Artificial Christmas Tree Production Line

No.4 Line Leaf Automatic Simulation PVC Christmas Tree Making Machine - PVC wire with a diameter of approximately 0.4mm (used for making Christmas tree leaves, balancing flexibility and simulation degree)

I. Product Description

The No.4 Line Leaf Automatic Simulation PVC Christmas Tree Making Machine is an efficient and professional production equipment for artificial Christmas trees. Adopting advanced automation technology and precision control system, it can produce high-quality PVC artificial Christmas trees quickly and

stably. The equipment features easy operation, convenient maintenance and high production efficiency, suitable for Christmas tree manufacturing enterprises of all sizes.

Product Features:

• Adopts advanced PLC control system to realize automatic control of the production process

• Energy-efficient design, reducing production costs by about 30%

• Modular design for easy maintenance and one-click upgrade

• Suitable for producing Christmas trees of various specifications and colors

• Equipped with precision temperature control system to ensure stable product quality

• Four-piece knife design to ensure leaf cutting precision

• No waste generated during the entire production process

Application Scope: Suitable for producing PVC artificial Christmas trees of various sizes and styles, meeting the appearance and quality requirements of Christmas trees from different markets and customers.

II. Equipment Advantages (Core Selling Points)

Our artificial Christmas tree production line provides comprehensive turnkey services, from equipment supply to technical support, ensuring customers can quickly put into production and achieve efficient production.

Complete Equipment Solution: Provides a full set of production equipment from raw material processing to finished product packaging, ensuring the continuity and efficiency of the production process.

Special Formula Support: Provides optimized PVC formulas according to customer needs to ensure the best product performance.

Process Technology Guidance: Provides comprehensive production process guidance, including parameter setting, operation points and quality control methods.

Comprehensive After-sales Support: Provides comprehensive after-sales services such as installation and commissioning, operation training, regular maintenance and troubleshooting.

Permanent Online Technical Support: Provides permanent online technical support through video conferences and other methods to promptly solve problems encountered in the production process.

Customization Service: Supports OEM customization, and can adjust equipment configuration and production process according to customer needs.

III. Technical Parameter Table

| Parameter Name | Parameter Value | Unit | Remarks |

| Product Name | No.4 Line Leaf Automatic Artificial PVC Christmas Tree Making Machine | - | - |

| Material | Steel | - | Main Structure |

| Total Power | 3 | KW | - |

| Air Pump Pressure | 0.6 | Mpa | - |

| Specification | Four-piece Knife Set | - | Cutting System |

| Leaf Length | 5.56 | M | Length per Leaf |

| Knife Length | 135 | MM | Cutting Knife Length |

| Production Capacity | 400 | Times/Hour | Production Efficiency |

| Machine Dimension | 78907202180 | MM | LengthWidthHeight |

| Color | Standard Green or Customized | - | Product Color Options |

IV. Formula Table

| Raw Material Name | Ratio(%) | Function | Supplier Recommendation |

| PVC Resin | 50-60 | Matrix Material | Domestic/Imported Available |

| Plasticizer | 20-30 | Improve Flexibility | DOP/DOA, etc. |

| Stabilizer | 3-5 | Thermal Stabilization | Calcium-Zinc/Organotin, etc. |

| Filler | 5-15 | Reduce Cost, Improve Performance | Calcium Carbonate/Talcum Powder, etc. |

| Lubricant | 0.5-1.5 | Improve Processing Fluidity | Stearic Acid/Paraffin Wax, etc. |

| Colorant | 2-5 | Product Coloring | Mainly Green, Adjustable According to Needs |

| Other Additives | 2-5 | Improve Specific Performance | Antioxidant/Flame Retardant, etc. |

The above formula is a basic reference formula. In actual production, it will be optimized and adjusted according to the specific needs of customers (such as special requirements for color, flexibility, flame retardancy, etc.). We provide professional formula technical support to

ensure the best product performance.

V. Equipment List

| Serial No. | Equipment Name | Specification & Model | Quantity | Main Function |

| 1 | Main Production Line | PVC Christmas Tree Making Machine | 1 Set | Christmas Tree Main Body Production |

| 2 | Raw Material Mixing System | HM-500 | 1 Set | Raw Material Premixing |

| 3 | Extruder | SJ-120/30 | 1 Unit | PVC Plasticization & Extrusion |

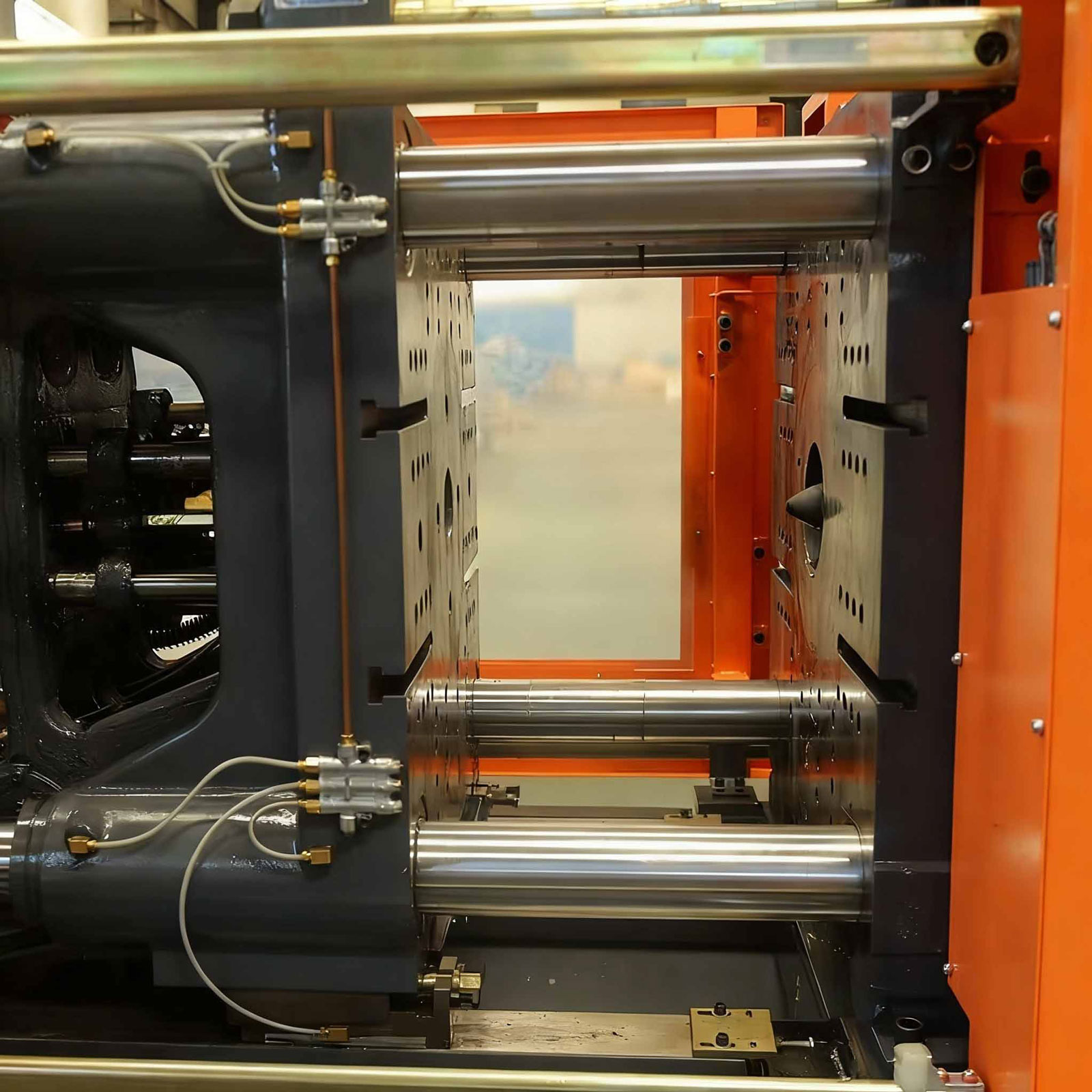

| 4 | Mold System | Customized | 1 Set | Leaf Molding |

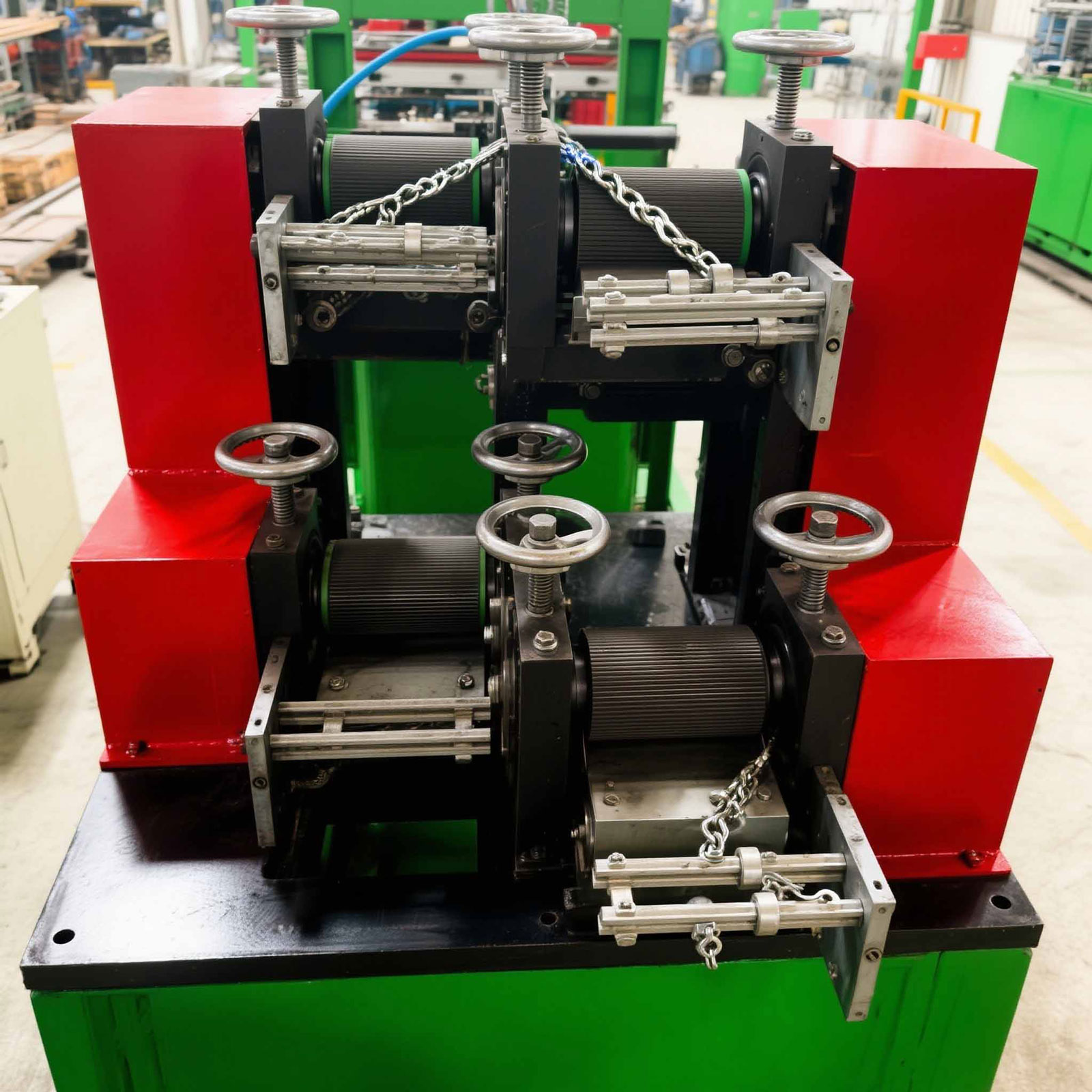

| 5 | Cutting System | Four-piece Knife Set | 1 Set | Leaf Cutting |

| 6 | Pneumatic System | 0.6 Mpa | 1 Set | Power Supply |

| 7 | Control System | PLC + Touch Screen | 1 Set | Whole Line Control |

| 8 | Assembly Table | Customized | 2 Units | Christmas Tree Assembly |

| 9 | Packaging Equipment | Automatic Packaging Line | 1 Set | Finished Product Packaging |

| 10 | Auxiliary Equipment | - | 1 Set | Including Feeding, Measuring, etc. |

VI. Process Flow Chart (Table)

1. Raw Material Preparation and Measurement: Accurately weigh various raw materials such as PVC resin, plasticizer and stabilizer according to the formula ratio

2. High-speed Mixing: Fully mix the raw materials in a high-speed mixer to ensure uniform dispersion of each component

3. Extrusion Plasticization: Heat and plasticize the mixed materials through an extruder to form a uniform melt

4. Mold Molding: Mold the molten PVC material into Christmas tree leaf shapes through special molds

5. Cooling and Setting: Pass the formed leaves through a cooling system to ensure stable shape

6. Cutting and Finishing: Precisely cut the leaves with a four-piece knife set to ensure consistent size

7. Manual Assembly: Assemble the leaves onto the tree trunk to form a complete Christmas tree

8. Inspection and Packaging: Inspect the finished products, and package qualified products for storage

Process Key Points:

• Strictly control the temperature of each section to ensure good plasticization

• Adjust the matching between extrusion speed and traction speed to ensure uniform leaf thickness

• Regularly inspect molds and tools to ensure product dimensional accuracy

• Control the temperature of the cooling system within an appropriate range to avoid product deformation

VII. Application Fields

PVC Christmas trees produced by the artificial Christmas tree production line are widely used in the following fields:

Home Decoration: Used for home Christmas decoration to create a festive atmosphere, more environmentally friendly than real trees.

Commercial Venues: Festival decoration of shopping malls, hotels, office buildings and other public places to enhance the festive atmosphere.

Event Planning: Decoration and arrangement of various festive activities and celebrations, reusable to reduce costs.

Film and Television Production: Scene setting for film and television shooting, not restricted by seasons.

Export Trade: Meet the demand for artificial Christmas trees in the international market, especially in European and American countries.

Gift Industry: Sold as holiday gifts to meet the needs of different consumers.

VIII. About Us

We are a high-tech enterprise specializing in the R&D, manufacturing and sales of polymer material processing equipment. Headquartered in Shandong, China, we were established in 2014.

Company Scale: Has 3 branch factories, 2 industrial parks, more than 100 employees, and over 10 years of professional experience.

Service Concept: Quality first, providing turnkey projects and full-process technical support.

Customization Service: Supports OEM customization and permanent online video technical support.

Market Distribution: Domestic 35%, North America 9%, South Asia 7%, South America 7%, Eastern Europe 7%, Middle East 6%, Others 29%

Our Advantages

•Continuous technological innovation and product upgrading

• Perfect after-sales service system and technical support

• Rich industry experience and professional technical team

• Flexible cooperation methods to meet different customer needs

• Advanced production equipment and strict quality control system