TPR / TPE / TPU Rubber Band Extruder -- Single/Dual Color Rubber Band Production Line

I. Product Description

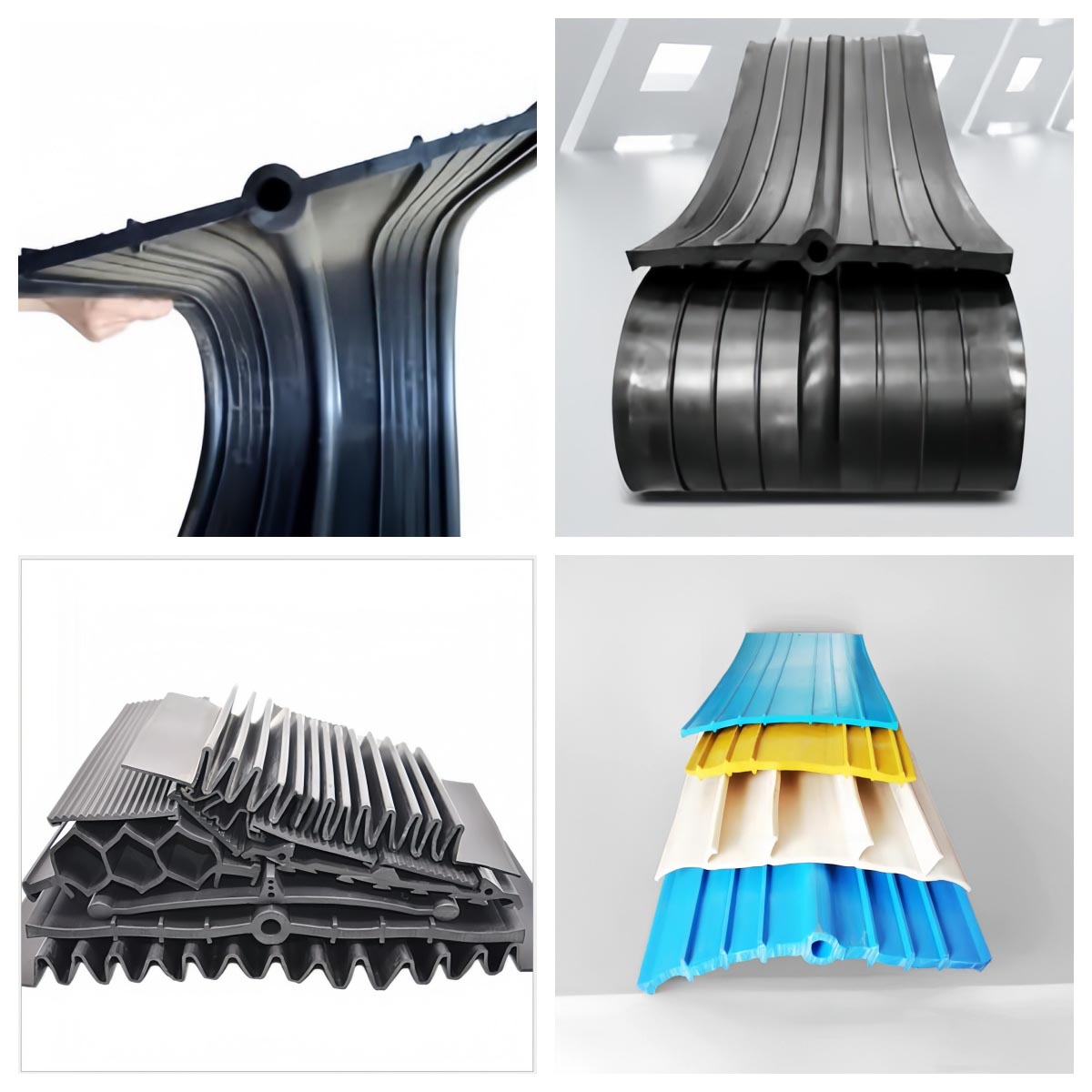

This production line is specifically designed for producing rubber bands made of TPR (Thermoplastic Rubber), TPE (Thermoplastic Elastomer), and TPU (Thermoplastic Polyurethane) materials, suitable for continuous extrusion molding of single-color or dual-color co-extruded rubber bands. The products feature high elasticity, environmental friendliness, non-toxicity, rich colors, stretch resistance, and resistance to aging. They are widely used in daily necessities, office supplies, children's toys, hair accessories, sports equipment, medical aids, and other fields.

Supports single-color extrusion and dual-color co-extrusion (e.g., color blocking, gradient colors, identification stripes), capable of producing rubber bands of different thicknesses, lengths, and strengths to meet diverse market demands.

II. Equipment Advantages (Core Selling Points)

• Optimized for TPR/TPE/TPU materials, stable extrusion, excellent elasticity, smooth surface

• Supports single-color / dual-color co-extrusion, achieving color blocking, identification, personalized customization

• Interchangeable molds, support production of rubber bands with different diameters (thickness) and cross-sectional shapes

• Continuous automated production, efficient and stable, suitable for small batch multi-variety or large-scale production

• Equipped with cooling water tank, traction wheels, winding device, achieving full automation from extrusion to coiling

• Provides turnkey service: Rubber band extruder (single/twin screw), TPR/TPE/TPU specific eco-friendly formulas, process technology (temperature, speed, co-extrusion control, etc.), after-sales support and operation training, supports OEM / custom branding, permanent online video technical support.

III. Technical Parameter Table

| Item | Parameter / Description | Typical Value / Range |

| Applicable Material | TPR / TPE / TPU | Thermoplastic Elastomer / Thermoplastic Polyurethane |

| Production Line Type | Rubber Band Extrusion Line | Supports Single / Dual Color Co-extrusion |

| Rubber Band Diameter | mm | 1.0 ~ 8.0 (Customizable) |

| Extruder | Type | Single Screw / Twin Screw |

| Screw Diameter | mm | φ30 / φ40 / φ50 |

| Output | kg/h | 2 ~ 15 (Depending on material & spec) |

| Line Speed | m/min | 5 ~ 30 |

| Traction Method | - | Multi-wheel Traction / Constant Tension Control |

| Winding Method | - | Automatic Winding / Manual Winding Optional |

| Control Method | - | Temperature Control + Speed Control |

| Dual Color Co-extrusion | - | Supports Dual Color Blocking / Gradient / Identification Line |

IV. Formulation Table (TPR/TPE/TPU Rubber Band Material System)

| Material Type | Common Materials | Function & Role |

| Base Material | TPR / TPE / TPU | Provides elasticity, flexibility, and rebound performance |

| Softener / Plasticizer | Naphthenic Oil / Paraffin Oil (Eco-friendly) | Adjusts hardness and processability |

| Stabilizer | Antioxidant / Light Stabilizer | Enhances aging and weather resistance |

| Color Masterbatch (Optional) | TPR/TPE/TPU Specific Color Masterbatch | Achieves single or multi-color effects |

| Additives | Lubricant, Processing Aid | Improves fluidity and demolding |

V. Equipment List

| No. | Equipment Name | Function |

| 1 | TPR/TPE/TPU Extruder | Material melting, plasticizing, extrusion |

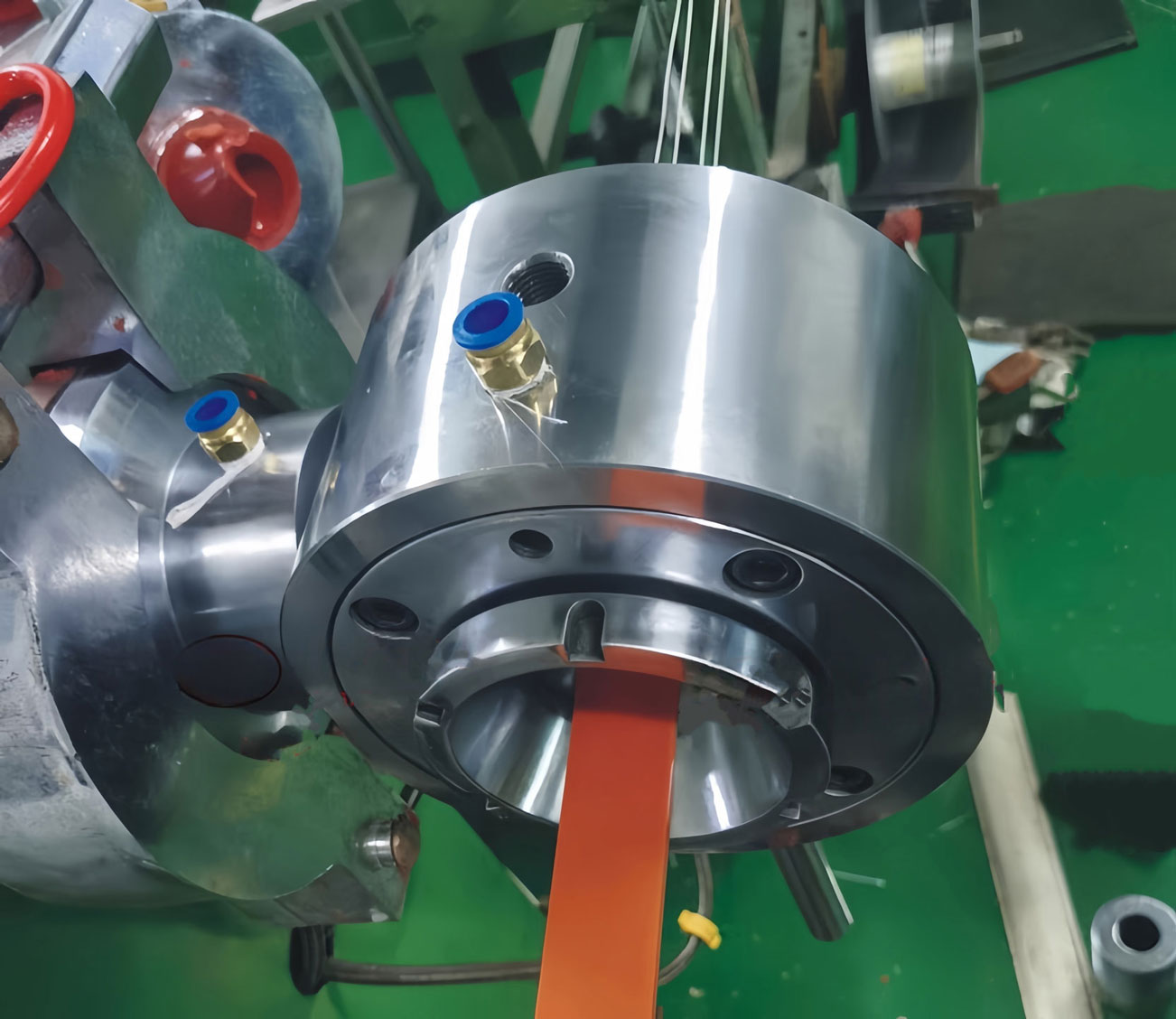

| 2 | Die (Strip Extrusion Die Head) | Controls rubber band diameter and shape |

| 3 | Cooling Water Tank | Cooling and shaping |

| 4 | Traction Device | Uniformly pulls the rubber band |

| 5 | Winding Machine | Automatic winding into coils |

| 6 | Dual Color Co-extrusion System (Optional) | Achieves dual color blocking or identification |

| 7 | Control System | Temperature / Speed Control |

VI. Process Flow Chart (Text Version)

1. Raw Material Preparation: TPR/TPE/TPU pellets and additives mixed according to formula (color masterbatch optional)

2. Mixing (Optional): Add color masterbatch, softener, mix uniformly

3. Extrusion: Melted via extruder, extruded into strip-shaped rubber band through die

4. Cooling: Cooled in water tank, shaped

5. Traction: Uniformly pulled, maintaining consistent tension

6. Winding: Automatically wound into coils for easy packaging and use

VII. Application Fields

• Daily Necessities: Rubber bands, cable ties, bundling straps

• Office Supplies: File bundling, office organization

• Children's Toys: Puzzle accessories, educational toys

• Hair Accessories: Hair ties, elastic bands, hair tying

• Sports Goods: Wristbands, ankle bands, assistance bands

• Medical Aids: Lightweight straps, fixation bands

VIII. Energy Saving & Cost Reduction

APEX's electrical control cabinets and motor systems achieve comprehensive electricity savings of 5%-60% through integrated technologies like variable frequency speed regulation, intelligent control, and efficient hardware design. The core energy-saving mechanisms are as follows:

I. Variable Frequency Speed Regulation: Dynamically matches load demand (Energy saving contribution: 10%-35%)

1. Precise Motor Speed Adjustment

• Uses inverter + PLC control cabinet combination to adjust motor speed in real-time based on actual load demand (e.g., pump, fan loads), avoiding energy waste from traditional fixed-speed 'big horse pulling small cart' operation.

• Measured data: In sewage plant lift pump applications, VFD speed control reduced energy consumption by 20%-70%; central air conditioning chilled water systems achieved 15%-30% energy savings through variable flow control.

2. Soft Start Function

• Achieves smooth motor start via inverter, eliminating inrush current during traditional starts (peak can be 5-7 times rated current), reducing equipment wear and extending motor life.

II. Intelligent Control System: Multi-dimensional energy efficiency optimization (Energy saving contribution: 5%-15%)

1. Adaptive Adjustment Strategy

Integrated PLC + touch screen control cabinet automatically adjusts equipment operation mode based on environmental parameters (temperature, pressure, flow). For example:

Air conditioning systems dynamically distribute cooling/heating, preventing zone overcooling or overheating;

Industrial equipment starts/stops on demand, reducing无效 running time.

2. Energy Consumption Monitoring & Warning

• Real-time collection of voltage, current, temperature data, using algorithms to identify abnormal energy consumption (e.g., cooling fan idling), triggering alarms or automatic shutdown.

III. Efficient Hardware Design: Reduces basic losses (Energy saving contribution: 3%-10%)

1. Low-Loss Motor Selection

• Uses IE4 high-efficiency permanent magnet synchronous motors, improving efficiency by 3%-5% compared to traditional asynchronous motors, reducing iron loss by 20%.

• Optimizes motor heat dissipation structure (e.g., forced air cooling + thermal conductive materials), reducing efficiency decay caused by temperature rise.

2. Control Cabinet Energy Saving Modification

• Segmented Resistor Design: Distributes centralized resistors into modular units, reducing无效 power loss;

• Natural Heat Dissipation Optimization: Increases cabinet ventilation area,配合 intelligent fan start/stop strategy,降低散热能耗.

• After modification: Using VFD control cabinet + high-efficiency motor, annual power consumption reduced to 780,000 kWh, electricity cost 468,000 CNY;

• Payback Period: Equipment investment approx. 500,000 CNY, annual electricity saving收益 252,000 CNY, payback period 1.98 years.

IX. About Us

Headquarters: Shandong, China

Established: 2014

Market Distribution: Domestic 35%, North America 9%, South Asia/South America/Eastern Europe/Middle East each 7%~5%

Company Scale: 3 branch factories, 2 major industrial parks, 100+ employees, 10+ years professional experience

Service Philosophy: Quality first, turnkey project, full-process technical support. Supports OEM customization, permanent online video technical support.