High Tenacity PP/PE Monofilament Extruder for Fishing Nets: Your Ultimate Solution for Durable and Efficient Net Production

High tenacity PP/PE monofilament extruder for fishing nets is the cornerstone of modern, reliable fishing gear manufacturing. When you're in the business of producing fishing nets, the strength, durability, and consistency of the monofilament are non-negotiable. That's where choosing the right extrusion technology makes all the difference.

You need equipment that can transform polypropylene (PP) or polyethylene (PE) resins into ultra-strong, uniform filaments capable of withstanding harsh marine environments. This isn't just about making thread; it's about creating the backbone of nets that fishermen depend on for their livelihood and safety.

In this guide, we'll explore how a specialized high-tenacity monofilament extruder empowers your production line, enhances product quality, and ultimately boosts your competitiveness in the global market. Let's dive into the technology that sets superior fishing nets apart.

1、Why High Tenacity Monofilament is Critical for Modern Fishing Nets

1.1、Unmatched Strength and Abrasion Resistance

1.2、Superior Knot Stability and Net Shape Retention

1.3、Enhanced Resistance to UV Rays and Saltwater

1.4、Longer Lifespan and Reduced Replacement Costs

2、Core Technologies in a High-Performance PP/PE Monofilament Extruder

2.1、Precision Screw and Barrel Design for Optimal Polymer Processing

2.2、Advanced Spinline and Quenching System for Consistent Diameter

2.3、Multi-Stage Godet Units for Precise Drawing and Orientation

2.4、Integrated Heat Setting for Permanent Tenacity and Low Shrinkage

3、Key Benefits of Upgrading to a Specialized Extrusion Line

3.1、Significantly Higher Production Output and Yield

3.2、Consistent Filament Quality with Minimal Variation

3.3、Reduced Material Waste and Energy Consumption

3.4、Flexibility to Process Various PP/PE Grades and Additives

4、How to Choose the Right Extruder for Your Fishing Net Business

4.1、Assessing Your Target Filament Denier and Tenacity Requirements

4.2、Evaluating Production Capacity and Line Speed Needs

4.3、Importance of Automation and Ease of Operation

4.4、Considering Supplier Expertise and After-Sales Support

1、Why High Tenacity Monofilament is Critical for Modern Fishing Nets

Imagine you are a fisherman battling a powerful catch in rough seas. The last thing you want is your net failing. This is precisely why high tenacity monofilament is non-negotiable for modern fishing nets. For you as a manufacturer, it translates directly into product reliability and market trust. High tenacity means the filament has superior tensile strength and resistance to elongation under load, ensuring nets don't easily snap or deform. This durability is crucial for withstanding abrasion against rocks, constant UV exposure, and the corrosive saltwater environment. By using a specialized extruder like those engineered by APEX, you can consistently produce PP/PE monofilament with this enhanced molecular orientation and strength. It allows you to create nets that are not only stronger and safer for end-users but also potentially lighter and longer-lasting, reducing replacement frequency and offering a significant competitive edge. In essence, investing in the right extrusion technology for high tenacity monofilament is investing in the core value and performance of your final product.

1.1、Unmatched Strength and Abrasion Resistance

When you produce fishing nets, the monofilament's ability to resist breaking and wear is paramount. High tenacity PP/PE monofilament extruders are engineered specifically to impart this critical property. The extrusion process precisely controls molecular orientation and crystallization, resulting in a filament with a significantly higher tensile strength than standard monofilament. This means the nets you manufacture can handle the immense stress of hauling heavy catches without snapping.

Furthermore, abrasion resistance is not a secondary feature; it's a core requirement. Nets constantly rub against rough surfaces—ocean floors, boat hulls, and even the catch itself. A standard filament would fray and weaken quickly, leading to frequent repairs or total failure. The high-tenacity filament produced by this specialized extruder has a denser, more uniform surface structure that dramatically slows down wear and tear, ensuring your nets maintain their integrity over countless fishing cycles.

This combination of strength and abrasion resistance directly translates to value for your end-users. Fishermen gain a reliable tool that reduces downtime, minimizes the risk of losing valuable catches due to net failure, and ultimately provides a better return on investment. By investing in the right extruder, you are not just selling a net; you are providing a durable, trustworthy asset for a demanding profession.

1.2、Superior Knot Stability and Net Shape Retention

When you produce monofilament with a high-tenacity extruder, you're not just increasing tensile strength; you're fundamentally engineering the material's memory and surface characteristics. This directly translates to superior knot stability. The filament's high orientation and consistent diameter ensure that when knots are tied—whether by hand or machine—they cinch down tightly and uniformly without slipping or cutting into themselves. This creates a secure, reliable joint that maintains its integrity under the dynamic, cyclic loads experienced during fishing operations.

For net shape retention, the role of your extruder is paramount. A high-tenacity monofilament possesses low creep and high elastic recovery. This means the net, once formed, resists permanent deformation from constant tension, the weight of the catch, or ocean currents. It springs back to its intended shape, preventing the mesh from becoming distorted or baggy. A net that loses its shape is inefficient; it can lead to poor fish capture rates, increased drag, and accelerated wear as filaments rub unevenly.

Your choice of extrusion technology directly influences these properties. Precise temperature control, optimized drawing ratios, and advanced quenching systems in a dedicated high-tenacity PP/PE extruder create a monofilament with a perfect balance of stiffness and flexibility. This balance is critical: the filament must be stiff enough to hold a knot and maintain mesh geometry, yet flexible enough to allow the net to be handled, set, and retrieved without becoming brittle or prone to kinking.

Ultimately, investing in the right extruder for high-tenacity monofilament gives your fishing nets a structural advantage. You deliver a product where every knot is a point of strength, not weakness, and where the net's design geometry is preserved throughout its service life. This reliability builds trust with fishermen, reduces the frequency of net repairs, and enhances the overall efficiency and safety of their fishing activities.

1.3、Enhanced Resistance to UV Rays and Saltwater

When you produce fishing nets, the monofilament's ability to withstand prolonged exposure to sunlight and seawater is not just an added feature; it's a fundamental requirement for product longevity. Ordinary filaments degrade quickly under UV radiation, becoming brittle and losing their tensile strength. A high-tenacity PP/PE monofilament extruder is engineered to process polymers with specialized UV stabilizers and antioxidants directly into the filament structure during extrusion.

This integrated manufacturing process ensures that the protective additives are uniformly distributed throughout the entire length of the monofilament, not just coated on the surface. As a result, the nets you produce offer superior resistance to photo-oxidative degradation caused by the sun's rays, maintaining their flexibility and strength season after season.

Similarly, saltwater is a highly corrosive environment that can accelerate material breakdown. The extruder's precise control over the polymer crystallization and orientation during drawing creates a denser, less permeable molecular structure. This inherent density makes the filament highly resistant to saltwater absorption, preventing swelling, loss of strength, and the growth of marine organisms that can add weight and cause damage.

Ultimately, by utilizing this advanced extrusion technology, you are not just making a net; you are engineering a durable tool. You provide your customers with gear that resists the two most aggressive elements at sea—sun and salt—ensuring their nets remain reliable, require less frequent replacement, and deliver a better return on investment over their extended service life.

1.4、Longer Lifespan and Reduced Replacement Costs

When you invest in a high-tenacity PP/PE monofilament extruder, you are fundamentally engineering a longer operational lifespan into every meter of netting you produce. The superior tensile strength and resistance to abrasion, UV degradation, and chemical attack from saltwater directly translate to nets that do not fray, weaken, or become brittle as quickly as those made from standard filaments.

This extended durability means your end-users—the fishermen—face far fewer operational disruptions. They spend less time repairing or replacing torn nets and more time actively fishing. For you as a manufacturer, this is a powerful value proposition: you are selling not just a net, but reduced downtime and higher profitability for your customer's business.

The economic impact is clear. A net that lasts twice as long effectively halves the replacement cost over its service life. This drastically lowers the total cost of ownership for the fisherman, making your product a more compelling and cost-effective choice in a competitive market. Your reputation for reliability grows with every season a net remains in service.

Furthermore, by producing longer-lasting nets, you contribute to sustainability. Fewer nets need to be manufactured, transported, and eventually disposed of, reducing the overall environmental footprint of the fishing industry. This longevity, enabled by your advanced extrusion process, becomes a key selling point that aligns with both economic and ecological priorities.

2、Core Technologies in a High-Performance PP/PE Monofilament Extruder

At the heart of a high-performance PP/PE monofilament extruder lies a suite of core technologies that directly determine the tenacity and consistency you achieve. For you, this means precise control over every stage, from raw material feeding to final filament winding. Advanced screw design and multi-zone temperature control ensure optimal polymer melting and homogenization, which is critical for developing the high molecular orientation that gives the filament its exceptional strength. Furthermore, high-precision gear pumps and specially designed spinnerets guarantee a uniform filament diameter, a non-negotiable factor for the knot strength and durability of the final fishing net. As a leader like APEX integrates, intelligent control systems allow you to monitor and adjust these parameters in real-time, ensuring repeatable, high-quality production batch after batch. This technological synergy is what transforms standard PP or PE resin into the robust, reliable monofilament that defines premium fishing nets.

2.1、Precision Screw and Barrel Design for Optimal Polymer Processing

At the heart of your high-tenacity PP/PE monofilament extruder lies the screw and barrel system. This is where raw polymer granules are transformed into a homogeneous, high-strength melt. The design is not generic; it is meticulously engineered for the specific rheological properties of polypropylene and polyethylene. A typical high-performance screw features a deep feed section to gently intake material, followed by a precisely calculated compression zone that gradually melts the polymer without creating excessive shear heat that can degrade its molecular chains.

You need a screw with a long metering section to ensure the melt is uniform in temperature and viscosity before it enters the die. Any inconsistency here will directly translate into variations in your monofilament's diameter and, critically, its tensile strength. The screw's length-to-diameter (L/D) ratio is crucial; a higher ratio, often 30:1 or more, provides sufficient residence time for complete melting and mixing, which is essential for achieving the high tenacity you require.

The barrel works in tandem with the screw. It is typically constructed from bi-metallic alloys to withstand the abrasive nature of certain polymer additives and the constant pressure. Precision heating zones along the barrel allow you to establish a precise thermal profile, from the feed throat to the die adapter. This controlled heating, combined with the shear from the screw, ensures the polymer reaches its optimal processing window, maximizing orientation and strength potential in the downstream drawing process.

Furthermore, the clearance between the screw flight and the barrel wall is a critical tolerance. Too much clearance leads to polymer slippage and poor output consistency, while too little can cause excessive wear and overheating. Your extruder's design must strike the perfect balance to deliver a stable, high-pressure melt stream, which is the absolute foundation for producing monofilament with exceptional and reliable mechanical properties for demanding fishing net applications.

2.2、Advanced Spinline and Quenching System for Consistent Diameter

When you invest in a high-tenacity PP/PE monofilament extruder, the spinline and quenching system is where the magic of diameter control truly begins. This isn't a simple cooling step; it's a precisely engineered thermal management process that locks in the molecular orientation and physical properties of your filament from the very first moment it exits the die.

You need a quenching bath designed for rapid, uniform, and stable heat extraction. The temperature gradient, the flow dynamics of the cooling medium (usually water), and the bath length are all calibrated to ensure the molten polymer solidifies at a controlled rate. Any inconsistency here directly translates to variations in diameter, which weakens the overall tenacity and creates weak points in your final fishing net.

Advanced systems feature multi-zone temperature control and turbulence-free laminar flow. This environment ensures that every micron of the filament's surface cools at the same speed as its core, preventing the formation of a hard skin over a soft core—a defect that would lead to brittleness and poor drawability in later stages.

Furthermore, the spinline guidance and tension control between the die and the first godet roll are integral to this system. Precise alignment and minimal vibration are critical. Any wobble or oscillation in the spinline as it enters the quench bath will cause diameter fluctuation, which your downstream processes cannot correct. A stable spinline path is non-negotiable for the consistent diameter you demand.

Ultimately, this sophisticated quenching stage sets the foundation for all subsequent drawing and heat-setting processes. By delivering a filament with a perfectly consistent "as-spun" diameter and a uniform crystalline structure, it gives you the raw material needed to achieve the exceptionally high and reliable tenacity that defines premium fishing nets.

2.3、Multi-Stage Godet Units for Precise Drawing and Orientation

When you aim to produce high-tenacity monofilament, the extrusion process is only the beginning. The real transformation of molecular structure and the development of ultimate tensile strength occur during the drawing and orientation phase. This is where multi-stage godet units become the critical, non-negotiable component of your extruder line.

Think of these godet units as a series of precisely controlled rollers. Their primary function is to pull the still-molten or semi-molten filament from the die head at varying, independently adjustable speeds. The speed difference between consecutive godet sets creates the draw ratio. As you stretch the filament, you are aligning the long polymer chains (PP or PE) along the filament's axis. This orientation is what converts a weak, undrawn fiber into a strong, tenacious monofilament with low elongation and high resistance to creep.

A single-stage draw is insufficient for achieving the optimal balance of properties. A multi-stage system, typically involving 2 to 4 godet units, allows you to fine-tune the drawing process. You can implement a primary draw for gross orientation and a secondary, often heated, draw for final stabilization and property enhancement. This staged approach gives you unparalleled control over the filament's tenacity, modulus, and shrinkage characteristics.

Each godet unit in your system is engineered for precision. They feature individual DC or AC drive systems for exact speed synchronization, temperature-controlled surfaces (heated or cooled) to manage the polymer's thermal history during drawing, and sophisticated tension sensors. This level of control ensures that every meter of monofilament produced has consistent diameter and mechanical properties, which is fundamental for weaving uniform, reliable fishing nets.

Ultimately, investing in an extruder equipped with advanced multi-stage godet units means you are investing in the core quality of your fishing nets. It empowers you to dial in the exact tenacity and performance profile required by your customers, whether for heavy-duty trawling or precision aquaculture nets, ensuring your products stand up to the toughest marine challenges.

2.4、Integrated Heat Setting for Permanent Tenacity and Low Shrinkage

Integrated heat setting is the critical final step that locks in the molecular orientation achieved during drawing, giving your PP/PE monofilament its permanent high tenacity and exceptionally low shrinkage. Without this process, the filament would have a strong tendency to revert to its original, less-ordered state when exposed to heat, such as during net fabrication or in warm seawater, leading to dimensional instability and a loss of strength.

In your extruder line, this is typically accomplished using a multi-zone heated godet system or an oven. The drawn filament is passed through a precisely controlled thermal environment at a temperature above its glass transition point but below its melting point. This allows the polymer chains to relax slightly and re-crystallize into a new, stable configuration that "remembers" its highly oriented, extended state.

The precise control over temperature, tension, and residence time during this stage is paramount. Too little heat or time, and the setting is incomplete, leaving residual shrinkage. Too much, and you risk degrading the polymer or reducing tenacity. A well-engineered system provides you with the repeatable parameters needed to produce batch after batch of monofilament with consistent, guaranteed performance metrics.

The result for your fishing nets is a filament that will not shrink or weaken significantly under normal use and environmental conditions. This ensures the net maintains its designed mesh size and knot integrity, providing predictable catch efficiency and long-term durability that your end-users can rely on season after season.

3、Key Benefits of Upgrading to a Specialized Extrusion Line

When you upgrade to a specialized extrusion line, like those engineered by APEX, you unlock a new level of production efficiency and product quality. The core benefit lies in achieving consistently high tenacity in your PP/PE monofilament. This directly translates to fishing nets with superior tensile strength, exceptional abrasion resistance, and longer service life, giving your end-users the reliability they demand. For your business, this means reduced material waste, lower defect rates, and the ability to command a premium in the market. Furthermore, a dedicated line offers precise control over filament diameter and uniformity, ensuring every meter of netting performs identically. By investing in such advanced technology, you are not just buying a machine; you are securing a competitive edge built on durability and trust.

3.1、Significantly Higher Production Output and Yield

When you invest in a modern high-tenacity PP/PE monofilament extruder, the most immediate and tangible benefit you will experience is a dramatic increase in your production output. These specialized lines are engineered for speed and stability, operating at higher linear speeds without compromising the critical physical properties of the filament. This means you can produce more kilograms of high-quality monofilament per hour, directly translating to higher sales volumes and better utilization of your production floor.

Beyond raw speed, the advanced control systems and precision engineering of these extruders drastically improve your material yield. You will see a significant reduction in off-spec production, waste from diameter variations, and downtime due to line instability. Every kilogram of resin is utilized more efficiently, leading to lower production costs per unit and a healthier bottom line for your operation.

This enhanced output and yield are not achieved by pushing the machine to its limits chaotically. Instead, it's the result of synchronized components—from the high-precision screw design and optimized heating zones to the advanced quenching and multi-stage godet systems—working in harmony to maintain process stability at elevated speeds. You get consistent, high-tenacity filament, batch after batch, at a pace that meets growing market demands.

3.2、Consistent Filament Quality with Minimal Variation

When you invest in a high-tenacity PP/PE monofilament extruder, you are fundamentally purchasing control over your filament's consistency. The core design of these specialized lines integrates precision melt pumps, advanced temperature control zones, and highly stable winding systems. This engineered precision ensures that the diameter, tenacity, and elongation of every meter of filament you produce fall within an exceptionally tight tolerance range.

For your fishing net production, this minimal variation translates directly into predictable and superior performance. Nets woven from filaments with inconsistent diameters have weak points that are prone to premature failure under load. With a dedicated extruder, you eliminate these weak links, producing nets with uniform mesh strength and knot integrity that your customers can rely on in demanding conditions.

Furthermore, consistent quality streamlines your downstream processes. Your twisting, braiding, and net-making equipment runs more smoothly with a uniform feedstock, reducing downtime, minimizing waste from breaks or rejects, and significantly improving your overall production efficiency and yield.

Ultimately, the ability to guarantee consistent filament quality is a powerful competitive advantage. It allows you to meet stringent international standards, build a reputation for reliability, and command a premium in the market for high-performance fishing gear where failure is not an option.

3.3、Reduced Material Waste and Energy Consumption

When you operate a specialized high-tenacity PP/PE monofilament extruder, you directly tackle material waste at its source. The precision of the extrusion process, from screw design to temperature control zones, ensures optimal polymer melting and homogenization. This means you achieve consistent filament diameter and properties from the very first meter, drastically reducing the amount of off-specification material that would otherwise be scrapped or recycled at a loss. Every kilogram of resin you feed in is efficiently converted into sellable, high-quality monofilament.

Furthermore, the advanced control systems integral to these extruders allow you to fine-tune parameters in real-time. You can maintain the exact tension, cooling rate, and draw ratio needed for high tenacity without trial-and-error runs. This operational stability prevents the production fluctuations that lead to waste, ensuring your line runs efficiently from startup to shutdown, maximizing your raw material yield.

Energy consumption is another major cost center where a modern extruder delivers significant savings. These machines are engineered with high-efficiency drives, optimized heating and cooling circuits, and superior thermal insulation. The result is that a greater proportion of the electrical energy input is used for the actual extrusion and drawing process rather than being lost as waste heat. You get more meters of monofilament per kilowatt-hour.

By integrating a specialized extruder into your fishing net production, you're not just buying a machine; you're investing in a leaner, more sustainable manufacturing process. The combined reduction in material waste and lower energy bills directly improves your bottom line, making your nets more cost-competitive while also minimizing your environmental footprint—a crucial advantage in today's market.

3.4、Flexibility to Process Various PP/PE Grades and Additives

Your production demands are not static, and neither should your equipment be. A specialized high-tenacity monofilament extruder provides you with the crucial flexibility to process a wide spectrum of PP and PE grades. You are not locked into a single supplier's resin; you can select materials based on cost, availability, or specific performance targets like UV resistance, abrasion resistance, or buoyancy.

This adaptability extends to masterbatches and functional additives. Whether you need to incorporate colorants, anti-slip agents, or stabilizers to enhance weatherability, a versatile extruder with precise gravimetric dosing systems allows you to introduce these additives consistently and homogeneously into the melt stream. This ensures the final filament's properties are uniform from start to finish of a production run.

Furthermore, the ability to fine-tune processing parameters—such as temperature profiles across multiple zones, screw speed, and draw ratios—means you can optimize the extrusion line for different material viscosities and molecular weights. You can confidently switch from a standard homopolymer PP to a high-modulus copolymer or a specially formulated PE without sacrificing output quality or line stability.

Ultimately, this flexibility is a direct competitive advantage. It empowers you to respond swiftly to market trends, develop custom net solutions for different fishing applications (e.g., trawling vs. gillnets), and optimize your raw material costs without compromising the high-tenacity performance that defines your product.

4、How to Choose the Right Extruder for Your Fishing Net Business

Choosing the right high tenacity PP/PE monofilament extruder is a critical investment for your fishing net business. You must consider several key factors to ensure the machine meets your specific production demands. First, evaluate the extruder's output capacity and filament diameter range to match your target net specifications. The technology behind the screw design and temperature control is paramount for achieving the consistent, high-tenacity properties your nets require for durability.

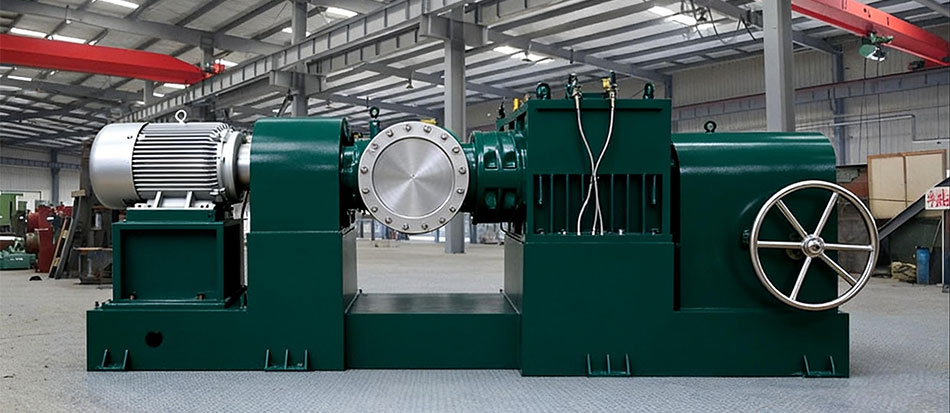

As a leader in this field, APEX (Qingdao Apex Machinery Technology Co., Ltd.) offers specialized solutions. Our extruders are engineered with precision, integrating advanced control systems that ensure stable extrusion of ultra-strong monofilaments. With over a decade of R&D and a proven track record serving global clients, we understand the harsh conditions fishing nets endure. Our equipment is designed not just for high performance but also for energy efficiency and operational simplicity, helping you reduce costs and enhance productivity.

Ultimately, the right partner provides more than a machine; they offer comprehensive support from installation to maintenance. By selecting a technologically advanced and reliable supplier like APEX, you secure a foundation for producing superior, competitive fishing nets that stand up to the challenge of the sea, strengthening your business for the long term.

4.1、Assessing Your Target Filament Denier and Tenacity Requirements

Your journey to selecting the perfect extruder begins with a crystal-clear definition of your product's core specifications. The target filament denier (or dtex) and tenacity are not just numbers on a datasheet; they are the fundamental engineering parameters that dictate the extruder's required capabilities. You must ask yourself: What is the breaking strength and elongation profile my fishing net customers demand for their specific applications?

For instance, deep-sea trawling nets require filaments with extremely high tenacity, often exceeding 7-8 grams per denier (g/d), to handle massive loads and abrasive sea floors. In contrast, lighter gillnets or aquaculture cages might prioritize a balance of moderate strength and flexibility. The extruder you choose must have a precise and robust screw design, temperature control system, and drawing unit capable of achieving and consistently maintaining this specific molecular orientation and crystallinity.

Furthermore, the denier range you plan to produce directly impacts the extruder size and downstream equipment. A machine optimized for producing fine deniers (e.g., 100-500 denier) for delicate nets will differ from one built for heavy-duty monofilaments (e.g., 2000+ denier). You need to verify the extruder's nominal output rate and its compatibility with your target denier to ensure efficient production without bottlenecks or quality compromises.

Therefore, before evaluating any equipment, collaborate closely with your R&D and sales teams to finalize these technical targets. This assessment becomes your primary checklist against which every extruder's specifications will be measured, ensuring the machine you invest in is engineered to deliver the exact high-tenacity PP/PE monofilament your business is built on.

4.2、Evaluating Production Capacity and Line Speed Needs

To evaluate your production capacity needs, you must first analyze your target market and order volume. Ask yourself: What is your current and projected annual output in tons? Are you focusing on large-scale industrial fishing nets or smaller, specialized gear? The extruder's throughput, measured in kilograms per hour (kg/h), must align with these targets. An undersized machine creates bottlenecks, while an oversized one ties up capital and increases operational costs unnecessarily.

Line speed is intrinsically linked to capacity but focuses on the process efficiency. It's measured in meters per minute (m/min) and directly impacts the filament's properties. You need a machine that offers a wide, controllable speed range. Higher speeds increase output but require precise temperature control and quenching to maintain the high tenacity and consistent diameter you demand. A machine that can only run at a fixed, low speed will limit your flexibility and profitability.

Consider the entire production line, not just the extruder. The take-up and winding systems must be capable of handling the line speed your extruder generates. A mismatch here will cause breaks, downtime, and quality issues. Furthermore, evaluate if you need a single-line setup or multiple lines. For higher capacity, sometimes running two optimized lines is more efficient and reliable than pushing one machine to its absolute limit.

Finally, factor in future growth. Choose an extruder with a 20-30% capacity buffer above your current needs. This allows you to handle larger orders and scale up without immediately requiring a new capital investment. A modular machine design that allows for future upgrades in screw configuration, heating zones, or cooling baths can be a wise long-term investment for your fishing net business.

4.3、Importance of Automation and Ease of Operation

When selecting a high tenacity PP/PE monofilament extruder, the level of automation is not a luxury; it's a critical determinant of your production efficiency and product consistency. A highly automated system minimizes manual intervention, which directly translates to reduced human error. For you, this means every batch of monofilament maintains the precise diameter, tenacity, and elongation properties required for top-grade fishing nets. Automated controls for temperature, screw speed, haul-off, and winding ensure that the process parameters remain stable 24/7, delivering the uniformity that your customers rely on.

Ease of operation is equally vital. A user-friendly control interface, preferably with a touch-screen HMI (Human-Machine Interface), allows your operators to set up, monitor, and adjust the extrusion line with minimal training. Complex recipes for different PP/PE blends or filament diameters can be stored and recalled instantly, enabling quick product changeovers. This flexibility is key to responding to diverse market demands without sacrificing machine uptime or material waste during transitions.

Furthermore, consider the automation of auxiliary systems. An extruder integrated with automated dosing, drying, and coloring systems streamlines the entire material handling process. Automated defect detection and tension control during winding prevent substandard monofilament from reaching the final spool. For your business, this integrated automation safeguards your raw material investment and guarantees that every meter of filament produced meets the high-tenacity standard, enhancing your brand's reputation for reliability.

Ultimately, investing in an extruder with advanced automation and intuitive operation is an investment in your operational sovereignty. It reduces dependency on highly specialized labor, lowers long-term operational costs, and empowers you to scale production predictably. In the competitive fishing net industry, the machine that offers superior control with simpler operation gives you the decisive edge in producing durable, consistent, and high-performance monofilament efficiently.

4.4、Considering Supplier Expertise and After-Sales Support

When you invest in a high-tenacity PP/PE monofilament extruder, you are not just buying a machine; you are entering a long-term partnership with the supplier. The technical complexity of this equipment means that the supplier's expertise is a critical component of your success. You need a partner who understands the nuances of polymer rheology, die design for high-tenacity output, and precise cooling and drawing processes. A supplier with deep application knowledge in fishing nets can provide invaluable guidance on resin selection, process optimization, and troubleshooting, ensuring your line produces filament that meets the exacting standards for knot strength, abrasion resistance, and UV stability.

Beyond the initial sale, robust after-sales support is your safety net. You must evaluate the supplier's service network. Do they have readily available, trained technicians who can respond quickly to your location? Downtime in extrusion is extremely costly. A reliable supplier will offer comprehensive support packages, including installation supervision, operator training, preventive maintenance plans, and a clear spare parts supply chain. You should prioritize suppliers who provide detailed technical documentation and 24/7 remote support to help you resolve process issues swiftly, minimizing production interruptions.

Finally, consider the supplier's commitment to innovation and long-term relationship. The fishing net industry evolves, and so should your technology. A forward-thinking supplier will offer upgrades and share insights on new materials or process improvements. Choosing a partner with a proven track record and a customer-centric approach ensures that your extruder remains a productive and competitive asset for years to come, directly impacting the quality and reliability of the fishing nets you produce.

Investing in a high tenacity PP/PE monofilament extruder for fishing nets is a strategic decision that elevates your entire production capability. It's about committing to quality, efficiency, and the long-term satisfaction of your end-users who rely on the toughest nets available.

By now, you understand the critical features, benefits, and selection criteria that define top-tier extrusion systems. The right machine doesn't just meet specifications; it becomes a reliable partner in your growth, helping you capture more market share with superior products.

When seeking a partner for this advanced technology, consider APEX - Qingdao Aipake Machinery Technology Co., Ltd. Established in 2014, APEX is a high-tech enterprise specializing in the R&D, manufacturing, and sales of high-end rubber and plastic machinery. With a provincial engineering center and an intelligent production base, we are dedicated to providing advanced, energy-saving, and intelligent industrial solutions. Our expertise in monofilament extrusion for applications like fishing nets is backed by a global presence, serving over a thousand leading clients across more than 30 countries. Let APEX be your trusted partner in building a stronger, more efficient future for your fishing net production.

Next Article:中国青岛橡胶开炼机工厂实地考察:探秘高端橡塑机械的制造核心