Top 10 Suppliers of Rubber Internal Mixers in China: Your Ultimate Guide to Leading Manufacturers

Top 10 suppliers of rubber internal mixers in China represent the forefront of innovation and manufacturing excellence in the global rubber machinery industry. If you are sourcing reliable and high-performance mixing equipment, understanding this competitive landscape is crucial for making an informed decision. This guide will walk you through the key players, helping you identify partners that can meet your specific production needs and quality standards.

Navigating the vast market of rubber machinery suppliers in China can be challenging, given the variety of options available. You need a clear, unbiased overview of the top-tier companies that have proven their capabilities through technology, service, and global reach. We have compiled this list based on comprehensive research into their market reputation, technological advancements, and customer feedback.

By exploring these leading suppliers, you will gain insights into what makes each one stand out, from their R&D capabilities to their after-sales support. This knowledge will empower you to choose a supplier that not only provides excellent machinery but also becomes a long-term strategic partner for your business growth.

1、Why Source Rubber Internal Mixers from China?

1.1、Cost-Effectiveness and Value

1.2、Advanced Manufacturing Capabilities

1.3、Rapid Technological Adoption and Innovation

1.4、Strong Global Supply Chain Integration

2、Key Criteria for Evaluating Top Suppliers

2.1、Technological Innovation and R&D Investment

2.2、Production Capacity and Quality Control Systems

2.3、Global Market Presence and Customer Portfolio

2.4、After-Sales Service and Technical Support

3、Profiles of the Leading Chinese Suppliers

3.1、Established Industry Giants with Full Product Lines

3.2、Specialized Niche Players and Technology Innovators

3.3、Rising Stars with Agile Manufacturing and Customization

3.4、Export-Oriented Suppliers with International Certifications

4、How to Choose the Right Supplier for Your Needs

4.1、Matching Machine Specifications to Your Production Goals

4.2、Assessing Customization and Co-development Capabilities

4.3、Verifying Installation, Training, and Spare Parts Logistics

4.4、Considering Long-Term Partnership and Upgrade Potential

1、Why Source Rubber Internal Mixers from China?

When you consider sourcing rubber internal mixers, China stands out as a premier destination for several compelling reasons. First, the country's manufacturing ecosystem offers an unparalleled combination of advanced technology and cost-effectiveness. Leading Chinese suppliers, such as APEX (Qingdao Aipake Machinery Technology Co., Ltd.), exemplify this by integrating robust R&D capabilities with large-scale, intelligent production. Founded in 2014, APEX operates as a high-tech enterprise specializing in high-end rubber and plastic machinery, demonstrating China's shift from mere volume production to innovation-driven manufacturing. By choosing a Chinese supplier, you gain access to state-of-the-art equipment that is both technologically sophisticated and competitively priced, directly enhancing your operational efficiency and return on investment.

Secondly, China's top suppliers have cultivated extensive global experience and a proven track record of reliability. Companies like APEX, with their products exported to over 30 countries and serving thousands of leading clients, have refined their designs and services to meet diverse international standards. This global footprint ensures that the machinery you procure is built for durability and performance across various applications, from automotive parts to medical products. Furthermore, the presence of provincial engineering centers and smart manufacturing bases within these companies guarantees continuous product improvement and strong after-sales support, providing you with a dependable long-term partnership rather than just a one-time transaction.

Finally, sourcing from China provides you with a comprehensive solution. Beyond just selling machines, elite suppliers focus on delivering complete, energy-efficient, and intelligent industrial systems tailored to your specific needs in sectors like electronics, healthcare, and construction. This holistic approach, centered on customer success, ensures that you receive not only a high-quality rubber internal mixer but also the technical expertise and service necessary to optimize your entire production process, solidifying China's position as a strategic hub for world-class rubber machinery.

1.1、Cost-Effectiveness and Value

When you source rubber internal mixers from China, the most immediate and tangible benefit you encounter is the significant cost advantage. Chinese manufacturers have mastered the art of producing high-quality machinery at a fraction of the cost you would typically find in Western or Japanese markets. This is primarily due to optimized supply chains, economies of scale, and competitive labor costs within the industrial ecosystem.

This cost-effectiveness does not equate to a compromise on value. On the contrary, the leading suppliers invest heavily in R&D, adopting advanced technologies like PLC control systems, energy-efficient designs, and robust construction to ensure their mixers meet international performance and safety standards. You get a machine that delivers reliable, precise mixing cycles, contributing directly to your production efficiency and product consistency.

Furthermore, the value proposition extends beyond the initial purchase price. Many top Chinese suppliers offer comprehensive after-sales services, including installation guidance, operator training, and readily available spare parts. This holistic support minimizes your downtime and total cost of ownership, ensuring your investment continues to pay dividends over the long operational life of the equipment.

Therefore, by choosing a reputable supplier from China, you are not just buying a cheaper machine; you are securing a cost-effective solution that offers outstanding long-term value, enabling you to allocate capital to other critical areas of your business while maintaining a competitive edge in your market.

1.2、Advanced Manufacturing Capabilities

When you source from China, you tap into a manufacturing ecosystem that has rapidly evolved from basic assembly to sophisticated, technology-driven production. Leading Chinese suppliers of rubber internal mixers operate state-of-the-art facilities equipped with CNC machining centers, automated assembly lines, and advanced quality control systems. This allows for high-precision manufacturing of critical components like rotors, mixing chambers, and frames, ensuring the durability and performance of the final machine.

You benefit from their deep integration of modern industrial technologies, such as IoT-enabled monitoring and digital twin simulations used during the R&D phase. This capability translates into mixers that are not only robust but also smarter, with better control over mixing parameters, energy efficiency, and predictive maintenance features. The scale of production also means they can achieve economies of scale, offering you competitive pricing without compromising on the core engineering quality.

Furthermore, these manufacturers have mastered the art of customization at scale. Whether you need a specific rotor design, a unique cooling system, or integration with your existing production line, their advanced capabilities allow them to engineer and build a solution tailored precisely to your process requirements, giving you a significant operational advantage.

1.3、Rapid Technological Adoption and Innovation

When you source from China, you are not just buying existing technology; you are tapping into an ecosystem of rapid technological adoption and innovation. Chinese manufacturers are exceptionally agile in integrating the latest global advancements, such as IoT connectivity, AI-driven process optimization, and energy-efficient drive systems, into their rubber internal mixers. This means the equipment you procure is often at the cutting edge, designed to improve your productivity and product consistency from day one.

This culture of innovation is driven by intense domestic competition and a strong focus on R&D. Leading suppliers invest heavily in their technical centers, collaborating with universities and research institutes to pioneer new mixing technologies, advanced rotor designs, and intelligent control systems. For you, this translates into machines that offer superior dispersion, shorter mixing cycles, and lower energy consumption compared to older-generation models.

Furthermore, the speed of iteration is remarkable. Feedback from a global clientele is quickly analyzed and used to refine product designs. If a new material or process challenge emerges in the market, Chinese engineers are often among the first to develop a mixer configuration or software update to address it. This ensures that your investment remains relevant and competitive for years to come.

Ultimately, by partnering with a top Chinese supplier, you gain access to this dynamic innovation pipeline. You benefit from continuous improvements and technological upgrades that keep your production line efficient, adaptable, and aligned with the future trends of the rubber industry.

1.4、Strong Global Supply Chain Integration

When you source from China's top rubber internal mixer suppliers, you are not just buying a machine; you are plugging into a deeply integrated global supply chain. This integration means that critical components, from high-precision gears and rotors to advanced control systems, are often sourced from specialized global partners or produced in-house with internationally certified standards. This ensures that the final product you receive meets world-class specifications and reliability.

This supply chain strength translates directly into efficiency and cost-effectiveness for your business. The seamless logistics network, from raw material procurement to final assembly and export, allows these manufacturers to optimize production cycles and reduce lead times. You benefit from faster delivery schedules and more competitive pricing without compromising on the quality or technological sophistication of the equipment.

Furthermore, this global integration fosters continuous innovation. Leading Chinese suppliers actively collaborate with international technology firms and research institutions. By tapping into this network, they rapidly incorporate the latest advancements in mixing technology, energy efficiency, and automation into their designs. Consequently, the machine you purchase is often at the forefront of industry trends, giving your production line a significant competitive edge.

Finally, a robust global supply chain underpins comprehensive after-sales support. With established international logistics and partner networks, these suppliers can efficiently provide you with genuine spare parts, dispatch technical experts, and offer timely maintenance services anywhere in the world. This reduces your machine's potential downtime and ensures long-term, reliable operation, making your investment secure and sustainable.

2、Key Criteria for Evaluating Top Suppliers

When you evaluate the top suppliers of rubber internal mixers in China, several key criteria separate industry leaders from the rest. First, you should examine their technological innovation and R&D capabilities. A company like APEX (Qingdao Apex Machinery Technology Co., Ltd.), for instance, operates a provincial engineering center and focuses on advanced, energy-saving, and intelligent solutions. This directly translates to mixers with superior precision, efficiency, and durability for your production lines.

Secondly, consider the supplier's manufacturing scale and quality control. A robust, smart production base ensures consistent product quality and reliable delivery. Third, assess their global footprint and client portfolio. Suppliers with extensive export experience to over 30 countries, serving thousands of leading clients, demonstrate proven adaptability to diverse market standards and demands, which is crucial for your international operations.

Finally, look beyond the machine itself. Comprehensive after-sales support, technical training, and the ability to provide tailored solutions for sectors like automotive, healthcare, or construction are vital. These criteria ensure you partner with a supplier like APEX, which offers not just equipment but a long-term strategic alliance for growth, combining innovation with global competitiveness.

2.1、Technological Innovation and R&D Investment

When you evaluate a top supplier of rubber internal mixers, their commitment to technological innovation and the scale of their R&D investment are non-negotiable factors. This directly translates to the machine's performance, efficiency, and your long-term return on investment. Leading manufacturers don't just assemble parts; they invest heavily in developing proprietary technologies for better mixing uniformity, energy savings, and smarter control systems.

You should look for suppliers with dedicated R&D centers, partnerships with universities, and a consistent track record of patent filings. This indicates a forward-thinking approach, ensuring their equipment evolves with industry demands like automation and Industry 4.0 integration. A strong R&D pipeline means you get access to the latest advancements, such as improved rotor designs for superior dispersion or advanced software for precise process control and data analytics.

Furthermore, substantial R&D investment is a hallmark of a company's stability and its intention to lead, not just follow. It signifies they are solving real-world production challenges—like reducing cycle times or enhancing material compatibility—which directly benefits your operational efficiency. Therefore, prioritizing suppliers who champion innovation protects your investment from premature obsolescence.

2.2、Production Capacity and Quality Control Systems

When evaluating a supplier's production capacity, you are essentially assessing their ability to meet your demand consistently and on schedule. For rubber internal mixers, this goes beyond just the number of units produced per month. You should inquire about their workshop size, the number of assembly lines dedicated to mixer production, and their inventory management for critical components. A top supplier will have a scalable and organized production flow that can handle both standard orders and customized configurations without significant delays.

Quality control systems are the backbone of a reliable manufacturing process. You need to look for suppliers who have implemented rigorous, documented quality management systems, such as ISO 9001 certification. This framework ensures that every stage of production—from raw material inspection and machining precision to final assembly and testing—adheres to strict standards. Ask about their specific inspection protocols, such as dimensional checks, hardness testing of rotors and chambers, and hydraulic/pneumatic system pressure tests.

The integration of advanced technology into quality control is a key differentiator. Leading manufacturers employ precision CNC machining centers for core components like rotors and mixing chambers, ensuring exceptional geometrical accuracy and surface finish. Furthermore, you should verify if they use real-time monitoring systems during the trial run of each mixer, collecting data on temperature, power consumption, and mixing uniformity to guarantee performance meets the design specifications before shipment.

Ultimately, a supplier's commitment to quality is reflected in their after-sales support and the longevity of their machines. A robust quality control system minimizes downtime for your operations by reducing the likelihood of premature failures. By prioritizing suppliers with transparent and advanced production and QC capabilities, you secure not just a machine, but a foundation for stable, high-quality rubber compound production in your own facility.

2.3、Global Market Presence and Customer Portfolio

When you assess a supplier's global market presence, you are essentially evaluating their proven ability to operate and succeed beyond the domestic Chinese market. A strong international footprint indicates that the company's rubber internal mixers have met diverse international standards, regulatory requirements, and the rigorous demands of global customers. Suppliers with extensive export networks across Europe, North America, Southeast Asia, and other key rubber-producing regions demonstrate a product resilience and adaptability that is crucial for your long-term operational stability.

Examining a supplier's customer portfolio provides you with tangible evidence of their reliability and performance. Leading manufacturers typically serve a prestigious list of clients, including multinational tire corporations, major automotive parts suppliers, and renowned industrial rubber product manufacturers. The presence of such blue-chip companies in their portfolio is a powerful testament to the quality, durability, and technological sophistication of their internal mixers. It suggests that the equipment has been stress-tested in high-volume, precision-driven production environments.

Furthermore, a diverse customer base across different application segments—from tire manufacturing to technical rubber goods—shows the supplier's versatility and R&D capability to tailor solutions. For you, this means the supplier likely has the experience to understand your specific niche requirements, whether you need a mixer for high-performance tire compounds or specialized polymer blends. Their global service and support network, often established to serve these international clients, also becomes a direct benefit to you, ensuring prompt technical assistance and spare parts availability wherever your plant is located.

Ultimately, a supplier's global market presence and robust customer portfolio are not just marketing points; they are risk-mitigation factors for your investment. They signal a company that is financially stable, committed to continuous innovation to stay globally competitive, and capable of providing the level of partnership and support that a sophisticated buyer like you requires to maintain a competitive edge in your own market.

2.4、After-Sales Service and Technical Support

When you invest in a rubber internal mixer, the quality of after-sales service and technical support is not an optional extra; it is a critical component of your total cost of ownership and operational continuity. Leading Chinese suppliers distinguish themselves by offering comprehensive, proactive support systems designed to maximize your equipment's uptime and performance throughout its lifecycle.

You should evaluate a supplier's service network first. Top-tier manufacturers maintain a global or extensive domestic network of service engineers and spare parts depots. This ensures that when you need on-site assistance, replacement parts, or emergency repairs, help can arrive promptly, minimizing costly production delays. Ask about their average response time and the availability of critical spare parts.

Furthermore, assess the depth of their technical support. This goes beyond basic installation and commissioning. The best suppliers provide thorough operator training, detailed maintenance manuals, and ongoing technical consultation. They may offer remote diagnostic services, allowing their experts to monitor machine performance and preemptively identify potential issues, thereby transitioning your maintenance strategy from reactive to predictive.

Finally, consider the supplier's commitment to long-term partnership. A reliable partner will provide software updates for control systems, offer retrofitting services for technology upgrades, and maintain open channels for technical queries. This enduring support ensures your internal mixer remains efficient and competitive for years, protecting your investment and enhancing your production capabilities.

3、Profiles of the Leading Chinese Suppliers

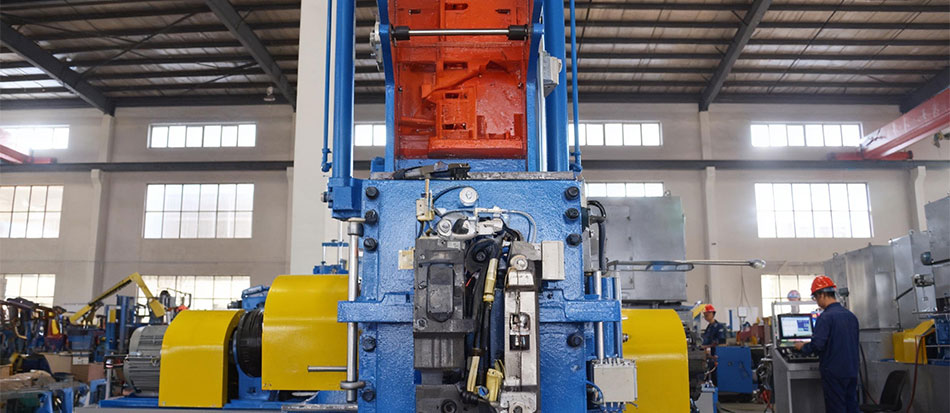

When you explore the profiles of the leading Chinese suppliers, you'll find a diverse group of companies, each with unique strengths. Among them, Qingdao Apex Machinery Technology Co., Ltd. (internationally branded as APEX) stands out. Founded in 2014, APEX is a high-tech enterprise specializing in the R&D, manufacturing, and sales of high-end rubber and plastic machinery. Their core business spans personal care and industrial monofilament extruders, high-precision medical/industrial tubing lines, rubber foaming and profile equipment, and PU/sponge CNC production lines. With a provincial engineering technology center and an intelligent production base, they are committed to providing advanced, energy-saving, and intelligent industrial solutions. Their equipment is widely used in electronics, medical, automotive, and construction industries, serving over a thousand leading clients globally. This makes APEX a benchmark for technological innovation and global competitiveness in the rubber machinery sector, offering you a reliable partner for sophisticated mixing needs.

Other top suppliers typically share similar commitments to innovation and quality. You will encounter manufacturers with decades of experience, boasting extensive R&D facilities and a strong focus on automation and energy efficiency. Their product portfolios often include various internal mixer models, from laboratory-scale units to large production machines, designed to meet different capacity and technical requirements. Understanding each company's specialization, such as APEX's focus on precision extrusion and foaming lines, helps you match their expertise with your specific application, whether it's for tire compounds, technical rubber goods, or other specialized products.

As you evaluate these leaders, consider their global footprint and after-sales service network. A supplier like APEX, with products exported to over 30 countries, demonstrates proven international acceptance and the capability to support your operations worldwide. This aspect is crucial for ensuring long-term operational reliability and access to technical support, spare parts, and service. By reviewing these detailed profiles, you can move beyond basic specifications and identify a partner whose technological vision, market experience, and customer commitment align perfectly with your production goals and quality standards.

3.1、Established Industry Giants with Full Product Lines

When you engage with the established industry giants in China's rubber internal mixer market, you are tapping into decades of accumulated expertise and a comprehensive ecosystem of machinery. These companies are not just equipment manufacturers; they are integrated solution providers. Their hallmark is a complete product line that covers everything from laboratory-scale mixers to massive production units, often complemented by downstream equipment like calenders, extruders, and vulcanizing presses. This allows you to source a coordinated production line from a single vendor, ensuring compatibility and simplifying technical support and spare parts management.

Their scale of operation translates into significant advantages for you. Massive R&D investments enable continuous innovation in rotor design, mixing chamber geometry, and control systems, leading to mixers that offer superior dispersion, shorter mixing cycles, and lower energy consumption. You benefit from proven, reliable technology that has been field-tested in countless applications worldwide. Furthermore, their global sales and service networks mean you can expect professional installation, training, and after-sales support, minimizing your operational downtime.

Procuring from these giants often involves dealing with a well-structured international business division accustomed to handling export documentation, customs clearance, and technical communication in multiple languages. While their machines may command a premium compared to smaller workshops, you are investing in long-term reliability, consistent quality, and the peace of mind that comes with a globally recognized brand. For large-scale, high-volume production where equipment uptime is critical, these suppliers represent a low-risk, high-value partnership.

3.2、Specialized Niche Players and Technology Innovators

When you look beyond the largest manufacturers, you'll find that specialized niche players and technology innovators are often the source of the most groundbreaking advancements in rubber internal mixer design. These companies typically focus on solving specific, high-value challenges in rubber compounding, such as ultra-precise temperature control, mixing for high-performance materials, or developing compact, energy-efficient models for specialized applications.

For your operation, engaging with these innovators can be particularly beneficial if you have unique material formulations or stringent process requirements that standard machines cannot meet. They excel in customization, working closely with you to adapt their core technologies—like advanced rotor geometries, novel sealing systems, or intelligent process control software—to your exact production needs. Their R&D is intensely focused, often leading to patents in mixing efficiency or batch consistency.

While their production volume might be smaller than industry giants, their impact is significant. You benefit from their agility and deep technical expertise. They are not just selling a machine; they are often providing a tailored process solution. This makes them ideal partners for manufacturers in sectors like aerospace, medical devices, or advanced electronics, where rubber compound specifications are exceptionally demanding.

Choosing to work with a specialized supplier requires a clear understanding of your own technical roadmap. You should evaluate their patent portfolio, case studies of similar challenging applications, and their capacity for collaborative engineering. The partnership is more intimate, and the success hinges on their ability to translate your process challenges into mechanical and control innovations that deliver superior compound quality and repeatability.

3.3、Rising Stars with Agile Manufacturing and Customization

When you look beyond the established giants, you'll find a dynamic group of suppliers that are making significant waves in the Chinese rubber internal mixer market. These rising stars distinguish themselves not by sheer volume but through agile manufacturing processes and a deep commitment to customization. They understand that your production needs are unique, and they are structured to respond quickly and effectively.

Their agility stems from leaner organizational structures and a focus on modular design principles. This allows them to adapt standard mixer models to your specific requirements—be it a special rotor configuration, a unique cooling system, or integration with your existing production line. For you, this means getting a machine that fits your process perfectly, rather than forcing your process to fit a standard machine.

These companies often invest heavily in advanced CNC machining centers and assembly technologies, enabling them to maintain high precision while handling smaller batch orders or bespoke projects. Their customer-centric approach means you work closely with their engineering team from the design phase through commissioning, ensuring every technical detail aligns with your expectations.

Furthermore, their after-sales service is typically highly responsive. Being more nimble, they can provide faster technical support, spare parts delivery, and on-site service. Partnering with such a supplier can be particularly advantageous if you operate in a niche segment, require frequent recipe changes, or are looking for a cost-effective yet highly tailored solution to gain a competitive edge.

3.4、Export-Oriented Suppliers with International Certifications

When you are sourcing rubber internal mixers from China for international markets, prioritizing suppliers with a strong export orientation and recognized international certifications is paramount. These manufacturers have structured their entire operation—from design and production to quality control and documentation—to meet the rigorous standards demanded by global clients. Their certifications, such as CE, ISO, and others specific to target regions, are not just badges on a website; they are a testament to a systemic commitment to safety, quality, and international compliance.

You will find that these export-oriented suppliers typically invest heavily in R&D to ensure their machines comply with the latest international technical and environmental directives. For instance, CE marking indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area. This means the machinery's electrical systems, safety guards, noise levels, and emissions are designed to pass stringent audits, giving you confidence during customs clearance and installation in your country.

Beyond certifications, their strength lies in their international business infrastructure. They often maintain multilingual sales and technical support teams, provide comprehensive English manuals and drawings, and are adept at handling international logistics, shipping, and after-sales service across different time zones. Their experience in dealing with diverse customer requirements makes the procurement process smoother for you, reducing risks associated with miscommunication and technical misunderstandings.

Choosing a supplier from this category ensures you receive a product built to world-class standards. It mitigates regulatory risks and often aligns with your own company's quality management systems. When evaluating these suppliers, you should verify the validity and scope of their certifications and ask for case studies or references from projects in your region or similar industries to assess their true export capability and global support network.

4、How to Choose the Right Supplier for Your Needs

After reviewing the top suppliers, the next critical step is selecting the right partner for your specific operations. Your choice should align with your production scale, material requirements, and long-term business goals. Consider not only the machine's specifications and price but also the supplier's technical support, customization capabilities, and after-sales service network. For instance, a company like APEX, which emphasizes R&D through its provincial engineering center and offers intelligent, energy-efficient solutions, demonstrates the value of technological partnership. You should evaluate if a supplier's core competencies, such as APEX's focus on high-precision medical/industrial tubing or rubber foaming equipment, match your application needs in sectors like healthcare or automotive.

Furthermore, assess the supplier's global experience and clientele. A proven track record of serving international markets and leading customers indicates reliability and adaptability to diverse standards. Verify their manufacturing quality control processes and commitment to innovation, as these factors directly impact machine performance and longevity. Ultimately, the right supplier should act as a strategic ally, providing not just a product but a comprehensive solution that enhances your productivity and competitive edge in the industry.

4.1、Matching Machine Specifications to Your Production Goals

When matching machine specifications to your production goals, you must first conduct a thorough analysis of your current and projected output. Consider the volume of rubber compound you need to produce per hour or per day. A supplier's internal mixer model, such as the Banbury-type mixer, comes in various chamber sizes (measured in liters) and power ratings. Selecting a machine with too small a capacity will bottleneck your production line, while an oversized machine leads to unnecessary capital expenditure and higher energy consumption.

Next, evaluate the technical specifications against the material characteristics you process. Different rubber compounds have varying viscosity, filler content, and shear sensitivity. You need to ensure the mixer's rotor design (e.g., tangential or intermeshing), speed ratio, and cooling efficiency are compatible with your recipes. Leading Chinese suppliers offer customization options; discussing your specific material requirements with their engineers is crucial to get a machine that delivers optimal dispersion and shorter mixing cycles.

Furthermore, align the machine's degree of automation with your operational strategy. Modern internal mixers can be equipped with automated weighing, feeding, and discharge systems, integrated with PLC control for recipe management and data recording. If your goal is to improve consistency, reduce manual error, and enable Industry 4.0 connectivity, prioritizing suppliers who provide advanced automation packages becomes a key decision factor.

Finally, consider the total cost of ownership, which goes beyond the initial purchase price. A machine perfectly matched to your specifications will operate efficiently, consume less energy per batch, and have lower long-term maintenance costs. Therefore, your dialogue with potential suppliers should focus on how their machine's specifications translate into tangible productivity gains, quality improvements, and return on investment for your specific production scenario.

4.2、Assessing Customization and Co-development Capabilities

When you assess a supplier's customization and co-development capabilities, you are essentially evaluating their ability to move beyond being a simple equipment vendor and become a true engineering partner. This is critical because your production process is unique, and an off-the-shelf internal mixer may not fully optimize your efficiency, product quality, or material usage. You need a supplier who can listen to your specific challenges and translate them into technical solutions.

Start by examining their R&D department's structure and history. Ask direct questions: Do they have a dedicated team for custom projects? Can they provide case studies or references where they successfully modified standard machine designs? A leading supplier will have a portfolio of bespoke projects, such as developing special rotor geometries for specific compound characteristics, integrating proprietary control systems, or creating machines for novel materials. Their engineers should be proactive in discussing your technical parameters rather than just quoting from a standard catalog.

Furthermore, the co-development process itself is a key indicator. A capable partner will engage in a collaborative dialogue, involving you in the design review stages. They should be transparent about the feasibility, timelines, and costs associated with customization. You should assess their willingness to conduct joint trials, either at their facility or yours, to test and refine the solution. This iterative approach minimizes risk and ensures the final equipment meets your exact operational goals.

Finally, consider the long-term implications. Customized machinery may require specialized spare parts and technical support. Verify that the supplier has the commitment and infrastructure to support the unique machine throughout its lifecycle. Their ability to co-develop is not just about the initial build but also about providing sustained engineering support, ensuring that your customized internal mixer remains a competitive asset for years to come.

4.3、Verifying Installation, Training, and Spare Parts Logistics

Verifying the supplier's logistical and technical support capabilities is a critical step that directly impacts your production continuity. You must confirm the details of their installation service, including whether they provide on-site engineers, the timeline for installation, and who bears the associated costs. A professional supplier will have a standardized procedure to ensure the internal mixer is correctly integrated into your production line, minimizing downtime.

Comprehensive operator training is non-negotiable for safety, efficiency, and machine longevity. You should inquire about the training curriculum, the qualifications of the trainers, and whether it's conducted on-site or at their facility. Effective training ensures your team can operate the equipment optimally and perform basic troubleshooting, which is a key factor in maximizing your return on investment.

Finally, a robust spare parts logistics system is your safeguard against prolonged production halts. You need to verify the supplier's parts inventory, their standard delivery lead times for critical components, and their policy on emergency orders. Establishing a clear agreement on spare parts availability and logistics before purchase is essential for maintaining your operational resilience and long-term partnership with the supplier.

4.4、Considering Long-Term Partnership and Upgrade Potential

When evaluating a supplier from the Top 10 list, you must look beyond the immediate purchase. A machine is a long-term capital investment, and its value is heavily influenced by the supplier's commitment to a lasting partnership. You should assess their willingness to support you through future technological upgrades, capacity expansions, and evolving process requirements. A forward-thinking supplier views each sale as the beginning of a collaborative journey, not the end of a transaction.

Examine the supplier's track record in providing upgrade paths for their existing machinery. Can the internal mixer be retrofitted with new control systems, enhanced rotors, or energy-saving features years down the line? This upgrade potential protects your initial investment and ensures your production line remains competitive without requiring a complete, costly replacement. Ask for specific case studies where they have successfully upgraded older models for clients.

Furthermore, consider the supplier's own R&D roadmap. A company that continuously innovates and releases new generations of equipment is more likely to offer compatible and advanced upgrade solutions. Their technological trajectory should align with your industry's future demands, such as trends towards automation, data integration (Industry 4.0), and sustainable manufacturing. Partnering with such a supplier future-proofs your operations.

Finally, the quality of after-sales service, availability of genuine spare parts over the machine's entire lifecycle, and the provision of ongoing technical training are critical indicators of a supplier's partnership ethos. A reliable partner will proactively communicate about improvements and offer service contracts that ensure your mixer's longevity and optimal performance, thereby maximizing your return on investment and fostering mutual growth.

Selecting the right partner from the top 10 suppliers of rubber internal mixers in China is a strategic decision that impacts your production efficiency, product quality, and overall competitiveness. We hope this detailed guide has provided you with valuable insights and a clearer path forward in your sourcing journey. Remember to consider not just the machine specifications, but also the supplier's commitment to innovation, customization, and ongoing support.

Building a successful partnership requires alignment in values and goals. The leading suppliers highlighted here have demonstrated their ability to adapt to diverse industry demands and deliver solutions that drive real value. As you move forward, engage with potential suppliers, ask detailed questions, and request references to ensure a perfect fit for your operational requirements.

Among the innovative leaders in this field is Qingdao Apex Machinery Technology Co., Ltd. (International Brand: APEX). Founded in 2014, Apex is a high-tech enterprise specializing in the R&D, manufacturing, and sales of high-end rubber and plastic machinery. Their core business spans personal care and industrial monofilament extruders, high-precision medical/industrial tubing lines, rubber foaming and profile equipment, and PU/sponge CNC production lines. Leveraging a provincial engineering center and an intelligent production base, Apex is dedicated to providing advanced, energy-efficient, and smart industrial solutions. Their products are widely used in electronics, healthcare, automotive, and construction industries, serving over a thousand leading clients across more than 30 countries. Apex stands as a robust benchmark in the rubber machinery sector, renowned for its technological innovation and global competitiveness.