Wide Film Extrusion Calendering Production Line -- High-Performance Film Production Solution

I. Product Description

The Wide Film Extrusion Calendering Production Line is an advanced equipment system specifically designed for producing high-performance wide films. This line integrates key components such as a feeding conveyor, pin-type cold-feed extruder, wide extrusion die head, edge trim recycling system, two-roll calender, cooling device, and winding device, achieving a fully automated production process from raw material to finished product.

The equipment can produce film products with a wide range of widths, particularly suitable for industrial applications requiring high dimensional accuracy, surface quality, and physical properties. The production line adopts a modular design and can be custom-configured according to specific customer requirements, meeting different specifications and production capacities.

II. Equipment Advantages (Core Selling Points)

High Production Efficiency: The line uses a wide extrusion die head design, significantly increasing single-pass production width, enhancing production efficiency, and reducing unit production costs.

Excellent Product Quality: The precision two-roll calendering system ensures uniform film thickness, smooth surface, and stable physical properties, meeting high-end application needs.

Energy-saving & Eco-friendly Design: The edge trim recycling system enables automatic recovery and reuse of scrap, reducing raw material waste and production costs, aligning with eco-friendly production concepts.

Intelligent Control System: Utilizes advanced PLC control system for precise control of production parameters, easy operation, and fault self-diagnosis function improves equipment reliability.

Modular Design: Components are modularly designed for easy installation, maintenance, and upgrades, allowing flexible configuration adjustments based on production needs.

Stable & Reliable Operation: Key components use high-quality materials and precision machining processes, ensuring long-term stable operation and reducing maintenance costs.

Turnkey Service Provided: We offer comprehensive turnkey project services, from project planning, equipment design & manufacturing, installation & commissioning, to personnel training and technical support, ensuring customers can quickly start production and achieve expected benefits.

Turnkey services include: Project requirement analysis & solution design, Customized equipment design & manufacturing, Production line installation & commissioning, Operator technical training, Production process optimization guidance, Long-term technical support & maintenance.

III. Technical Parameter Table

| Parameter Name | Parameter Value | Unit | Remarks |

| Maximum Production Width | 2000 | mm | Customizable |

| Film Thickness Range | 0.5-10 | mm | Adjustable |

| Line Speed | 2-15 | m/min | Stepless Speed Regulation |

| Extruder Model | Φ120/18D | - | Pin-type Cold Feed |

| Main Motor Power | 132 | kW | Frequency Control |

| Calender Roll Diameter | 600 | mm | Hard Chrome Plated Surface |

| Calender Roll Heating Method | Electric Heating | - | PID Temperature Control |

| Cooling Method | Multi-roll Water Cooling | - | Temperature Adjustable |

| Winding Diameter | 1000 | mm | Automatic Roll Change |

| Total Installed Power | Approx. 280 | kW | Depends on Configuration |

| Overall Dimensions | 35×6×4 | m | L×W×H |

| Equipment Weight | Approx. 45 | Ton | Depends on Configuration |

IV. Formulation Table

Below is an example formulation for general-purpose film production, adjustable based on specific application needs:

| Raw Material Name | Ratio(%) | Function | Remarks |

| Natural Rubber (NR) | 60 | Base Material | Provides excellent elasticity and strength |

| Styrene-Butadiene Rubber (SBR) | 40 | Base Material | Improves processability and wear resistance |

| Carbon Black N330 | 50 | Reinforcing Filler | Enhances strength and wear resistance |

| Zinc Oxide | 5 | Activator | Promotes vulcanization reaction |

| Stearic Acid | 2 | Lubricant/Activator | Improves processability and dispersion |

| Antioxidant 4020 | 1.5 | Anti-aging Agent | Prevents thermal-oxidative aging |

| Accelerator CZ | 1.2 | Vulcanization Accelerator | Speeds up vulcanization process |

| Sulfur | 2.5 | Vulcanizing Agent | Forms cross-linked network |

| Process Oil | 8 | Softener | Improves processability and flexibility |

| Other Additives | 1.8 | Functional Additives | Added as needed |

V. Equipment List

| No. | Equipment Name | Specification Model | Qty | Main Function |

| 1 | Feeding Conveyor | B800×6000mm | 1 set | Automatically feeds material to extruder |

| 2 | Pin-type Cold-feed Extruder | Φ120/18D | 1 unit | Rubber plasticizing, mixing, and extrusion |

| 3 | Wide Extrusion Die Head | 2000mm | 1 set | Forms wide film blank |

| 4 | Edge Trim Recycling System | CRS-2000 | 1 set | Automatically trims edges and recycles scrap |

| 5 | Two-roll Calender | Φ600×2000mm | 1 unit | Precision calendering controls film thickness |

| 6 | Cooling Device | CL-2000 | 1 set | Multi-roll cooling and setting |

| 7 | Winding Device | W-1000 | 1 set | Automatically winds finished film |

| 8 | Electrical Control System | PLC+HMI | 1 set | Automated control of entire line |

| 9 | Hydraulic System | 15kW | 1 set | Provides equipment power |

| 10 | Auxiliary Equipment | - | 1 batch | Includes unwinding device, accumulator, etc. |

VI. Process Flow Chart

Wide Film Extrusion Calendering Production Process Flow:

Raw Material Prep → Auto Feeding → Extrusion Plasticizing → Wide Extrusion → Edge Trim Recycling → Precision Calendering → Cooling Setting → Quality Inspection → Auto Winding → Finished Product Packaging

Process Flow Description:

Raw Material Preparation: Prepare various rubber materials and additives according to the formulation ratio.

Auto Feeding: Transport raw materials to the extruder feed port via the feeding conveyor.

Extrusion Plasticizing: Materials are heated, sheared, and mixed in the pin-type cold-feed extruder for thorough plasticization.

Wide Extrusion: Plasticized compound passes through the wide extrusion die head to form a film blank of the required width.

Edge Trim Recycling: Precisely trims the edges of the extruded blank; trimmed scrap is automatically recycled and sent back to the extruder for reuse.

Precision Calendering: Film passes through the two-roll calender to precisely control thickness and surface quality.

Cooling Setting: Calendered film passes through the multi-roll cooling device for rapid cooling and setting.

Quality Inspection: Online inspection system monitors film thickness, width, and surface quality in real-time.

Auto Winding: Qualified film is wound into rolls of specified length by the automatic winding device.

Finished Product Packaging: Wound film rolls are packaged, labeled, and prepared for shipment.

VII. Application Fields

The high-performance films produced by the Wide Film Extrusion Calendering Production Line are widely used in the following fields:

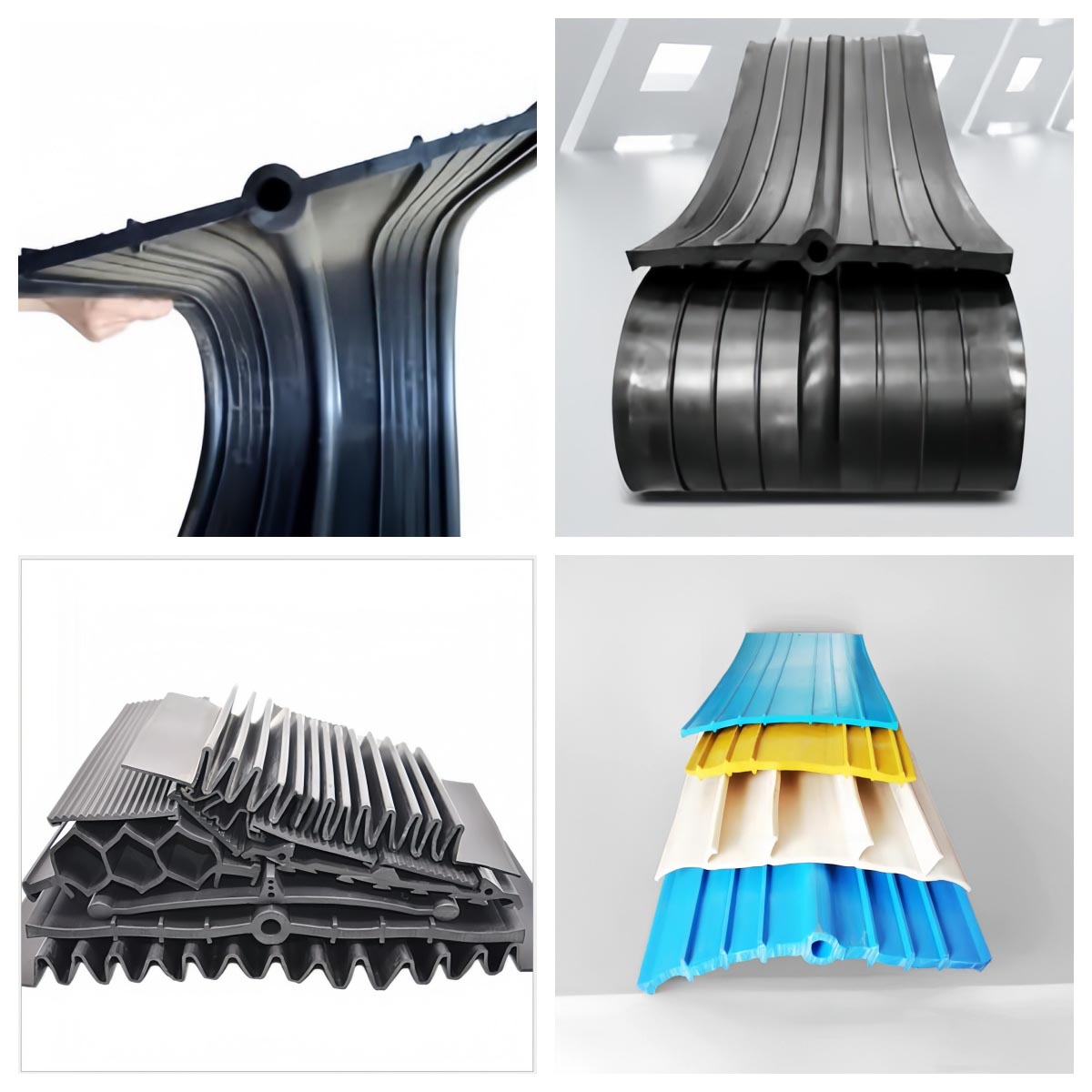

Automotive Industry: Automotive sealing strips, vibration dampers, hoses, etc.

Construction Industry: Waterproofing membranes, building sealing tapes, soundproofing materials.

Electronics & Electrical: Insulating tapes, conductive rubber, sealing gaskets.

Medical Devices: Medical tubing, protective products, medical pads.

Sports Goods: Sports shoe soles, fitness equipment parts, sports field materials.

Industrial Products: Conveyor belts, industrial rollers, sealing products.

Packaging Industry: Food-grade tapes, packaging sealing materials.

VIII. Energy Saving & Cost Reduction

The electrical control cabinets and motor systems procured by APEX achieve comprehensive electricity savings of 5%-60% through integrated technologies like variable frequency speed regulation, intelligent control, and high-efficiency hardware design. The core energy-saving mechanisms are:

1. Variable Frequency Speed Regulation: Dynamically matches load demand (Energy saving contribution: 10%-35%)

2. Intelligent Control System: Optimizes energy efficiency multi-dimensionally (Energy saving contribution: 5%-15%)

3. High-efficiency Hardware Design: Reduces basic losses (Energy saving contribution: 3%-10%)

IX. About Us

We are a high-tech enterprise specializing in the R&D, manufacturing, and service of polymer material processing equipment, committed to providing customers with advanced film production solutions.

Company Profile

Headquarters: Qingdao, Shandong, China,Founded: 2014

Scale: 3 branch factories, 2 major industrial parks,Employees: 100+ professional technical staffExperience: 10+ years professional experience

Market Distribution:

Domestic Market: 35%,North American Market: 9%,South Asian Market: 7%,South American Market: 7%,Eastern European Market: 6%,Middle East Market: 5%

Service Commitment:

Quality First: Strict quality control system

Turnkey Projects: Comprehensive solutions

Custom Services: Support for OEM and customized production

Permanent Online Technical Support: 7×24 hours online service