Factory Site Visit to Rubber Open Mixing Mill Factory in Qingdao, China: An Inside Look at APEX's Advanced Manufacturing

Factory site visit to rubber open mixing mill factory in Qingdao, China offers you a unique opportunity to witness cutting-edge rubber processing technology firsthand. If you're sourcing equipment or seeking a reliable manufacturing partner, seeing the operations on the ground is invaluable. This virtual tour will guide you through what makes a visit to a leading facility like APEX so insightful for your business.

You'll get a clear picture of the precision engineering, stringent quality controls, and innovative solutions that define modern rubber mixing. Understanding the factory environment helps you assess capability, reliability, and the potential for a successful partnership. Let's step inside and explore the key aspects you should focus on during such a visit.

From the moment you arrive, the scale of specialization and commitment to industrial excellence becomes apparent. This isn't just about observing machines; it's about evaluating a complete ecosystem designed for efficiency and superior output. Your journey to finding the right open mixing mill starts here, with a detailed look behind the scenes.

1、First Impressions: The Factory Layout and Scale

1.1、Organized Production Zones and Workflow

1.2、Scale of Operations and Manufacturing Capacity

1.3、Cleanliness, Safety, and 5S Management Standards

2、Core Technology in Action: The Open Mixing Mill Line

2.1、Machine Precision and Build Quality Inspection

2.2、Observing the Mixing Process and Material Handling

2.3、Key Features: Cooling, Control Systems, and Safety Mechanisms

3、Quality Assurance and Testing Protocols

3.1、In-Process Quality Checks and Data Recording

3.2、Final Product Testing and Performance Validation

3.3、Certifications and Compliance Standards Met

4、Behind the Scenes: R&D and Customization Capability

4.1、Tour of the Engineering and Design Center

4.2、Discussing Custom Solutions for Your Specific Needs

4.3、Prototyping and Client Collaboration Process

5、Evaluating the Partnership: Support and Global Reach

5.1、After-Sales Service and Technical Support Structure

5.2、Spare Parts Logistics and Training Programs

5.3、Understanding Global Export and Client Portfolio

1、First Impressions: The Factory Layout and Scale

As you step into APEX's manufacturing complex in Qingdao, the first impression is one of organized scale and purpose-driven design. The factory layout is not a random collection of workshops but a meticulously planned ecosystem that mirrors the company's commitment to advanced, intelligent manufacturing. You immediately notice the clear zoning: dedicated areas for raw material storage, precision machining, assembly lines for different product categories like the rubber open mixing mills, and final testing stations. This logical flow minimizes cross-contamination and optimizes production efficiency, a critical factor for a high-tech enterprise serving global clients in demanding sectors such as automotive and medical industries. The sheer scale of the operation underscores APEX's capacity as a significant player, capable of handling large-volume orders while maintaining the flexibility for customized solutions. The clean, well-lit environment and visible safety protocols reinforce the professionalism and stringent quality standards that define their brand, setting the stage for a deeper exploration of their technological prowess.

1.1、Organized Production Zones and Workflow

As you enter the organized production zones, you immediately notice the logical, unidirectional workflow designed to minimize material handling and cross-contamination. Raw material storage and pre-processing are strategically positioned at the start of the line, feeding directly into the primary mixing area where the open mills operate.

Your attention is drawn to the clear demarcation between different functional areas: component machining, frame welding and stress-relieving, assembly, electrical integration, and final testing. This segregation ensures specialized focus at each stage and maintains a smooth, efficient production cadence from raw steel to a finished, tested machine.

You can observe how work-in-progress moves systematically from one zone to the next, with designated pathways and staging areas. This organization is not just about cleanliness; it's a critical component of quality control, traceability, and achieving consistent, on-time delivery for every open mixing mill produced.

1.2、Scale of Operations and Manufacturing Capacity

As you move from the initial layout overview, the sheer scale of operations immediately commands your attention. You are not looking at a single production line but a coordinated network of them, designed for high-volume, continuous manufacturing. The floor space dedicated to assembly, testing, and staging of finished open mixing mills reveals a capacity geared towards meeting significant global demand, not just small-batch orders.

Your assessment of manufacturing capacity goes beyond counting machines. You observe the organized workflow where key components—like the mixing chamber, rotors, and hydraulic systems—are machined, assembled, and tested in dedicated zones. This segmentation indicates a streamlined process that minimizes bottlenecks, ensuring that production timelines are predictable and reliable for your project planning.

You will notice the inventory of raw materials and major parts, such as high-grade steel plates and castings. A well-managed inventory at this scale is a critical indicator of a factory's ability to handle multiple concurrent orders without delays. It directly translates to shorter lead times for you when placing an order.

Furthermore, the presence of multiple units in various stages of completion—from welding and machining to final paint and packaging—provides tangible proof of their throughput. This visible pipeline allows you to gauge their real-time production rhythm and confirms their claims of being a high-capacity manufacturer capable of scaling to meet your specific requirements.

1.3、Cleanliness, Safety, and 5S Management Standards

Upon entering the production area, you will immediately notice the meticulous organization and spotless environment. This is not a coincidence but a direct result of rigorous 5S management standards—Sort, Set in order, Shine, Standardize, and Sustain. Every tool has a designated place, floors are free of debris and oil spills, and workstations are logically arranged to minimize unnecessary movement and prevent cross-contamination of rubber compounds.

Your attention will then be drawn to the comprehensive safety protocols visibly integrated into daily operations. Clearly marked safety zones, prominent warning signs, mandatory personal protective equipment (PPE) stations, and well-maintained machine guards are all in place. You can observe that operators are trained to follow strict procedures, ensuring not only their own safety but also the consistent quality of the mixing process by preventing accidents that could lead to material waste or equipment damage.

This high standard of cleanliness and order directly impacts the quality of the machinery produced. A clean factory floor indicates disciplined production control and reduces the risk of foreign particles contaminating precision components during assembly. For you, this translates to receiving equipment built in an environment that prioritizes precision and reliability from the ground up.

Finally, the sustained implementation of these systems demonstrates the factory's commitment to continuous improvement and operational excellence. It shows a management philosophy that values efficiency, employee welfare, and product integrity. When you see 5S and safety deeply embedded in the culture, it provides strong confidence in the factory's overall capability and stability as a long-term manufacturing partner for your critical rubber processing equipment.

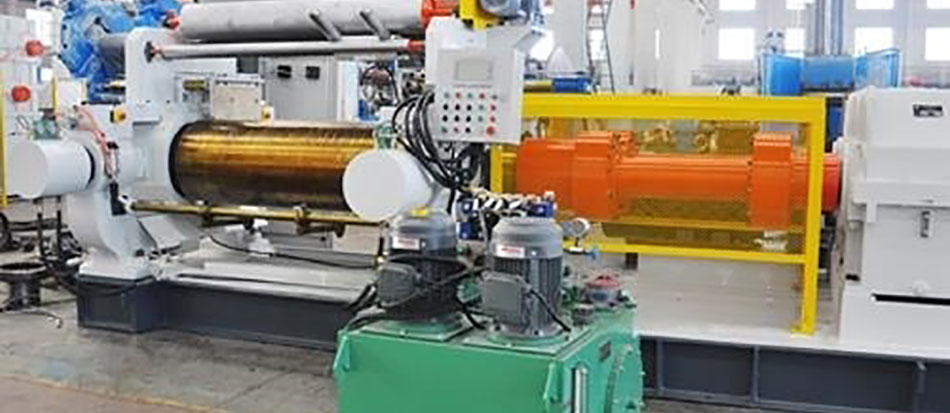

2、Core Technology in Action: The Open Mixing Mill Line

As you step onto the production floor of APEX's factory in Qingdao, the heart of their operation becomes immediately clear: the advanced open mixing mill line. Here, you witness the core technology that transforms raw rubber compounds into uniform, high-quality masterbatches. You see the massive, precisely engineered rolls in motion, their temperature and gap meticulously controlled by APEX's proprietary automation systems. This isn't just heavy machinery; it's a demonstration of the intelligent, energy-efficient solutions the company is known for. Observing the seamless integration of mechanical power and digital control gives you tangible proof of their commitment to providing advanced industrial equipment for sectors like automotive and construction.

Your guide explains how each mill is designed for optimal dispersion and shear, critical for consistent product performance. You can assess the robust construction, the attention to safety features, and the streamlined workflow designed for high output. This direct observation allows you to evaluate the build quality and operational logic firsthand, confirming why APEX's open mills are trusted by global clients. Seeing this core technology in action bridges the gap between technical specifications on paper and real-world, reliable manufacturing capability, helping you make a more informed sourcing decision.

2.1、Machine Precision and Build Quality Inspection

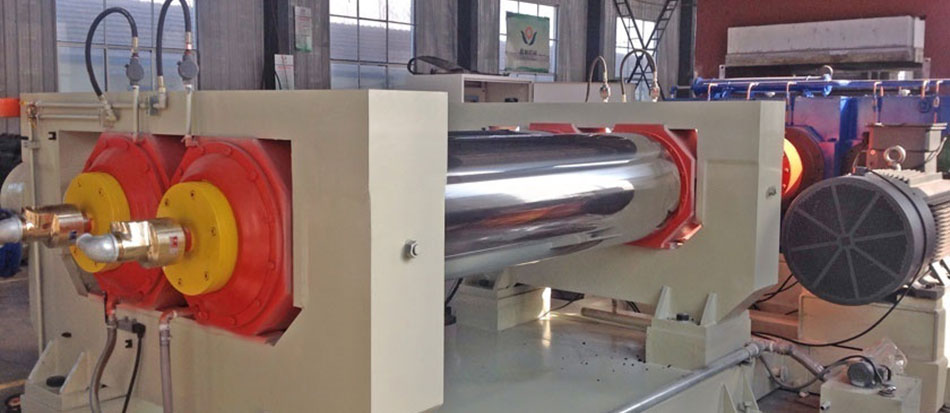

When you inspect the machine precision and build quality, start with the frame and core components. You will see massive, stress-relieved steel castings or fabrications that form the mill's base. Look for seamless welding, uniform thickness, and the absence of surface imperfections. This foundational integrity is non-negotiable for withstanding decades of high-torque operation and preventing frame deformation, which directly impacts mixing consistency and bearing life.

Next, focus on the milling chamber and rotors. The inner surfaces of the side housings and the rotor blades should exhibit a mirror-like finish, achieved through precision grinding and polishing. This ultra-smooth finish is critical; it minimizes material adhesion, ensures efficient heat transfer, and facilitates easy cleaning between batches. You can visually and tactilely assess this finish to gauge the level of post-machining care.

Examine the alignment and tolerances of the rotating assembly. Ask to see documentation for run-out tolerances on the rotor shafts and the gear engagement. Precision here translates to minimal vibration, reduced energy consumption, and uniform shear forces on the rubber compound. Observe the mill in idle operation; a well-built machine runs with a deep, steady hum, not with clatters or irregular noises.

Finally, scrutinize the fit and finish of ancillary systems. Check hydraulic lines for neat routing and secure clamping. Inspect electrical cabinets for organized wiring and high-quality components like Siemens or Schneider contactors. The quality of these supporting systems is a reliable indicator of the overall build philosophy—whether it's focused on long-term reliability or mere cost-cutting.

2.2、Observing the Mixing Process and Material Handling

As you observe the mixing process, you'll first notice the precise material handling system. Raw rubber, carbon black, oils, and various chemical additives are weighed and fed into the mill with exacting accuracy. This initial stage is critical; any deviation in formulation can compromise the final product's properties. You'll see automated or semi-automated systems minimizing human error, ensuring batch-to-bust consistency from the very start.

Your attention will then be drawn to the two counter-rotating rolls of the open mixing mill itself. The operator, or 'mill man', skillfully manipulates the rubber compound as it passes through the nip—the gap between the rolls. You'll witness how the shear force and heat generated here disperse fillers, break down polymer chains for plasticity, and homogenize the entire mixture. Observing the operator's technique in cutting and folding the bank of material is key to understanding the art behind this mechanical science.

Throughout the cycle, you can assess the factory's process control. Temperature readings for both rolls and the compound itself are constantly monitored. The duration of mixing for each stage—mastication, incorporation, and dispersion—is tightly controlled. This disciplined approach prevents under-mixing (leading to inhomogeneity) or over-mixing (which can cause scorch or degradation), directly impacting the quality of the downstream products like sheets or slabs.

Finally, you'll observe the discharge and handling of the finished batch. The homogeneous rubber sheet is cleanly stripped from the roll and either cooled on a conveyor or directly fed into the next processing stage. The efficiency and care in this phase prevent contamination and preserve the compound's properties. This end-to-end observation allows you to evaluate the factory's mastery over the entire material flow, a definitive indicator of their capability to deliver reliable, high-performance open mixing mills.

2.3、Key Features: Cooling, Control Systems, and Safety Mechanisms

When you observe the open mixing mill in operation, the advanced cooling system is immediately apparent. It is not a simple water jacket; it's a precisely engineered, multi-zone temperature control system. The mill's rolls are internally drilled and channeled to allow for the circulation of a cooling medium, ensuring that the heat generated during the intensive shearing and mixing of rubber compounds is efficiently dissipated. This prevents thermal degradation of sensitive polymers and additives, guaranteeing batch-to-batch consistency in compound viscosity and final product properties that you require.

Your attention will then be drawn to the integrated control systems. Modern mills feature PLC (Programmable Logic Controller) or even PC-based control panels with intuitive HMI (Human-Machine Interface) screens. From here, you can set and monitor critical parameters like roll speed, friction ratio, nip gap, and mixing temperature in real-time. This level of automation allows for precise recipe management, repeatable processing cycles, and comprehensive data logging for quality traceability, directly addressing your need for process control and documentation.

Safety mechanisms are paramount and are designed with operator protection as the core principle. You will notice robust emergency stop buttons at multiple accessible locations. The machines are equipped with mechanical safety brakes that engage instantly when the E-stop is activated. Furthermore, modern designs often include interlocked safety guards that completely cut power to the drive motors when opened, preventing any accidental contact with moving parts. These features ensure a safe working environment, which is a critical factor for any responsible manufacturing partnership.

Beyond these, key features also encompass the robust construction of the gearbox and bearings, designed for continuous heavy-duty operation with minimal maintenance. The precision-machined rolls, often made from chilled cast iron with a hardened surface, ensure uniform mixing and long service life. Together, these features—cooling, control, and safety—form a cohesive system that transforms raw rubber into a homogeneous, high-quality compound efficiently, reliably, and safely, which is the exact outcome you seek from your equipment investment.

3、Quality Assurance and Testing Protocols

During your factory site visit to APEX's rubber open mixing mill facility in Qingdao, the emphasis on Quality Assurance and Testing Protocols is immediately tangible. You will witness a systematic approach where every critical component, from the robust mixing chamber to the precision gearbox, undergoes rigorous inspection. This isn't just about final product checks; it's a process embedded at every manufacturing stage, reflecting the company's commitment as a high-tech enterprise with a provincial engineering center. You can see dedicated testing stations where mills run under simulated full-load conditions, with technicians meticulously recording data on temperature control, mixing uniformity, and energy consumption. This hands-on validation ensures that the advanced, energy-saving solutions APEX promises are not just theoretical but proven on the shop floor before shipment. For you as a potential partner, this transparent protocol is a direct assurance of equipment reliability and longevity, crucial for serving demanding global industries.

3.1、In-Process Quality Checks and Data Recording

During your factory visit, you will observe a rigorous system of in-process quality checks integrated directly into the production workflow. At key stages of the open mixing mill assembly, technicians perform dimensional verifications, torque tests on critical fasteners, and visual inspections of welds and surface finishes. This is not a final inspection; it's a proactive control mechanism designed to catch and correct deviations immediately, preventing non-conformities from moving to the next station.

You will notice that every check is tied to a digital data recording system. Operators use tablets or fixed terminals to log measurements, test results, and any observations directly into the factory's Manufacturing Execution System (MES). This real-time data entry eliminates paper-based errors and creates a traceable, time-stamped record for every single machine component and assembly step, providing you with unparalleled transparency.

The data collected isn't just stored; it's actively analyzed. On large monitors in the production area, you can see control charts displaying key parameters like rotor clearance or gearbox alignment data. Supervisors and quality engineers monitor these trends in real-time. If a measurement begins to drift toward a control limit, the system flags it, prompting immediate corrective action before any specification is breached, ensuring consistent product quality.

This meticulous approach means that by the time a mixing mill reaches the final testing phase, its quality is already assured. The in-process records provide you with a complete digital birth certificate for the equipment you are sourcing, offering concrete evidence of controlled, precise manufacturing and giving you confidence in the machine's reliability and performance before it even leaves the factory floor.

3.2、Final Product Testing and Performance Validation

During your factory visit, you will witness the final and most critical stage of quality assurance: the comprehensive testing and performance validation of the finished open mixing mill. This is where APEX's commitment to delivering reliable, high-performance equipment is tangibly proven. You will see that every machine undergoes a rigorous series of operational tests before it is approved for shipment.

You can expect to observe the mill running under simulated production conditions. Technicians will load rubber compounds and run the machine through various speed and pressure settings to ensure smooth operation of the drive system, bearings, and mixing chamber. They meticulously check for any abnormal vibrations, noises, or leaks, which are immediate indicators of assembly precision and component quality.

Key performance parameters are measured and recorded against strict specifications. This includes verifying the accuracy of temperature control systems in the mixing chamber and rotors, confirming the consistency of the hydraulic or pneumatic system pressure, and testing the responsiveness of the safety interlocks and emergency stop functions. You will see data loggers in use, providing objective evidence that the machine performs as designed.

Furthermore, the final validation often includes a test mix with a standard compound. This allows the engineers to assess the machine's actual mixing efficiency, dispersion quality, and temperature profile during a working cycle. The resulting rubber batch may be tested for uniformity, providing a direct link between machine performance and end-product quality for your own production.

This hands-on validation process gives you, as a potential buyer, the utmost confidence. It transforms specifications on paper into a demonstrable reality. Witnessing this final checkpoint assures you that the equipment you are investing in is not just assembled, but fully commissioned and ready to integrate into your production line to deliver consistent, high-quality output from day one.

3.3、Certifications and Compliance Standards Met

When you evaluate a factory, the certifications on the wall are not just plaques; they are your primary assurance of systemic quality and international compliance. At APEX's facility in Qingdao, you will find a comprehensive framework of certifications that validates every stage of manufacturing, from raw material intake to final dispatch. These are not merely achieved but are actively maintained through rigorous internal and external audits, ensuring that the open mixing mills you source are built to globally recognized benchmarks.

You will see that core international standards like ISO 9001 for quality management systems form the backbone of their operations. This certification means that the processes you witness—from precision machining to assembly and testing—are documented, controlled, and continuously improved. It provides you with the confidence that there is a repeatable system in place to deliver consistent product quality, batch after batch, which is critical for your own production stability.

Beyond quality management, compliance with CE marking for machinery safety is paramount for your market access, particularly in Europe. During your visit, you can discuss how the engineering design incorporates essential health and safety requirements, with supporting technical documentation and risk assessments. This proactive approach to safety-by-design protects your operators and facilitates smoother customs clearance and market entry for the equipment you purchase.

Furthermore, the factory's adherence to stringent environmental and occupational health standards reflects a mature, responsible manufacturing ethos. This holistic compliance reduces your supply chain risks and aligns with modern corporate responsibility expectations. Ultimately, these certifications are your tangible proof that the factory operates at an elite industrial level, giving you a solid, verifiable foundation for trust and a competitive edge in your own rubber product manufacturing.

4、Behind the Scenes: R&D and Customization Capability

During your factory site visit to APEX in Qingdao, you will quickly move beyond the impressive production floor to the true engine of innovation: the R&D and customization hub. Here, you witness firsthand how APEX transforms client requirements into tangible, high-performance machinery. As a high-tech enterprise with a provincial-level engineering center, APEX's R&D team is dedicated to developing advanced, energy-efficient, and intelligent solutions. You can see engineers simulating processes, testing new materials for rubber mixing, and refining control systems to enhance precision for diverse applications from automotive parts to medical tubing.

This behind-the-scenes access allows you to evaluate their customization capability directly. Whether you need a specific configuration for an open mixing mill to handle unique compound recipes or require integration with downstream equipment, you can discuss your project with the technical team in real-time. Seeing their collaborative approach and advanced prototyping facilities gives you confidence that APEX can tailor equipment to your exact operational needs, ensuring the machinery you source is not just standard but optimized for your success in a competitive global market.

4.1、Tour of the Engineering and Design Center

Your tour of the Engineering and Design Center begins in a dynamic, collaborative space where conceptual ideas transform into precise technical drawings. You will see teams of engineers utilizing advanced CAD/CAE software to model every component of an open mixing mill, from the massive frame to the intricate gear transmission system. This digital-first approach allows for rigorous simulation of stress, thermal flow, and operational dynamics long before any metal is cut, ensuring the fundamental design is robust and optimized for performance and longevity.

As you move through the center, you'll observe dedicated workstations for electrical and control system design. Here, engineers program and simulate the PLC and HMI interfaces that will become the intuitive control panel for your operators. You can discuss how these systems are tailored for different levels of automation, from basic manual controls to fully integrated, data-logging smart factories, giving you a clear understanding of the customization available for your specific production needs.

Perhaps most critically, you will witness the direct link between R&D and the factory floor. Prototype testing areas and material science labs are often adjacent. Here, new alloy formulations for mixing chambers or innovative bearing designs are tested under simulated extreme conditions. This proximity ensures that theoretical improvements are rapidly validated with practical, empirical data, a process that directly translates into more reliable and efficient machines for your rubber processing line.

Finally, the center houses the project management hub where your custom order comes to life. Large screens display Gantt charts and 3D models of ongoing projects. This transparency shows you how APEX manages the entire lifecycle of your equipment—from initial design consultation and material procurement to manufacturing scheduling and quality checkpoints—ensuring your specific requirements are meticulously tracked and executed from day one.

4.2、Discussing Custom Solutions for Your Specific Needs

During your visit, the engineering team will sit down with you to translate your specific rubber compound requirements into a precise technical specification for the open mixing mill. This is where your challenges—whether it's achieving a unique dispersion level, handling a new polymer blend, or meeting stringent energy consumption targets—are directly addressed. You will see how their deep application knowledge informs the design of critical components like the mixing chamber geometry, rotor profiles, and cooling systems to match your exact process.

You will be presented with a range of customization options that go beyond standard models. This includes selecting specific motor power and drive configurations for your desired torque and speed, choosing specialized materials for liners and rotors to combat abrasion or corrosion from your additives, and integrating advanced control systems for precise temperature and batch time management. The discussion is data-driven, focusing on how each modification impacts your final product quality and operational efficiency.

The factory's modular design approach becomes clear here. You can witness how they can scale the machine size, adjust the nip gap mechanism, or add ancillary systems like automated weighing and feeding units based on your production volume and automation level. This flexibility ensures the delivered mill is not an off-the-shelf product but a tailored solution integrated into your production line.

Finally, you will review case studies or even see assembly lines for previous custom projects. This tangible evidence allows you to assess their proven capability in solving problems similar to yours. The goal of this discussion is to move from a general inquiry to a collaboratively developed, technically sound proposal that gives you confidence the final equipment will perform as required in your specific operating environment.

4.3、Prototyping and Client Collaboration Process

During your visit, you will see that prototyping is not a separate stage but an integrated, collaborative workflow. The process begins with your technical team and APEX engineers holding a detailed kick-off meeting, often in a dedicated collaboration room. Here, you present your specific rubber compound requirements, production volume targets, and any unique challenges. The engineers translate these needs into initial machine specifications and a project timeline.

You will then observe the digital design phase, where 3D models and simulations are created. This allows for virtual testing of the mixing chamber geometry, rotor design, and cooling systems against your material parameters. Before any metal is cut, you have the opportunity to review these models, ensuring the conceptual design aligns perfectly with your process goals. This step prevents costly misunderstandings later.

The physical prototyping phase is where collaboration intensifies. For critical components like rotors or mixing chambers, you might witness the machining of a prototype. APEX may run controlled trials with your actual rubber compound samples (or close equivalents) in a pilot-scale or designated testing mill. You are encouraged to be present for these trials. Observing the mixing behavior, temperature profiles, and dispersion quality firsthand provides irreplaceable data for final adjustments.

Feedback from these trials is immediately incorporated. The iterative cycle of test-feedback-modification continues until the prototype meets all agreed-upon performance benchmarks. This process validates not only the machine's functionality but also the partnership's communication efficiency. You leave the prototyping phase with confidence, having co-developed a solution tailored to your exact production reality.

5、Evaluating the Partnership: Support and Global Reach

When you evaluate a partnership with a factory like APEX, the on-site visit reveals far more than just machinery; it showcases the comprehensive support system and global infrastructure that will back your investment. You can directly assess their technical support team's expertise, the availability of spare parts, and the efficiency of their after-sales service protocols. This is crucial for ensuring minimal downtime and long-term operational success for your open mixing mill.

Furthermore, APEX's established global reach, serving over 30 countries, is not just a sales statistic you hear about—it's a tangible advantage you witness. During the visit, you might see logistics coordination, documentation for international standards, and evidence of a deep understanding of diverse market requirements. This global perspective, combined with their provincial-level engineering R&D center, means the solutions you see are designed not just for local excellence but for reliable performance worldwide, giving you confidence in a truly scalable partnership.

5.1、After-Sales Service and Technical Support Structure

When you evaluate a factory, the after-sales service and technical support structure is not an add-on; it is a core component of the machine's lifecycle and your operational continuity. At a facility like APEX in Qingdao, you should look for a structured, proactive system rather than a reactive one. This begins with a clear, documented support protocol presented to you during the visit.

You need to understand the tiers of support available. Typically, this includes immediate remote assistance via phone or video call for troubleshooting, followed by on-site engineer dispatch if necessary. Ask about the average response time and the geographical coverage of their service network. A manufacturer with a global reach will have service hubs or certified partners in key regions to minimize your downtime.

Inquire about the training provided. Comprehensive support includes operational and maintenance training for your technicians at the factory or your site. This knowledge transfer empowers your team to perform routine maintenance and identify minor issues, preventing small problems from escalating into major production stoppages.

Examine the parts supply chain. A robust support structure guarantees the availability of critical spare parts. You should verify the inventory management system for genuine parts and the logistics framework that ensures timely delivery. The goal is to have a predictable and swift parts replacement process to keep your mixing mill running efficiently.

Finally, assess the long-term technical partnership. The best manufacturers offer periodic check-ins, software updates for control systems, and performance optimization advice as your production needs evolve. This ongoing dialogue turns a one-time purchase into a sustained collaborative relationship, ensuring your equipment remains at peak performance throughout its service life.

5.2、Spare Parts Logistics and Training Programs

When you evaluate a factory's long-term partnership value, spare parts logistics is a critical test of their commitment. At APEX, you'll see a systematic approach designed to minimize your equipment downtime. The factory maintains a comprehensive inventory of critical components, from rotors and bearings to seals and liners. More importantly, they operate a streamlined global logistics network, ensuring that urgent parts can be shipped via expedited channels. You should inquire about their average response time for spare parts requests and their tracking system, which provides transparency from warehouse dispatch to your facility's doorstep.

Beyond parts availability, the factory's training programs are essential for maximizing your return on investment. During your visit, you can review their structured curriculum, which typically includes on-site installation guidance, operational training for your technicians, and advanced maintenance workshops. These programs are not generic; they are tailored to the specific model of open mixing mill you purchase. You will gain confidence knowing that your team is equipped with the knowledge to operate the machinery efficiently and perform basic troubleshooting, thereby extending the equipment's lifecycle.

The synergy between logistics and training creates a robust support ecosystem. For instance, while a spare part is en route, APEX's technical support team can guide your trained personnel through preliminary diagnostic steps remotely. This integrated approach ensures that support is continuous and multi-faceted. You should assess the accessibility of their technical support—whether it's via phone, email, or a dedicated online portal—and the availability of service engineers for complex on-site interventions when necessary.

Finally, evaluating these programs helps you gauge the factory's dedication to a partnership, not just a transaction. A manufacturer that invests in comprehensive after-sales support demonstrates confidence in its product's reliability and a vested interest in your operational success. Your site visit allows you to verify these structures firsthand, discussing real-world scenarios with their support managers and perhaps even meeting the training instructors. This due diligence is crucial for ensuring a smooth, productive lifecycle for your rubber open mixing mill.

5.3、Understanding Global Export and Client Portfolio

When you evaluate a factory's global export capabilities, you are not just looking at shipping logistics; you are assessing its proven ability to meet diverse international standards and client expectations. A visit to APEX's factory in Qingdao allows you to see the tangible evidence of a global footprint. You can review documentation, see crates marked for different continents, and understand the logistical framework that ensures timely delivery to your region, whether in Southeast Asia, Europe, the Middle East, or the Americas.

Examining the client portfolio provides critical insight into the factory's reputation and specialization. During your site visit, inquire about long-term partnerships with established brands across various industries. A diverse yet focused portfolio—serving clients in tire manufacturing, automotive parts, industrial goods, and technical rubber products—indicates the factory's versatility and reliability. It demonstrates that their open mixing mills have been tested and trusted in real-world, high-demand applications.

Furthermore, understanding the adaptation of equipment for different markets is key. You should observe how the factory manages customization requests to comply with specific regional safety norms, voltage requirements, and technical specifications. This flexibility is a direct result of extensive export experience. Seeing machines configured for various international standards confirms that the factory is a strategic partner capable of seamlessly integrating its products into your local operation.

Finally, the presence of a dedicated international service and support team is a crucial component of global reach. You need to verify that post-sale support, technical training, and spare parts supply are structured for global clients. A factory with a mature export business will have established channels for remote diagnostics, multilingual documentation, and a network of service engineers, ensuring that your investment is protected and supported long after the machine leaves the Qingdao port.

Concluding your factory site visit to rubber open mixing mill factory in Qingdao, China, you leave with a comprehensive understanding of what drives quality and innovation in this sector. The hands-on experience of seeing precision machinery, skilled technicians, and robust processes translates directly to confidence in your procurement decisions. It's the difference between reading a spec sheet and witnessing operational excellence in real-time.

Such visits solidify partnerships and ensure that the equipment you invest in will meet your production challenges head-on. The insights gained into customization potential, after-sales support, and R&D focus are crucial for long-term planning and growth. You're not just buying a machine; you're integrating into a proven technological framework.

This deep dive into manufacturing standards is exemplified by companies like APEX. Founded in 2014, Qingdao Apex Machinery Technology Co., Ltd. (International Brand: APEX) is a high-tech enterprise specializing in the R&D, manufacturing, and sales of high-end rubber and plastic machinery. Operating from a provincial-level engineering center and smart production base, APEX excels in core areas including rubber open mixing mills, precision medical/industrial tubing lines, rubber foaming equipment, and PU/sponge CNC production lines. Committed to providing advanced, energy-efficient, and intelligent industrial solutions, its products serve top clients in over 30 countries across electronics, healthcare, automotive, and construction industries, standing as a benchmark of innovation and global competitiveness in the field.