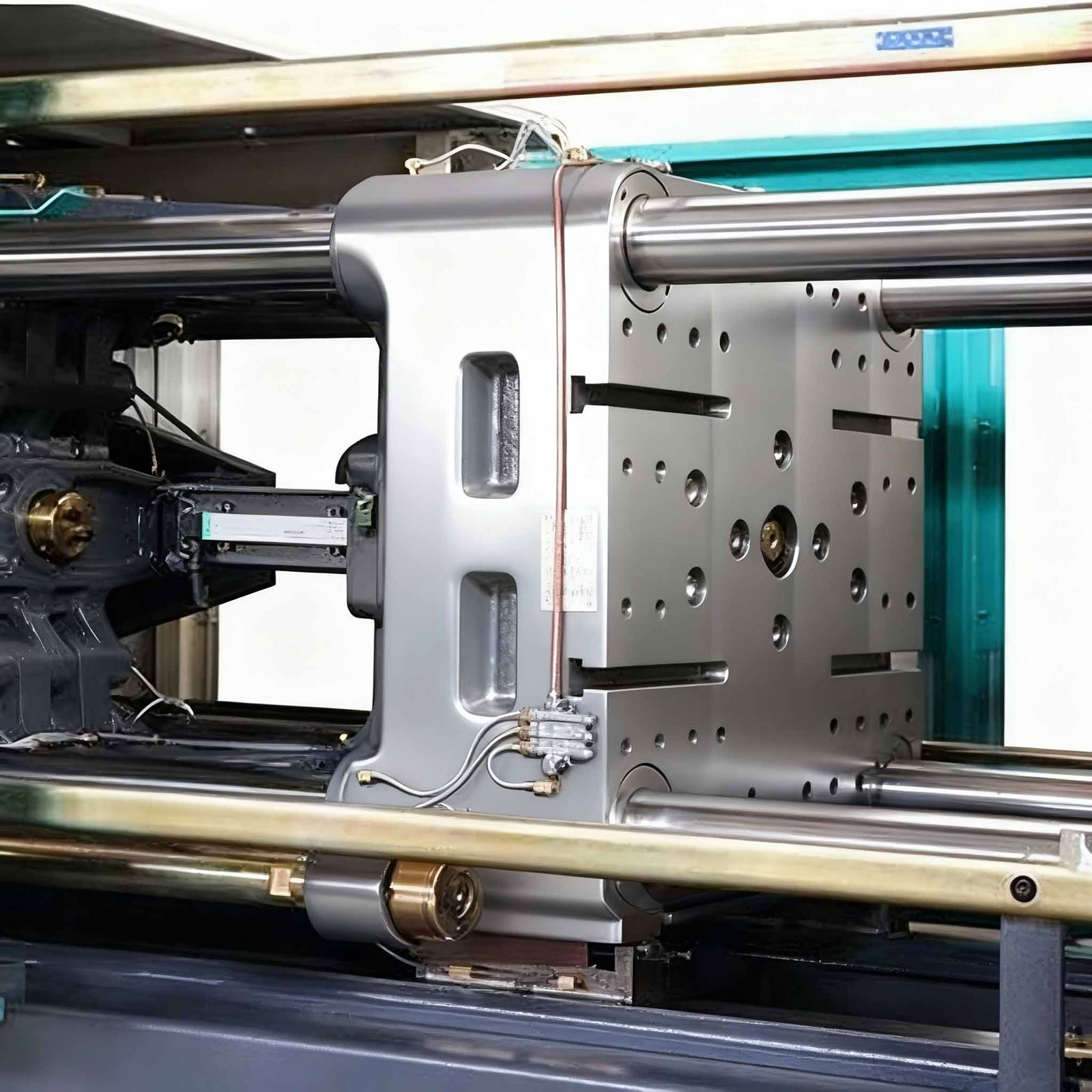

This high-quality hydraulic injection molding machine is specially designed for efficient plastic processing, supporting various thermoplastic materials including ABS, PC, PVC, PP, PE, etc. Equipped with a powerful clamping force of 1800 kN,

the machine has a screw diameter ranging from 45 mm to 52 mm and features automatic operation to improve production efficiency.

CE Certification: Complies with EU safety standards, ensuring global market access and reliability

Energy-Saving Design: Compact size (5.03m × 1.33m × 1.7m) and efficient energy-saving design make it an ideal choice for manufacturing plants

Versatility: Supports processing of various plastic materials, including PP, PC, ABS, PVC, HDPE, PS, etc.

II. Equipment Advantages (Core Selling Points)

Energy-Saving and Efficient: Adopts high-efficiency hydraulic system and energy-saving design to reduce energy consumption costs

High-Precision Control: PLC control system ensures precise control of the production process

Multi-Material Support: Compatible with various thermoplastics to meet different product requirements

Automated Production: Automatic operation function improves production efficiency and reduces manual intervention

Quality Assurance: CE certified, compliant with international safety standards

Durable and Reliable: Core components are made of high-quality materials to ensure long-term stable operation of the equipment

Supplier Highlights: Manufacturer and Trader: Direct source with price advantages

Full Customization Services: Provides full customization, design customization, and sample customization services

Product Certification: Passed relevant product certifications, quality guaranteed

High Satisfaction Rate: Customer satisfaction rate as high as 99.9%

Turnkey Service: We provide complete turnkey solutions

III. Technical Parameter Table

| Item | Unit | APK180 |

|

|

| Injection Unit | Screw Diameter | 45 mm | 50 mm | 52 mm |

| Injection Volume | cm³ | 357 | 441 | 477 |

| Injection Weight | g | 325 | 402 | 434 |

| Injection Pressure | MPa | 195 | 158 | 146 |

| Clamping Force | KN | 1800 |

|

|

| Opening Stroke | mm | 435 |

|

|

| Mold Thickness (Min-Max) | mm | 200-540 |

|

|

| Space Between Tie Bars | mm | 480×480 |

|

|

| Ejection Force | KN | 53 |

|

|

| Ejection Stroke | mm | 135 |

|

|

| Motor Power | kW | 18.5 |

|

|

| Heater Power | kW | 12.4 |

|

|

| Pump Pressure | MPa | 16 |

|

|

| Machine Dimensions | m | 5.03×1.33×1.7 |

|

|

| Machine Weight | T | 5 |

|

|

IV. Formula Table

| Raw Material Name | Ratio (%) | Function |

| Polypropylene (PP) | 50-60 | Base Material |

| Polyethylene (PE) | 10-15 | Toughening Agent |

| Calcium Carbonate (CaCO₃) | 15-25 | Filler |

| Masterbatch | 2-5 | Colorant |

| Antioxidant | 0.5-1 | Stabilizer |

| UV Absorber | 0.5-1 | Stabilizer |

| Plasticizer | 3-5 | Flexibilizer |

V. Equipment List

| Serial No. | Equipment Name | Specification & Model | Quantity | Remarks |

| 1 | Simulation Small Green Plant Making Machine | APK180 | 1 Unit | Main Equipment |

| 2 | Mold System | Customized | 1 Set | Customized according to product requirements |

| 3 | Automatic Feeding System | ALS-400 | 1 Set | Automatic material preparation |

| 4 | Cooling System | WCS-180 | 1 Set | Water circulation cooling |

| 5 | PLC Control System | CCS-90 | 1 Set | Automated control system |

| 6 | Hydraulic System | Integrated | 1 Set | High-efficiency and energy-saving hydraulic unit |

| 7 | Safety Protection Device | Standard | 1 Set | Complies with CE safety standards |

| 8 | Operation Manual and Technical Documents | - | 1 Set | Including installation, operation and maintenance guides |

VI. Process Flow Chart (Table)

Injection Molding Process Flow of Simulation Small Green Plants

Raw Material Preparation: Mix raw materials according to formula ratio → Convey to hopper via automatic feeding system

Preheating and Melting: Raw materials in the hopper enter the heating cylinder → Melt via heater and screw shear heat

Injection Molding: Molten plastic is injected into the mold through the injection system → Pressure holding, cooling and setting

Mold Opening and Part Removal: Mold opens → Ejection system ejects the molded product

Post-processing: Remove gate and burrs → Inspection → Packaging and warehousing

Key Process Parameters: Injection Temperature: 180-220°C (adjust according to material), Mold Temperature: 40-60°C, Injection Pressure: 146-195 MPa (adjust according to screw diameter), Holding Time: 10-30 seconds, Cooling Time: 20-40 seconds

VII. Application Fields

Indoor and outdoor simulation green plant manufacturing, Commercial space decoration simulation plant production, Residential community greening decoration material manufacturing, Festival celebration decoration simulation plant production, Decoration material manufacturing for public places such as hotels and shopping malls,

Office environment greening decoration, Home decoration simulation plant production, Gift and craft manufacturing

VIII. About Us

We are a professional supplier of simulation plant manufacturing equipment with rich industry experience and technical accumulation.

Company Overview

Headquarters: Shandong, China, established in 2014

Scale: 3 branch factories, 2 major industrial parks, 100+ employees, 10+ years of professional experience

Market Distribution: Domestic: 35%, North America: 9%, South Asia/South America/Eastern Europe/Middle East: 7%~5% each

Service Commitments:

Quality first, strictly control product quality

Turnkey projects, providing full-process technical support

Support OEM customization to meet customers' personalized needs

Permanent online video technical support to promptly solve customer problems

2-year warranty period, providing mechanical test reports and video factory inspection services