Plastic Synthetic Eyelash Filament Extrusion Line

I. Product Description

The Plastic Synthetic Eyelash Filament Extrusion Line is a professional plastic extrusion system specifically designed for producing high-quality false eyelash filaments and single filaments for simulated eyelashes. This production line uses high-precision molds and process control to melt high-quality plastic raw materials (such as PP, PE, PET, etc.), uniformly extrude them through a specially designed miniature T-die, and then undergo cooling, drawing, winding, and other processes to produce extremely fine, soft, highly realistic, safe, and environmentally friendly eyelash filaments. It is a key equipment in the false eyelash manufacturing industry.

II. Equipment Advantages (Core Selling Points)

We provide a true 'turnkey' overall solution, covering equipment, formulations, processes, and after-sales service, allowing you to start production without worries:

Complete Equipment: Includes raw material handling, precision extruder, miniature die, cooling system, drawing, winding, etc.

Specialized Formulations: Provide optimized EPDM (or PP/PE/PET) formulations to ensure filament softness, realism, and safety

Mature Process: 10+ years of experience in false eyelash filament extrusion, precise control of filament diameter, softness, and strength

Turnkey Service: Equipment + Formulation + Process Technology + After-sales Support, one-stop implementation

Support OEM Customization: Customize brand, appearance, and packaging according to customer needs

Permanent Online Technical Support: Remote video guidance, process optimization, problem diagnosis

III. Technical Parameter Table

| Item | Parameter |

| Applicable Raw Materials | PP, PE, PET, etc. |

| Extruder Type | Single Screw (Precision Type) |

| Screw Diameter | Φ30~Φ65 mm |

| Die Type | Miniature T-Die (Ultra-fine filament, single filament/few holes) |

| Filament Diameter Range | 0.02~0.08 mm (20~80 microns, ultra-fine simulated filament) |

| Number of Die Holes | 1~12 holes (ultra-fine filament, high control precision) |

| Line Speed | 1~10 m/min (fine control) |

| Control System | PLC + Precise Temperature Control + Drawing Control |

| Cooling Method | Water Bath Cooling (Low temperature stability) |

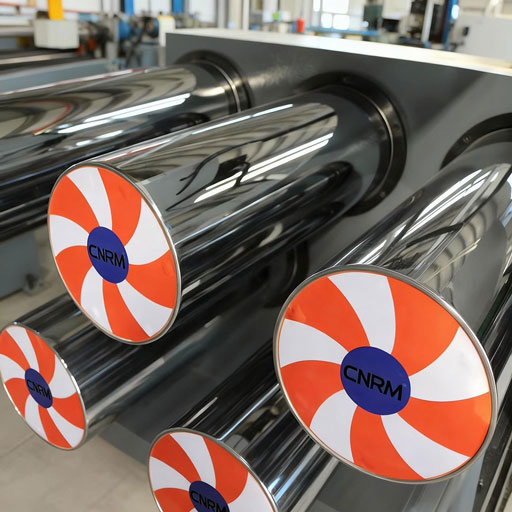

| Winding Method | Precision Winding, suitable for subsequent slitting/eyelash implantation |

IV. Formulation Table (Example: PP-based Eyelash Filament)

| Component | Proportion (%) | Function |

| PP / PE / PET | 85~93% | Base material, determines basic filament properties |

| Softening Modifier | 3~8% | Enhances soft touch, simulates natural eyelashes |

| Color Masterbatch | 1~3% | Provides natural hair color or dyeing base |

| Lubricant | 0.2~1% | Improves processing flowability, prevents sticking |

| Antistatic/Slip Agent | 0.3~1% | Reduces friction, improves wearing comfort |

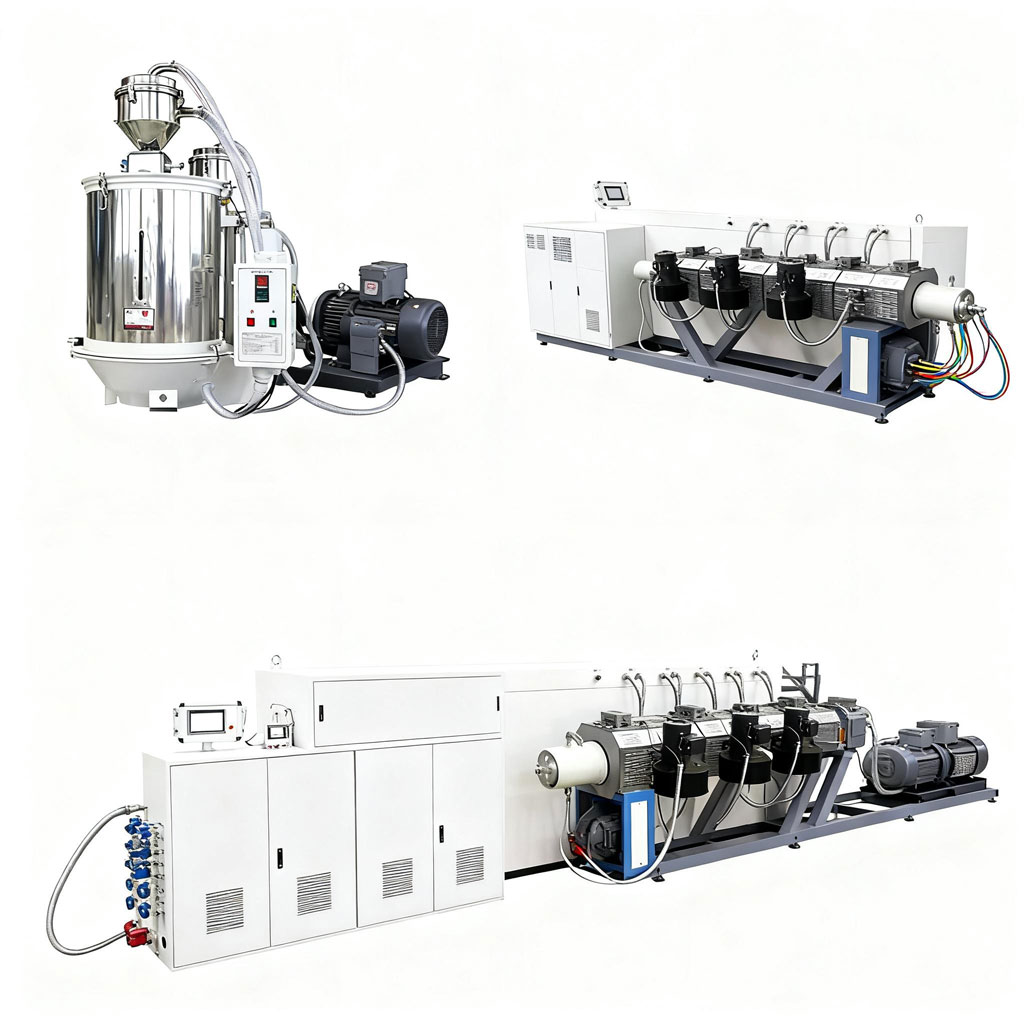

V. Equipment List (Typical Configuration)

| No. | Equipment/System | Function |

| 1 | Raw Material Mixing/Drying System | Ensures raw material purity and dryness |

| 2 | Single Screw Extruder | Precision melting and plasticizing |

| 3 | Miniature T-Die | Ultra-fine filament extrusion (single filament/few holes) |

| 4 | Cooling Water Bath | Uniform cooling and shaping |

| 5 | Drawing Device | Controls filament strength and softness |

| 6 | Winding Machine | Precision winding, convenient for subsequent processing |

| 7 | Electrical Control System | Precise temperature and speed control |

VI. Process Flow Chart

[Raw Material Mixing] → [Drying] → [Extruder Melting] → [Miniature Die Extrusion] → [Cooling Water Bath Shaping]→[Drawing Device] → [Winding Machine] → [Post-processing/Slitting/Eyelash Implantation]

VII. Application Fields

False Eyelash Manufacturing (Film, TV, Stage, Daily Use, Cosplay)

Cosmetic Products, False Eyelash Brand Owners

Personalized Customization, High-end Simulated Eyelashes

Export Markets (Europe, America, Japan, Korea, Middle East, etc.)

VIII. About Us

Headquarters: Shandong, China

Established: 2014 (Focus on plastic extrusion equipment for 10+ years)

Market Distribution:Domestic: 35%,North America: 9%,South Asia/South America/Eastern Europe/Middle East: 7%~5% each

Enterprise Scale: 3 branch factories, 2 major industrial parks, 100+ employees

Service Principle: Quality First, Turnkey Project, Full-process Technical Support, Support OEM Customization, Permanent Online Video Technical Support