Price of Small Rubber Internal Mixer for Laboratory Use: Your Complete Guide to Cost & Selection

Price of small rubber internal mixer for laboratory use is a critical factor when you're setting up or upgrading your R&D or quality control lab. You need reliable equipment that fits your budget without compromising on performance for your material testing and small-batch production.

Understanding what influences the cost helps you make an informed investment. It's not just about the initial purchase price; it's about finding a mixer that delivers precision, durability, and value for your specific applications.

This guide will break down everything you need to know about the pricing, key features, and selection criteria for laboratory internal mixers, empowering you to choose the best option for your needs.

1、Key Factors Influencing the Price of Lab Internal Mixers

1.1、Mixer Capacity and Chamber Size

1.2、Heating System and Temperature Control Precision

1.3、Drive System Power and Mixing Intensity

1.4、Brand Reputation and Technical Support

2、Typical Price Range and What to Expect

2.1、Entry-Level/Basic Models

2.2、Mid-Range Standard Models

2.3、High-End Precision Models

3、Essential Features to Justify Your Investment

3.1、User-Friendly Control Interface

3.2、Robust Construction and Easy Maintenance

3.3、Safety Features and Compliance

3.4、Data Recording and Connectivity Options

4、Smart Tips for Budgeting and Purchasing

4.1、Clearly Define Your Application Requirements

4.2、Evaluate Total Cost of Ownership (TCO)

4.3、Request Demos and Compare Quotes

4.4、Check Warranty and After-Sales Service

1、Key Factors Influencing the Price of Lab Internal Mixers

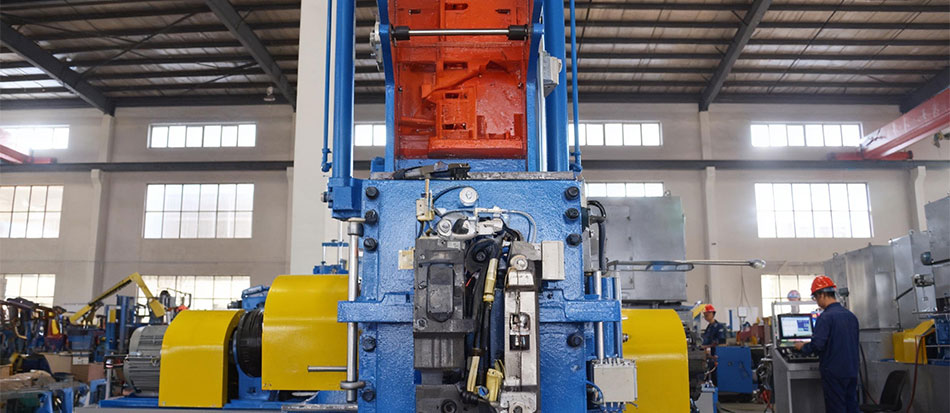

When you're evaluating the price of a small rubber internal mixer for your laboratory, several key factors come into play, directly impacting your investment. First, the mixer's capacity and size are primary cost drivers; a 1-liter lab mixer will naturally cost less than a 5-liter model. The core of the price, however, lies in the engineering and material quality. Mixers from manufacturers like APEX, which invest in advanced R&D and use high-grade components for the mixing chamber, rotors, and seals, command a higher price due to their superior durability, precision, and consistent performance for critical R&D and quality control tasks.

Secondly, the level of automation and control sophistication significantly influences cost. A basic manual machine is more affordable, but a mixer with a programmable logic controller (PLC), touchscreen interface, precise temperature control, and data logging capabilities—features that enhance repeatability and efficiency—will be priced higher. For a company like APEX, integrating such intelligent, energy-saving solutions is a hallmark, justifying the value. Finally, brand reputation, after-sales service, and customization options (like specific rotor designs for your material) also contribute to the final price, ensuring you get a reliable system tailored to your lab's exact needs rather than just a generic piece of equipment.

1.1、Mixer Capacity and Chamber Size

The capacity of a laboratory internal mixer, typically measured by the total chamber volume in liters or cubic centimeters (cc), is the single most direct factor determining its price. You'll find common models ranging from as small as 1-2 liters for ultra-precise micro-compounding up to 10 liters or more for larger pilot-scale batches. As a rule, a larger chamber requires more robust construction, a more powerful drive motor, and heavier-duty components, all of which increase the manufacturing cost and, consequently, the purchase price.

Your choice of capacity must be driven by your typical batch size. Using a mixer that is too large for your small samples can lead to poor material dispersion and inaccurate test results because the mixing elements cannot properly engage the material. Conversely, consistently overfilling a small mixer can strain the motor and bearings. Therefore, selecting the right size for your application is crucial for both performance and cost-effectiveness.

Beyond the nominal volume, consider the working volume, which is usually 50-70% of the total chamber capacity. A 3-liter mixer, for example, might have an optimal working batch of 1.5 to 2 liters. Manufacturers price their mixers based on the total chamber size, so you pay for the maximum potential capacity. Aligning your standard batch requirements with the mixer's working volume ensures you get the performance you need without paying for unused overhead.

1.2、Heating System and Temperature Control Precision

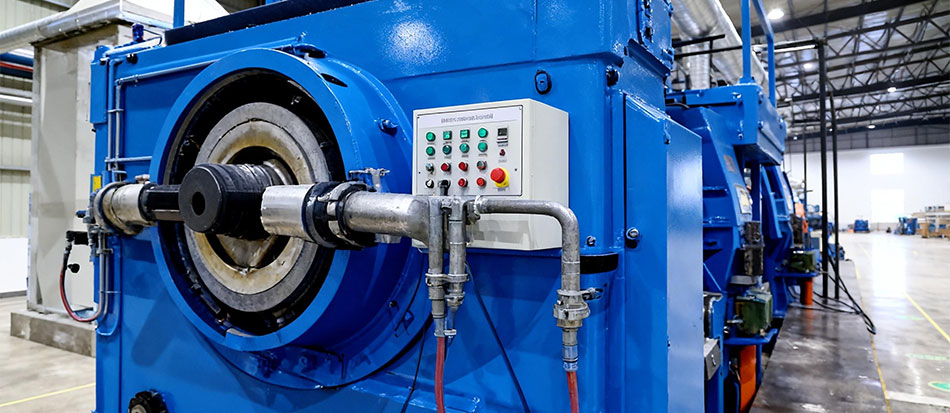

The heating system is a major cost driver in a laboratory internal mixer. You'll typically encounter two main types: electric heating and oil heating (or thermal oil heating). Electric heating systems are generally less expensive upfront and offer faster heat-up times, which is ideal for rapid testing cycles. However, for applications requiring extremely stable and uniform temperature control across a wide range (e.g., above 200°C), oil circulation systems are superior. They provide excellent temperature homogeneity throughout the mixing chamber, but this precision and complexity come at a higher price.

Temperature control precision directly impacts your experimental repeatability and data accuracy. A basic on/off controller is inexpensive but can lead to significant temperature fluctuations (±5°C or more). For rigorous R&D work, you need a PID (Proportional-Integral-Derivative) controller. A high-quality PID system can maintain temperature within ±1°C or even tighter tolerances. The more sophisticated the control algorithm and sensor technology, the higher the cost, but it's a non-negotiable investment for reliable formulation development and quality assurance testing.

The integration of the heating system with the mixer's software also affects price. Advanced models offer programmable temperature profiles, allowing you to simulate specific production curing cycles or multi-stage mixing processes. This programmability adds significant value for complex testing but increases the initial investment. When evaluating cost, consider whether your work requires simple set-point control or the ability to run intricate, automated temperature-time recipes.

1.3、Drive System Power and Mixing Intensity

The drive system is the heart of your lab internal mixer, directly dictating its mixing intensity and capability. You must match the motor power and torque to the materials you plan to process. A higher-power drive system can handle higher-viscosity compounds, fill more material, and achieve a faster, more uniform dispersion of fillers like carbon black or silica.

This increased capability comes at a cost. Mixers with more powerful AC or servo motors, robust gearboxes, and precision speed control are inherently more expensive. However, this investment is crucial if your work involves tough, high-load formulations. An underpowered mixer will struggle, leading to poor mixing quality, excessive wear, and ultimately, unreliable data.

Consider the mixing intensity you need. For gentle blending of pre-mixed masterbatches, a standard drive may suffice. But for intensive development work where you simulate production-scale shear forces, you need a drive system powerful enough to generate the necessary shear stress and temperature rise within the chamber, which is a key factor in compound development.

1.4、Brand Reputation and Technical Support

When you evaluate the price of a laboratory internal mixer, the brand behind the machine is a significant, albeit sometimes intangible, cost component. Established brands with a long history in rubber and polymer processing equipment command a premium. You are not just paying for a name; you are investing in decades of accumulated engineering expertise, proven reliability, and a track record of performance that reduces your technical risk.

This reputation is often built on superior materials, precision manufacturing, and rigorous quality control standards. A mixer from a reputable manufacturer is more likely to deliver consistent batch-to-batch results, have longer service intervals, and experience fewer unexpected breakdowns. For your lab, where data accuracy and repeatability are paramount, this reliability directly translates to value, justifying a higher initial price point.

Technical support is the critical companion to brand reputation and is explicitly factored into the total cost of ownership. Comprehensive support includes detailed installation guidance, thorough operator training, and readily available spare parts. Consider the cost and downtime if a critical component fails and you must wait weeks for a generic part versus having it shipped overnight from the manufacturer's stock.

Furthermore, access to expert application engineers can be invaluable. They can help you optimize mixing parameters for your specific compounds, troubleshoot processing issues, and ensure you get the most out of your investment. A cheaper, no-name mixer might save you money upfront but could cost you far more in lost productivity, failed experiments, and expensive third-party repair services down the line.

Therefore, when comparing prices, you must assess the value of the support ecosystem. A slightly higher price from a vendor with a strong local service network and responsive technical team often provides better long-term economics and peace of mind than the lowest-priced option with minimal support.

2、Typical Price Range and What to Expect

When you start researching the price of a small rubber internal mixer for laboratory use, you'll find a broad range, typically from around $5,000 to over $30,000. This significant variation is not arbitrary; it directly reflects the machine's capabilities, build quality, and the technological sophistication behind it. For basic models suitable for simple mixing tasks, you can expect to invest at the lower end of this spectrum. However, if your R&D work demands precise temperature control, advanced data acquisition, high-torque mixing for challenging compounds, or specific safety features, the price will understandably be higher. Companies like APEX, which integrate advanced R&D from a provincial engineering center into their manufacturing, often position their lab mixers in the mid to upper price range. This investment translates into superior precision, durability, and intelligent features that ensure repeatable results and long-term reliability for your critical testing and small-batch production needs.

2.1、Entry-Level/Basic Models

Entry-level or basic models of small rubber internal mixers are designed for laboratories with fundamental mixing needs and tight budget constraints. You can typically expect these mixers to fall within a price range of approximately $5,000 to $15,000 USD. The exact figure depends heavily on the manufacturer's origin, brand recognition, and the specific configuration you choose.

At this price point, you are investing in core functionality. These mixers will perform essential mixing tasks for compound development, quality checks, or student training. They usually feature a simple, robust mechanical design with manual controls for temperature, rotor speed, and mixing time. The chamber volume is often on the smaller side, commonly between 1 to 5 liters, which is ideal for creating test batches of 50 to 500 grams.

It's crucial to understand the trade-offs. To achieve this lower cost, manufacturers may use more standard-grade materials for components not in direct contact with the compound. The temperature control system might be less precise, and the data recording capabilities are often minimal or non-existent. You might need to rely on external instruments for detailed process monitoring.

Your primary considerations when evaluating an entry-level model should be: Is the mixing chamber volume suitable for your typical batch size? Does it reach the necessary temperature and shear rates for your materials? And most importantly, is the build quality reliable enough to ensure consistent results and minimal downtime? While these models are cost-effective, prioritizing a reputable supplier with good technical support is essential to protect your investment.

2.2、Mid-Range Standard Models

Mid-range standard models represent the sweet spot for most laboratory applications, offering a robust balance between cost and capability. You can expect to invest between $15,000 and $35,000 for these units. This price bracket delivers significant upgrades over entry-level mixers, primarily in terms of construction quality, control precision, and durability. The mixers in this range are designed for consistent, reliable performance in demanding R&D and QC environments.

For your money, you typically get a mixer with a more powerful and efficient drive system, often featuring a variable frequency drive (VFD) for better speed control and energy management. The mixing chamber and rotors are usually constructed from higher-grade, hardened steel or specialized alloys, offering superior wear resistance and a longer operational life. This directly impacts your long-term cost of ownership by reducing maintenance and replacement part frequency.

Control systems in this tier are a major differentiator. You will find digital temperature controllers for precise heating and cooling of the chamber, and programmable logic controllers (PLCs) that allow you to save and repeat complex mixing sequences. This level of automation ensures batch-to-batch consistency, which is crucial for your experimental reproducibility and quality assurance protocols. Data recording capabilities for parameters like torque, temperature, and time are also common.

These models often come with enhanced safety features, such as interlocked safety guards, emergency stop buttons, and overload protection for the motor. They are built to handle a wider range of material viscosities and formulations more effectively than basic models. When selecting a mid-range mixer, pay close attention to the manufacturer's reputation for technical support, availability of spare parts, and the comprehensiveness of the warranty, as these factors contribute significantly to the overall value of your investment.

2.3、High-End Precision Models

When your research demands the utmost in control, repeatability, and data integrity, high-end precision laboratory internal mixers are the definitive choice. These models are engineered for advanced R&D, formulation development, and critical quality assurance tasks where even minor process variations are unacceptable. You are investing not just in a mixer, but in a sophisticated process simulation and data acquisition system.

The price for these top-tier units typically starts around $25,000 and can easily exceed $50,000, depending on configuration and optional features. This premium cost is justified by their exceptional build quality, often featuring hardened or stainless-steel mixing chambers and rotors, ultra-precise temperature control systems (liquid heating/cooling with PID accuracy), and robust, low-backlash drives. The core value lies in their advanced instrumentation and software integration.

You will benefit from features like fully computerized control systems that allow you to program complex mixing sequences, including precise ram force profiles, rotor speed curves, and temperature ramps. Real-time data logging of torque, temperature, pressure, and energy input is standard, providing you with a complete rheological fingerprint of your compound. This data is crucial for scaling up to production or for patent-related documentation.

Furthermore, high-end models often offer superior safety interlocks, easier cleaning mechanisms to prevent cross-contamination, and compatibility with various auxiliary equipment like strip-off knives and pelletizers. The investment secures long-term reliability, minimal downtime, and the confidence that your experimental results are accurate and reproducible, ultimately saving you time and cost in the development cycle.

3、Essential Features to Justify Your Investment

When evaluating the price of a small rubber internal mixer for your lab, it's crucial to look beyond the initial cost and focus on features that deliver long-term value and justify your investment. You need a machine that ensures precise, repeatable results for your R&D and quality control. Key features to prioritize include precise temperature control for consistent material properties, robust construction with durable rotors and mixing chamber for longevity, user-friendly controls for efficient operation, and easy cleaning capabilities to prevent cross-contamination between batches. For companies like APEX, which specializes in advanced, intelligent solutions, these features are engineered to enhance your lab's productivity and data reliability, making the higher initial investment worthwhile through reduced downtime and superior performance.

3.1、User-Friendly Control Interface

A user-friendly control interface is not a luxury; it's a fundamental requirement for efficient and accurate laboratory work. When you're operating a small rubber internal mixer, the control system is your primary point of interaction. A well-designed interface, often featuring a touchscreen HMI (Human-Machine Interface), allows you to program complex mixing sequences, set precise temperature profiles, and monitor key parameters like torque, speed, and energy input in real-time with minimal effort.

This intuitive control directly impacts your productivity and data integrity. You can save and recall recipes for different compounds, ensuring batch-to-batch consistency. Clear visualizations of process curves help you analyze the mixing behavior and identify any anomalies immediately. The time you save on setup and troubleshooting translates directly into cost savings and faster project turnaround.

Furthermore, a modern interface simplifies training and reduces operator error. New technicians can become proficient quickly because the workflow is logical and guided. Advanced models may offer connectivity options for data export, enabling seamless integration with your Laboratory Information Management System (LIMS) for comprehensive traceability and reporting, which is crucial for quality assurance and R&D documentation.

3.2、Robust Construction and Easy Maintenance

When you invest in a small rubber internal mixer for your lab, you're not just buying a machine; you're buying years of reliable service. A robust construction is the foundation of this longevity. Look for a mixer with a heavy-duty frame, high-grade alloy steel mixing chamber, and rotors engineered to withstand the high shear forces and pressures of compounding. This durability directly translates to consistent mixing performance, batch after batch, without the risk of contamination from worn parts or the downtime of frequent repairs.

Easy maintenance is the practical partner to robust construction. A well-designed laboratory mixer should allow for straightforward disassembly and cleaning. Features like a swing-out mixing chamber or a drop-down design are invaluable, giving you full access to clean every surface thoroughly between formulations. Similarly, seals and bearings should be easily accessible for inspection and replacement. This minimizes cross-contamination risks and ensures your research data remains accurate and reproducible.

Consider the long-term cost of ownership. A cheaper mixer with a flimsy build will likely cost you more in repairs, parts replacement, and lost productivity due to unexpected breakdowns. Conversely, a mixer built with durability and serviceability in mind, while perhaps commanding a higher initial price, protects your investment. It ensures your lab operations run smoothly, safeguarding your research timelines and ultimately providing a better return on your capital expenditure.

3.3、Safety Features and Compliance

When evaluating the price of a small rubber internal mixer for laboratory use, you must scrutinize the safety features and compliance standards it meets. This is not an area for compromise. A machine lacking proper safety engineering can lead to catastrophic accidents, costly downtime, and severe legal liabilities. Your investment must prioritize protecting your personnel and your facility.

Look for robust mechanical safety interlocks on the mixing chamber door. These should physically prevent the rotors from operating when the chamber is open and vice-versa, eliminating the risk of crushing or shearing injuries. An emergency stop system, with clearly marked and easily accessible buttons, is a fundamental requirement to halt all machine functions instantly in case of an anomaly.

Electrical safety and compliance with international standards (such as CE, UL, or others relevant to your region) are non-negotiable. This certification indicates the mixer has been designed and tested to meet stringent electrical safety, electromagnetic compatibility, and machine directive requirements. It safeguards against electrical hazards and ensures the equipment can be safely integrated into your lab environment.

Consider features like overload protection for the motor and drive system. This prevents damage to the machine from overloading the mixing chamber and protects the motor from burnout. Furthermore, a well-designed machine will have guarding around all moving parts like the rotors, drive belts, and gears to prevent accidental contact during operation or maintenance.

Ultimately, the cost associated with these integrated safety features and certification processes is a direct investment in risk mitigation. A slightly higher initial price for a fully compliant, safety-engineered mixer is far more economical than the potential costs of an accident, equipment damage, or non-compliance penalties. Your choice should reflect a commitment to creating a safe and professional laboratory workspace.

3.4、Data Recording and Connectivity Options

Data recording and connectivity are no longer just convenient extras; they are fundamental features that transform your small rubber internal mixer from a simple mixing device into a powerful process analysis tool. When you invest in a mixer with robust data capabilities, you are investing in traceability, repeatability, and deeper insights into your material behavior.

Look for a system that automatically records critical parameters like temperature, rotor speed, torque, and mixing time in real-time. This creates an immutable digital record for each batch, which is essential for quality control documentation, troubleshooting, and reproducing successful formulations. You eliminate manual transcription errors and gain a complete historical view of your mixing processes.

Modern connectivity options, such as USB export, Ethernet, or even Wi-Fi, allow you to seamlessly transfer this data to a laboratory computer or network. This enables you to use specialized software for in-depth analysis, generate reports, and integrate mixing data with other test results from your TGA, DSC, or rheometer, building a comprehensive material profile.

For advanced applications, some mixers offer software with programmable mixing stages and recipe management. You can save optimal mixing procedures (speed, temperature ramps, fill factor) and load them for future batches, ensuring absolute consistency. This level of control and documentation directly justifies a higher initial price by significantly reducing experimental variability and accelerating your R&D cycle.

4、Smart Tips for Budgeting and Purchasing

When budgeting for a small rubber internal mixer for your lab, start by clearly defining your technical requirements like mixing volume, temperature range, and control precision. This prevents overspending on unnecessary features. Consider the total cost of ownership, including energy consumption, maintenance, and potential downtime. Partnering with a specialized manufacturer like APEX (Qingdao Apex Machinery Technology Co., Ltd.) can be strategic. As a high-tech enterprise with a provincial engineering center, APEX offers advanced and energy-efficient solutions. Their expertise in rubber equipment ensures you get a reliable mixer with intelligent features that enhance R&D accuracy, providing long-term value and reducing hidden costs over the machine's lifecycle.

Request detailed quotations that break down costs for the mixer, standard accessories, and optional extras. Don't hesitate to ask about after-sales service, warranty, and technical support availability, which are crucial for lab continuity. Explore financing or leasing options if upfront capital is limited. Finally, validate your choice by reviewing case studies or contacting existing clients, especially those in similar industries like automotive or medical parts R&D, to gauge real-world performance and the supplier's reliability before finalizing your purchase.

4.1、Clearly Define Your Application Requirements

Start by asking yourself: what materials will you be mixing? The specific type of rubber compound (e.g., natural rubber, SBR, silicone, fluoroelastomer) and its formulation (fillers, oils, curatives) directly dictate the mixer's required specifications. High-viscosity or filled compounds demand more powerful motors and robust rotors.

Next, determine your typical batch size. A "small" lab mixer can range from 1-3 liters down to just 50-100 grams of chamber volume. Purchasing a mixer with a chamber much larger than your needs wastes energy and material, while one too small forces you to run excessive batches, skewing data and increasing time.

Consider your process parameters. Do you need precise temperature control for sensitive curing studies? Will you be conducting mastication, mixing, or viscosity testing? The required features—like heating/cooling systems, variable speed drives, programmable logic controllers (PLC), and data logging capabilities—significantly impact the price.

Finally, think about throughput and future needs. Is this for occasional R&D or continuous quality control? Planning for slight scalability can be a cost-effective strategy, preventing the need for another purchase soon. Clearly documenting these requirements creates a vital checklist for comparing models and avoiding over- or under-specification.

4.2、Evaluate Total Cost of Ownership (TCO)

When you consider the price of a small rubber internal mixer for laboratory use, looking beyond the initial purchase price is crucial. The Total Cost of Ownership (TCO) is the real metric for evaluating your investment. It encompasses all expenses associated with the mixer over its entire operational lifespan, giving you a clearer picture of long-term value versus short-term savings.

Your TCO calculation should start with the purchase price but must also include installation costs, which might involve electrical work or minor facility modifications. Next, factor in the ongoing energy consumption of the mixer; a more energy-efficient model, even if slightly more expensive upfront, can lead to significant savings on your utility bills over years of operation.

Maintenance and spare parts form another critical component. Inquire about the cost and availability of common wear parts like seals, rotors, and mixing chamber liners. A mixer with a robust design and readily available, reasonably priced consumables will have a lower TCO. Also, consider the potential cost of downtime; a reliable machine from a reputable supplier with good technical support minimizes production or research delays.

Finally, don't overlook the end-of-life costs or potential resale value. A well-built, durable laboratory internal mixer from a trusted brand often retains better residual value. By evaluating TCO, you shift your focus from finding the cheapest option to identifying the most cost-effective and reliable partner for your laboratory's rubber mixing needs.

4.3、Request Demos and Compare Quotes

Requesting a live demonstration is a non-negotiable step in your purchasing process. A demo allows you to see the machine in action, assess its build quality, noise level, and ease of operation firsthand. You can test it with your own rubber compound or a similar material to evaluate its mixing efficiency, temperature control accuracy, and discharge consistency. This practical experience is invaluable and often reveals nuances that specifications sheets cannot convey.

When you receive quotes from different suppliers, do not compare them based on price alone. Create a detailed comparison matrix. List each model's technical specifications, included standard accessories, warranty terms, delivery time, and after-sales service support. A slightly higher initial quote might include essential extras like spare rotors, temperature sensors, or a more comprehensive warranty, offering better long-term value.

Engage with the sales engineers during this phase. Ask pointed questions about maintenance requirements, common wear parts, and their availability. Inquire about software updates for PC-controlled models and training provisions. Their responsiveness and technical depth are strong indicators of the supplier's reliability and the quality of support you can expect post-purchase.

Finally, synthesize the information from your demos and quotes. Consider the total cost of ownership, which includes the purchase price, estimated maintenance, potential downtime, and the mixer's expected lifespan for your specific workload. The goal is to select the equipment that provides the optimal balance of performance, durability, and support, ensuring your laboratory's productivity and your investment's security.

4.4、Check Warranty and After-Sales Service

When evaluating the price of a small rubber internal mixer for laboratory use, you must look beyond the initial quote. The warranty terms and the quality of after-sales service are integral components of the total cost of ownership. A machine with a slightly higher upfront cost but a comprehensive warranty and robust support network can be far more economical in the long run than a cheaper alternative with limited coverage.

Start by scrutinizing the warranty period and what it explicitly covers. A standard warranty should protect you against manufacturing defects in critical components like the mixing chamber, rotors, bearings, and the drive system for at least one year. Pay close attention to what is excluded—wear parts like seals or gaskets might have shorter coverage. A longer warranty period often reflects the manufacturer's confidence in their product's durability and can save you significant repair costs.

Next, investigate the after-sales service structure. You need to know: Is there a local or regional service technician? What are the typical response times for technical support? Are spare parts readily available and reasonably priced? A supplier with a dedicated service team can minimize your lab's downtime if an issue arises, ensuring your research or production schedule stays on track. The ability to quickly source genuine parts is crucial for maintaining the mixer's precision and performance.

Finally, consider the availability of training and ongoing support. A good supplier will offer installation guidance, operational training, and access to technical documentation. This support helps you and your team use the equipment correctly and safely, preventing operator errors that could lead to costly damage not covered by warranty. This layer of service adds immense value to your investment, safeguarding both your budget and your research integrity.

Ultimately, the price of small rubber internal mixer for laboratory use should be viewed as an investment in your lab's capability and efficiency. By carefully weighing the factors discussed, you can select a mixer that offers the perfect balance of cost, performance, and long-term reliability for your research and development work.

Remember, the right equipment enhances your material testing accuracy and accelerates your innovation cycle. Prioritize quality and support to ensure your mixer serves your laboratory effectively for years to come.

When seeking advanced, intelligent solutions, consider partners with proven expertise. Apex Machinery, a high-tech enterprise specializing in R&D and manufacturing of premium rubber and plastic machinery, offers robust and innovative equipment. With a provincial engineering center and a smart production base, Apex provides advanced, energy-saving solutions trusted by leading clients in over 30 countries, making it a strong contender for your laboratory mixing needs.