Plastic Broom Filament Extrusion Line

Plastic broom filament drawing machine melts plastic, extrudes and stretches it into uniform, h...

Read More

PTT Synthetic Hair Fiber Production Line

PTT material dried, melted, extruded into filaments, stretched, cooled, wound into high-elastic...

Read More

Synthetic Fiber Extrusion Drawing Machine

PP/PE/PA raw materials melt into filaments, stretched, cooled, and wound for fluffy, strong syn...

Read More

Hair Wig Combing Shaping Machine / Fluffing Setting Machine

Wig fibers are combed, straightened, and fluffed via heat or vibration. PLC controls temp/tensi...

Read More

Plastic Makeup Brush Filament Extrusion Production Line

Plastic makeup brush filament drawing machine: high-precision micro-hole extrusion → cooling sh...

Read More

Plastic Synthetic Eyelash Filament Extrusion Line

APEX plastic eyelash drawing machine: micro-hole spinning → tension control → dynamic curling. ...

Read More

Synthetic Hair Fiber Extrusion Production Line

APEX synthetic hair fiber extrusion line produces high-quality, uniform-diameter (≤±0.01mm), sm...

Read More

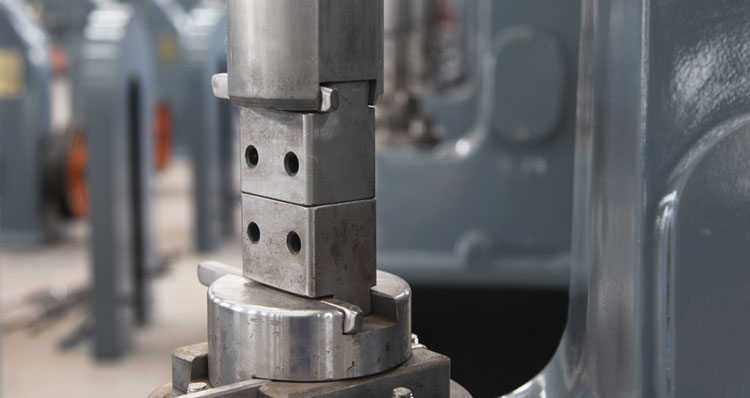

Plastic Toothbrush Filament Extrusion Production Line

A specialized, precise production line for extruding polymer filaments (e.g., nylon PA612, PA61...

Read More

Plastic Brush Filament Extrusion Line

Plastic brush filament extrusion line (universal) is designed for producing various general pla...

Read MoreOur Advantages

Compatible with Various Plastic Raw Materials

Supports various thermoplastics such as PA (Nylon), PET (Polyester), PP, PE, PVC, etc., meeting different requirements for hardness, toughness, and heat resistance.

Precise Filament Diameter Control

Capable of producing from ultra-fine filaments (0.01mm level) to thick filaments (several millimeters), meeting different applications (such as makeup brushes, cleaning brushes, industrial filaments, etc.).

Flexible Filament Shape Adjustment

Supports round filaments, flat filaments, profiled filaments, W-shaped filaments, spiral filaments, etc., adapting to various brush types and functional requirements.

Free Combination of Colors and Additives

Supports color masterbatch co-extrusion to produce plastic filaments in various colors; functional additives such as antibacterial, anti-UV, and flame retardant can also be incorporated.

Industry Focus, Rich Experience

With 10+ years in plastic filament manufacturing equipment, we focus on brush/cleaning/industrial filaments, serve 2000+ global clients, excel at customization & PA/PET/PP/PE proce…

Independent R&D, Leading Technology

Our professional R&D team (e.g., Qikechuangda Institute) covers mechanics, polymers & automation; with CAD/CAE/simulation, patents, customized molds/shapes/processes, we ensure top…

Standardized Production, Quality Assurance

Our modern base with CNC/sheet-metal equipment follows ISO9001 full-process control; top-brand key components and modular production ensure stable, durable equipment with consisten…

Customized Services, Full Support

We offer one-stop turnkey services (consultation to after-sales), personalized filament customization, value-added mold/process/raw material support, and trial sampling for stable …

Customer Reviews

Daniel

“APEX wig equipment is excellent! Carding machine reduces hair breakage to 1.5%, saves 7kg/day. CNC c...”

FROM: South African Custom…

Mohammed

“APEX car interior foaming machine is the right choice! Density deviation ±2kg/m³, rebound rate 58%, ...”

FROM: South African Custom…

Ivan

“As a small factory, we have a limited budget. Aipake foaming line (basic model) is 40% cheaper than ...”

FROM: Russian-Chinese Purc…