Hair Wig Combing Shaping Machine / Fluffing Setting Machine

I. Product Description

Synthetic hair fiber wig combing shaping machine / fluffing setting machine is a core equipment specifically designed for the production of high-end synthetic hair products such as wigs, hair wefts, and hairpieces. This equipment is mainly used to precisely comb, uniformly orient, preliminarily shape mixed synthetic fibers (such as EPDM, protein silk, high-temperature silk, etc.), and through subsequent fluffing and setting processes, give the fibers good airiness, elasticity, and natural fluffiness, thereby significantly improving the realism, comfort, and aesthetics of the wig. This equipment is a key link in the synthetic hair product production line and is widely used in automated and semi-automated wig manufacturing factories. It is an essential equipment for achieving high-value-added, high-fluffiness hair fiber products.

II. Equipment Advantages (Core Selling Points)

✅ Turnkey Service Provides equipment + EPDM specific formula + process technology + after-sales support, customers need no additional R&D, achieving 'turnkey ready for production'

✅ Specialized Machine Customized for synthetic hair fiber (like EPDM, protein silk, etc.) characteristics, optimizes combing and fluffing effects, reduces fiber breakage and energy consumption

✅ Eco-friendly Formula Compatibility Supports eco-friendly materials like EPDM, complies with international environmental and safety standards, suitable for export markets

✅ Uniform and Stable Shaping Fibers are oriented uniformly after roller combing, providing an ideal foundation for subsequent fluffing and setting, ensuring good product consistency

✅ Automated Control Uses PLC + touch screen control, supports parameter setting and production monitoring, simple operation, high efficiency

✅ Combined Fluffing & Setting Can seamlessly connect with upstream opening and downstream drying equipment, supports whole line integration and continuous production

✅ Mature Process 10+ years of industry experience, equipment structure and process parameters optimized and verified multiple times, stable and reliable

✅ Supports Custom Branding Supports ODM/OEM, equipment functions, capacity, appearance can be customized according to customer needs, meeting brand requirements

✅ Permanent Technical Support Provides permanent online video technical support, remote assistance for process and equipment issues

III. Technical Parameter Table

| Item | Parameter Details |

| Capacity | 150 ~ 400 kg/day (depending on raw material and configuration) |

| Applicable Raw Materials | EPDM fiber, protein silk, high-temperature silk, synthetic fiber |

| Equipment Power | 8 ~ 18 kW (including motor and heating) |

| Working Voltage | 380V / 50Hz (can be customized) |

| Equipment Dimensions (Main Unit) | L2500 × W1200 × H1800 mm |

| Control Method | PLC control system + Touch screen HMI |

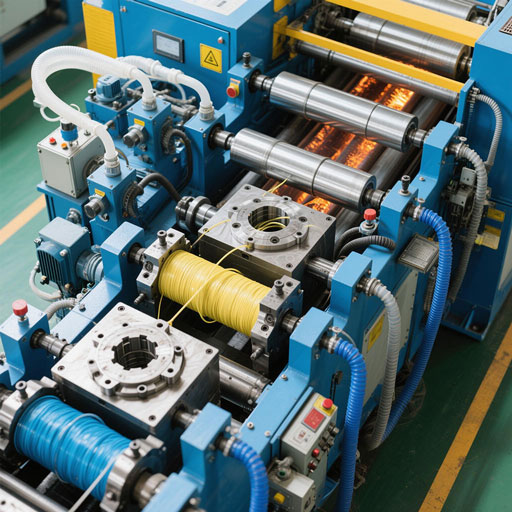

| Heating Method | Electric heating / Hot air assist (optional) |

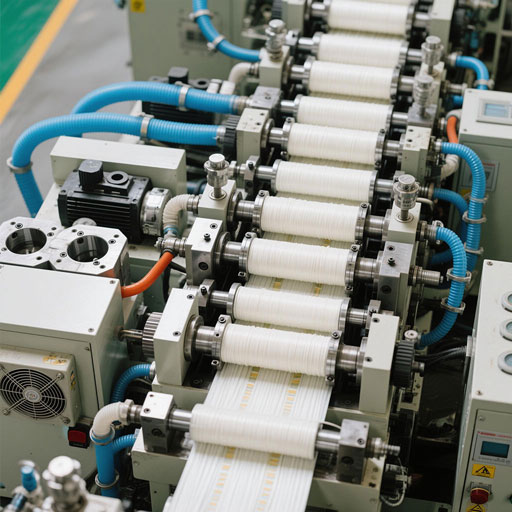

| Combing Method | Roller combing + Airflow assist (some models) |

| Automation Level | Semi-automatic / Fully automatic (can be customized) |

IV. Formula Table (EPDM Specific)

| Component | Proportion (%) | Function |

| EPDM Rubber Base Material | 60~70% | Main material, provides elasticity and structural strength |

| Filler (e.g., Calcium Carbonate) | 15~25% | Adjusts hand feel, reduces cost, improves specific gravity |

| Softening Oil (Naphthenic/Paraffin Oil) | 5~10% | Improves softness and processability |

| Additives (Antioxidant/Dispersant) | 1~3% | Enhances stability, prevents material aging |

| Color Masterbatch (Optional) | As required | For fiber coloring, meets diverse needs |

V. Equipment List (Core Components)

| 1 | Combing Main Unit | Achieves fiber directional combing and preliminary shaping |

| 2 | Feeding Device | Evenly conveys mixed fiber raw materials |

| 3 | Roller Combing System | Multiple roller sets open and orient fibers |

| 4 | Discharge Conveying System | Transports combed fibers to next process (e.g., drying/setting) |

| 5 | Electrical Control Cabinet | PLC control, supports parameter setting and status monitoring |

VI. Process Flow Chart

Raw Material Mixing: Mix EPDM, additives, fillers, etc., according to formula ratio

↓

Feeding & Combing: Mixed material enters combing machine, gradually opened and oriented by rollers

↓

Fiber Shaping: Forms uniform fiber web or layer after combing, preparing for subsequent fluffing/setting

↓

Output & Connection: Conveyed to drying or setting equipment to complete subsequent processes

VII. Application Fields

Wig Manufacturing Used for producing high-fluffiness, high-simulation wigs, hair wefts, hairpieces, improving wearing effect

Hair Accessories Hair clips, hair ties, headwear, etc., requiring lightweight and elastic fibers for decorative use

Fashion Accessories Fashion headwear, hat decorations, etc., pursuing natural fluffy effects

Model/Film & TV Props Used for highly realistic film, TV, and stage hair product production

VIII. About Us

Headquarters: Qingdao, Shandong, China

Founded: 2014 (Focus on hair product equipment for 10+ years)

Market Distribution: Domestic China: 35%, North America: 9%, South Asia, South America, Eastern Europe, Middle East: 7% ~ 5% each

Enterprise Scale: 3 branch factories | 2 major industrial parks, Employees: 100+, Professional Experience: 10+ years

Service Commitment:

Quality first, provide turnkey projects

Full-process technical support, covering equipment, process, formula

Support OEM/ODM customization, meet brand individualization needs

Permanent online video technical support, worry-free remote assistance