PRODUCT

Household Plastic Filament Extruder

This section focuses on extrusion production equipment and technical solutions for plastic filaments (such as nylon filaments, polyester filaments, PP/PE plastic filaments, etc.) used in the personal care and household fields. It covers the complete extrusion process from raw materials to finishe

Plastic Broom Filament Extrusion Line

Plastic broom filament drawing machine melts plastic, extrudes and stretches it into uniform, h...

Read More

PTT Synthetic Hair Fiber Production Line

PTT material dried, melted, extruded into filaments, stretched, cooled, wound into high-elastic...

Read More

Synthetic Fiber Extrusion Drawing Machine

PP/PE/PA raw materials melt into filaments, stretched, cooled, and wound for fluffy, strong syn...

Read More

Hair Wig Combing Shaping Machine / Fluffing Setting Machine

Wig fibers are combed, straightened, and fluffed via heat or vibration. PLC controls temp/tensi...

Read More

Plastic Makeup Brush Filament Extrusion Production Line

Plastic makeup brush filament drawing machine: high-precision micro-hole extrusion → cooling sh...

Read More

Plastic Synthetic Eyelash Filament Extrusion Line

APEX plastic eyelash drawing machine: micro-hole spinning → tension control → dynamic curling. ...

Read MoreIndustrial and Agricultural Plastic Wire Extrusion Machine

Aipake Machinery designs customized extrusion production lines for plastic wire needs in the industrial/rope net, construction/agricultural sectors. Integrating high-precision equipment, intelligent control, and energy-saving technology, it addresses industry pain points such as 'insufficient

Net Bag / Fruit Net / PE Foam Net Extrusion Production Line

Net/Fruit/PE foam net extrusion line: efficient extrusion, foaming, cooling, winding. Mesh 0.5-...

Read More

Artificial Turf Production Line

Produces synthetic grass via automated weaving, PLC-controlled density, and uniform backing for...

Read More

Plastic Rope Filament Extrusion Line

Plastic rope filament drawing machine, PP/PE pellet melt extrusion→stretching→cooling→winding, ...

Read More

Plastic Paint Brush Filament Extrusion Line

Plastic paint brush filament line: precision extrusion, cooling, winding. Diameter ±0.01mm, mic...

Read MoreMedical Hose Production Line

Focusing on the medical hose field, in-depth analysis of the technology, equipment and production solutions for medical hose production lines. Covering the entire production process of infusion tubes, catheters, blood bag tubes, medical-grade hoses, etc., made of materials such as silicone, PVC,

Precision Medical Tube PVC/Polyurethane Dual-Color Extrusion Line

Dual hopper feeding, PVC & polyurethane co-extruded into dual-color tube. Laser gauging control...

Read MoreHose/Water Pipe Production Line

Focusing on the hose and water pipe production field, in-depth analysis of technology and equipment for PVC, PE, PPR, silicone, and composite material production lines, covering multiple scenarios such as industrial pressure pipes, agricultural irrigation pipes, building water supply pipes, fire

PVC Water and Air Fiber Hose Extrusion Line

PVC resin melts and extrudes, reinforced with composite woven fiber, shaped in cooling tank, co...

Read More

PPR / PP Cold and Hot Water Pipe Plastic Extrusion Production Line

Two-stage extrusion of PPR/PP material, vacuum sizing cooling, constant speed traction, PLC tem...

Read MoreRubber Foam Insulation Material Production Line

Focusing on the rubber foam and insulation material sector, integrating core processes such as rubber vulcanization foaming, polyurethane/phenolic/rubber-plastic insulation material molding, etc., covering fields like building insulation, automotive interiors, industrial thermal insulation, and h

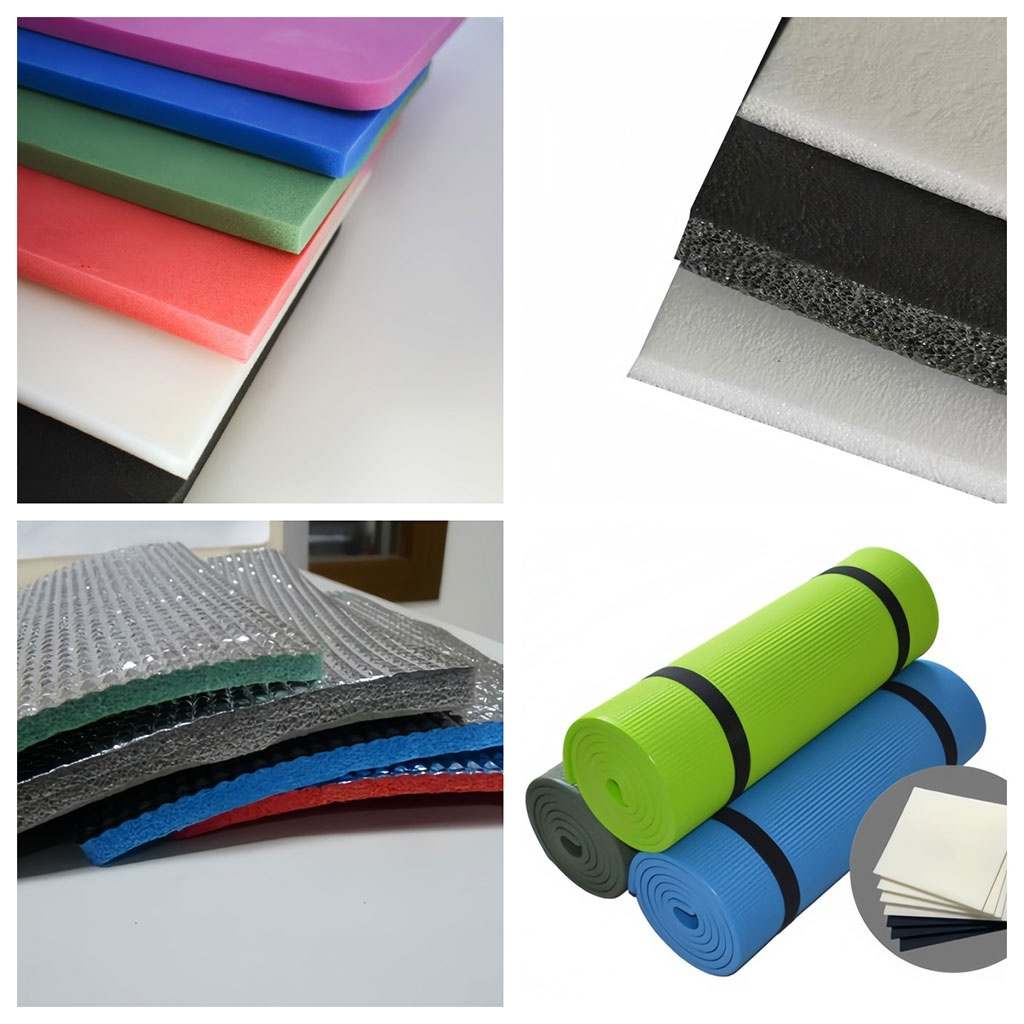

XPE/IXPE Foam Material Production Line

XPE/IXPE foam line: mixing, extrusion, cross-linking, molding, cooling, PLC control for uniform...

Read More

Precast Rubber Track Equipment

PU/EPDM precast rubber track production line: mixing, extrusion, vulcanization, laser thickness...

Read More

Rubber Foot Mat/Floor Mat/Yoga Mat/Mouse Pad Production Line

EPDM/TPE/PVC rubber mat line: mixing, extrusion, embossing, continuous vulcanization, laser tri...

Read More

NBR/PVC Sheathing & Profile Production Line

NBR/PVC twin-screw co-extrusion line for oil-resistant, flame-retardant, elastic sheaths. Used ...

Read More

Rubber Foam Tube/Sheet Production Line

Rubber mixed with foaming agent extruded, cooled, cut, coiled. Uniform closed cells, good elast...

Read MoreRubber Machinery Equipment

Rubber machinery equipment is the core equipment for rubber product production, covering the entire process from raw material processing to finished product molding. It is widely used in tires, seals, hoses, belts, rubber products, and other fields. Main equipment includes internal mixers, open m

Film Cooling Machine

Film cooling machine manufacturer: roller/air-cooled, ±1°C temp control, PLC speed, online thic...

Read More

T-Type Twin Screw Extrusion Sheeting Machine

APEX: T-Type twin screw extrusion sheeting machine for PVC/engineering plastics. Uniform mixing...

Read More

Four Roll Calender

Four-roll calender precisely extrudes PVC/PE/TPE/TPU via L/S-type rollers with temp control & s...

Read More

Three Roll Calender

APEX three roll calender for PVC/PE/PP/TPE sheets/films. I-type/inverted L-type, PLC temp contr...

Read More

Pin Type Extruder

APEX pin extruder enhances shear mixing via pins, ensures uniform dispersion, PLC controls temp...

Read More

Vented Extruder

APEX vented extruder for PA/PET: degassing screw + vacuum drying, multi-zone temp control, PLC ...

Read MoreRubber Profile Production Line

APEC (Qingdao) Mechanical Technology's rubber profile production line factory specializes in the R&D and manufacturing of production equipment for rubber sealing strips, hoses, profiles, and other products, covering building, automotive, and industrial sealing fields. The factory is equip

Rubber Sealing Strip / Profile Production Line

Produces full-process equipment for mixing, extrusion, vulcanization. For EPDM/TPE/PVC. Twin-sc...

Read More

Wide Film Extrusion Calendering Production Line

Wide film extrusion line: mixing, extrusion, 5-roll calendering, cooling & winding for PVC/PE/E...

Read More

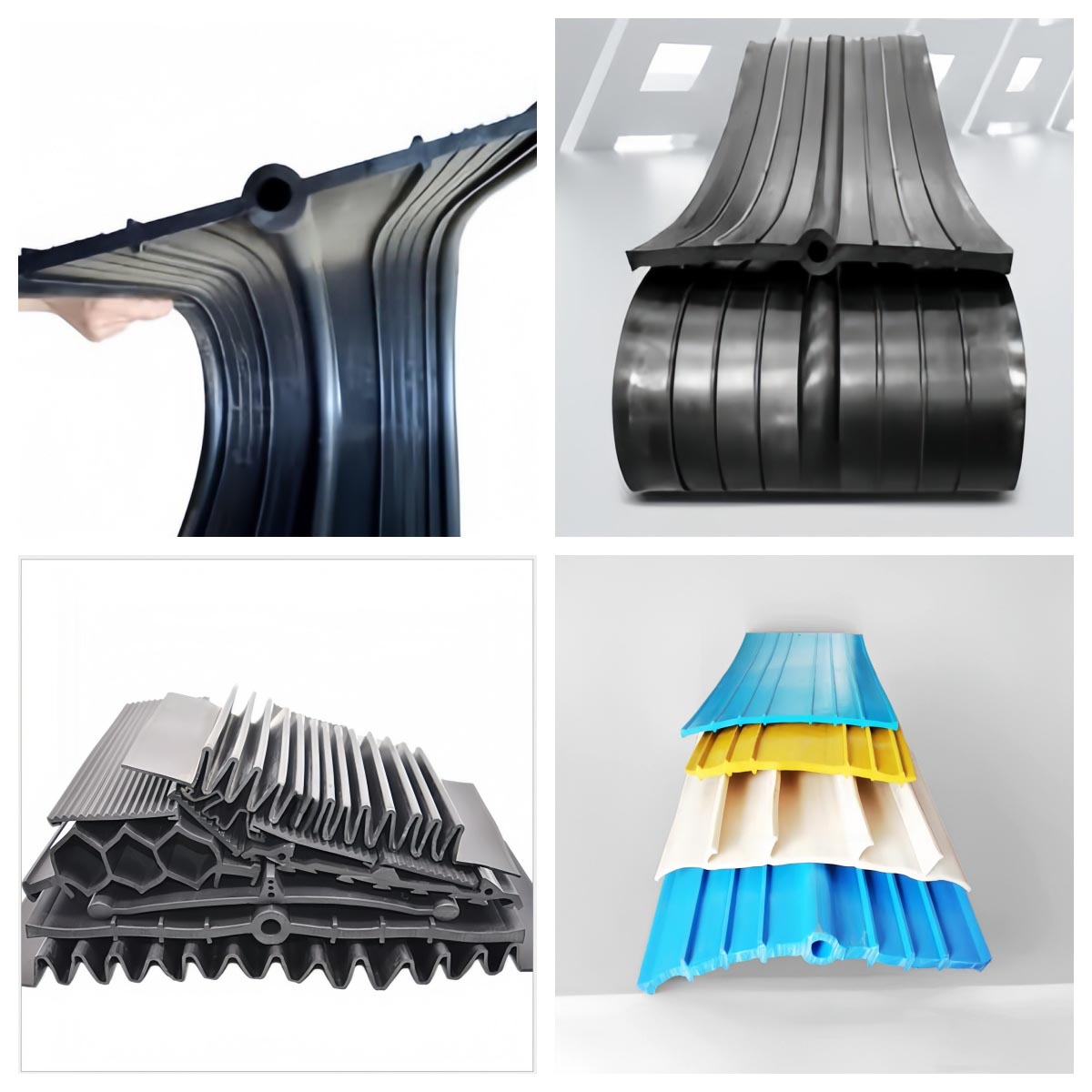

Rubber Waterstop Production Line

APEX produces full-process equipment for rubber waterstop, including mixing, extrusion, vulcani...

Read More

TPR / TPE / TPU Rubber Band Production Line

TPR/TPE/TPU rubber band line: pre-mix elastomer, single screw extrude, stretch orient, cool set...

Read More

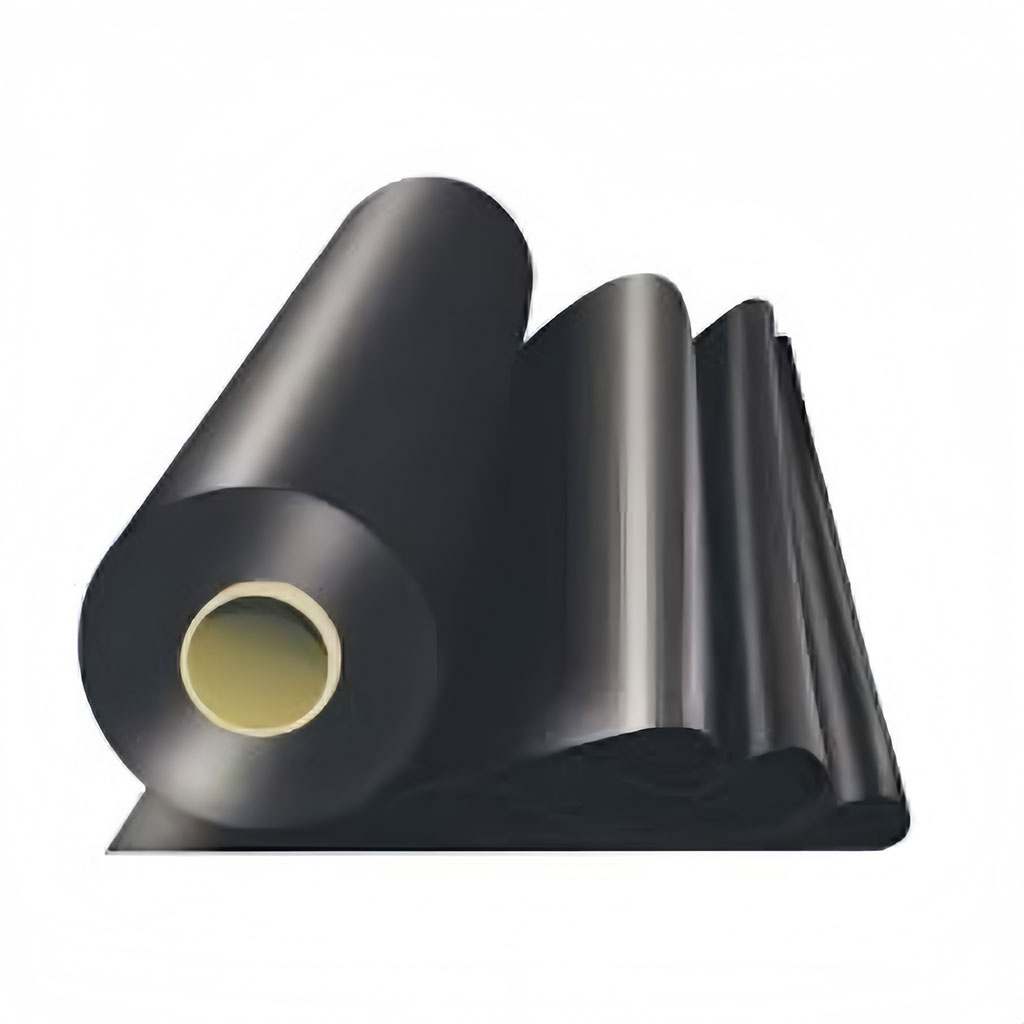

EPDM Waterproofing Membrane Production Line

APEX EPDM waterproofing membrane line: mixing, extruding, continuous vulcanizing, laser thickne...

Read More

Rubber Seal Production Line

APEX provides full-process equipment for mixing, extrusion, and vulcanization, compatible with ...

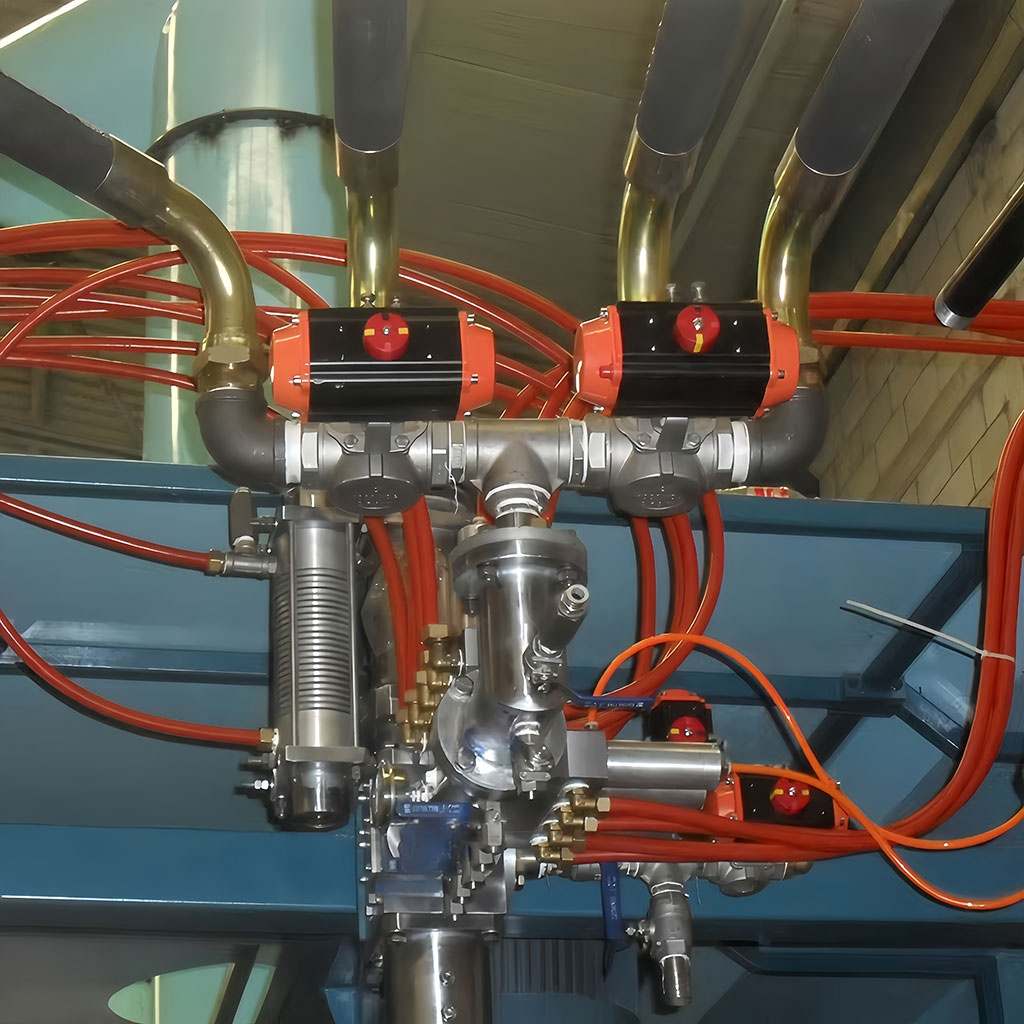

Read MorePolyurethane Foaming Machine

The polyurethane foaming machine is the core equipment for producing polyurethane foam. It precisely mixes multi-component raw materials (isocyanate, polyether polyol, etc.) to form uniform foam through high-pressure impact or spray reaction. It is widely used in building insulation, automotive i

Polyurethane Foaming Machine

High/low-pressure foaming machines, precision mixing head (±1%), CNC temp/pressure control, uni...

Read MoreCNC Sponge Continuous Production Line

The CNC Sponge Continuous Production Line is an intelligent equipment integrating CNC technology and continuous foaming process, specializing in the production of mattress core materials, furniture sponges, automotive interiors, and packaging cushioning materials. The equipment is equipped with a

CNC Sponge Continuous Production Line

PU/PVA materials mixed via CNC pumps, ±2°C foaming, continuous forming, ±1mm cutting, PLC densi...

Read MoreMechanical Parts Series

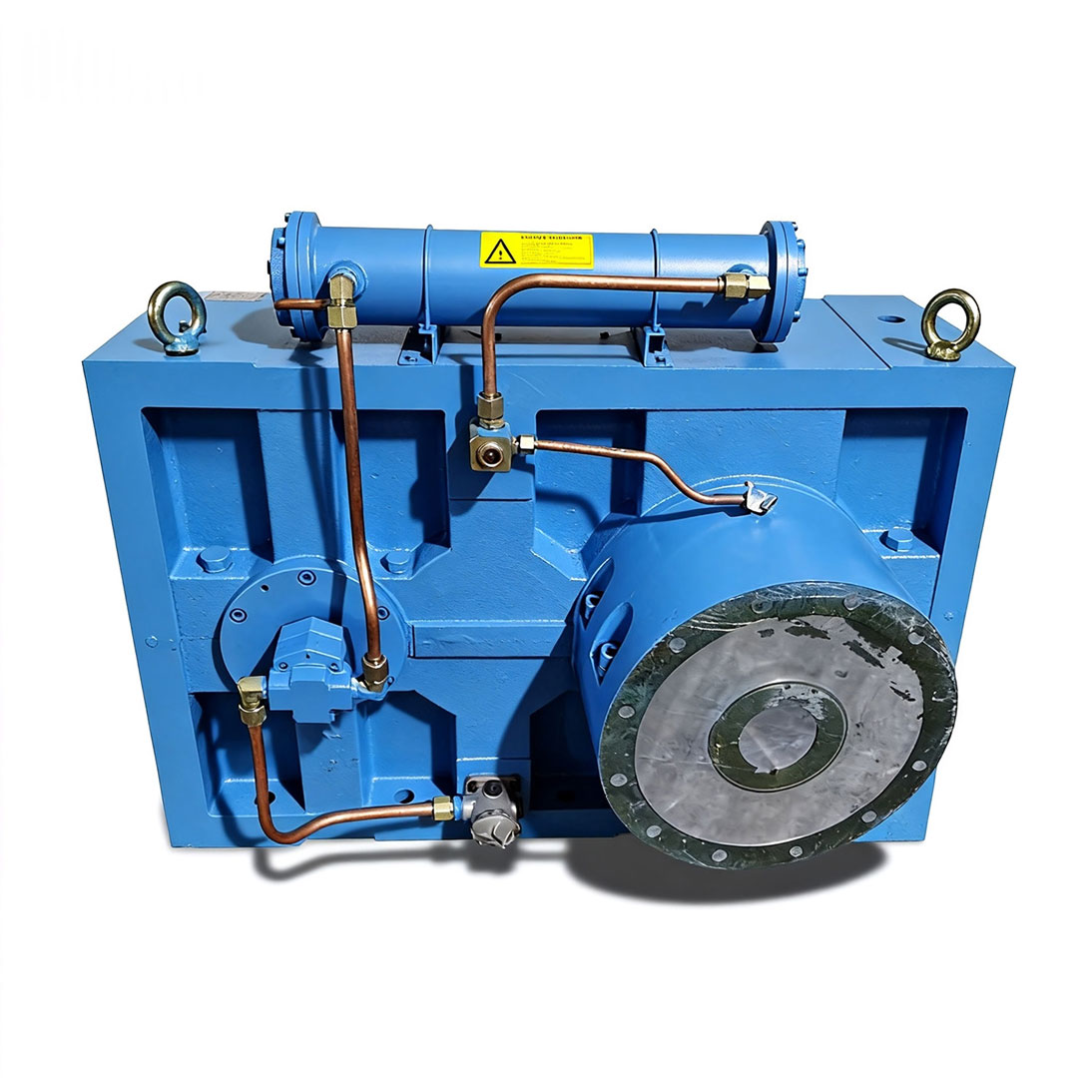

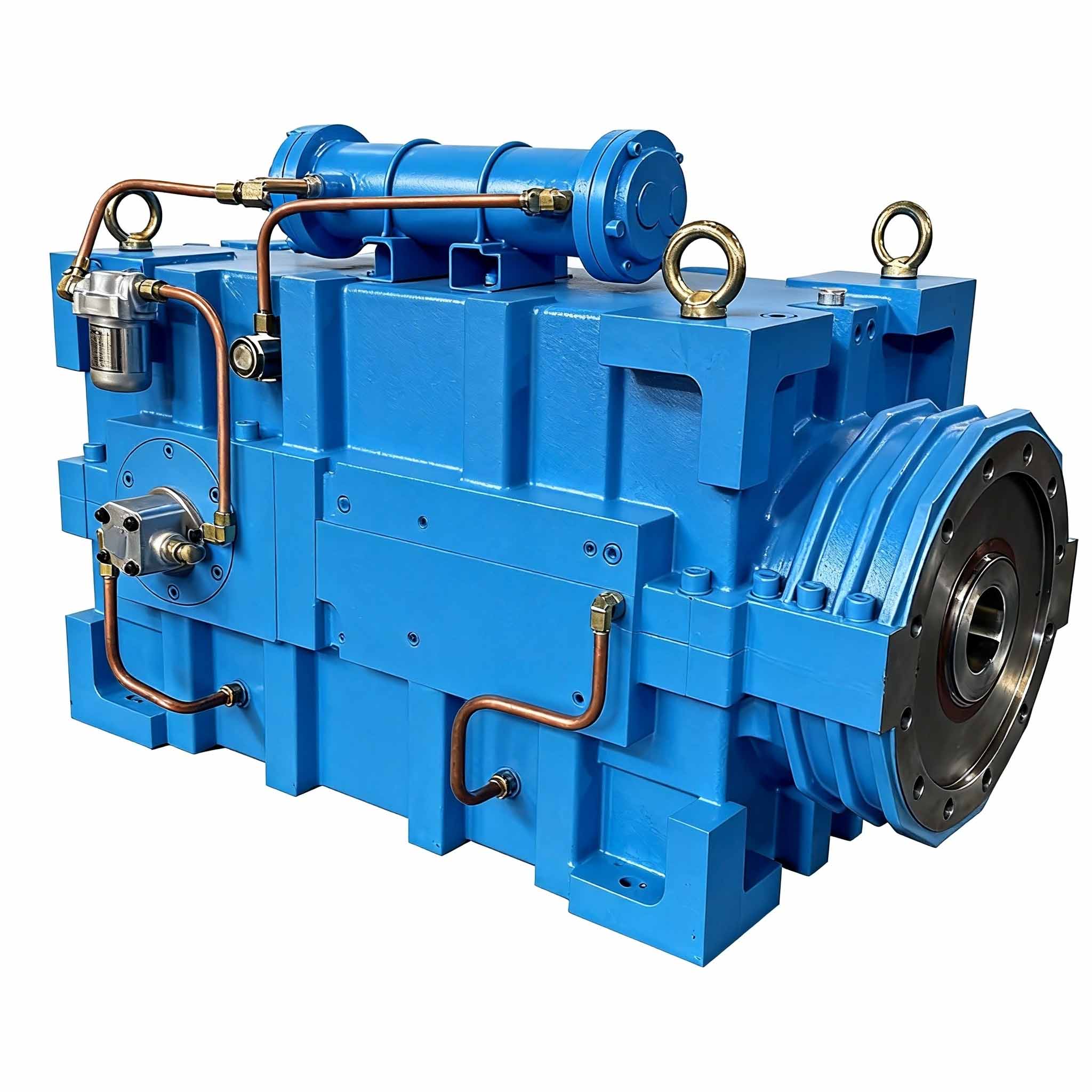

The transmission of a gear reducer is based on the gear ratio (or diameter ratio) to achieve the conversion of speed and torque. Taking the most typical gear reducer as an example:

The pinion gear on the input shaft (driving gear) meshes with the large gear on the output shaft (driven gea

ZLYJ Series Vertical Hardened Gear Reducer

Reducer reduces speed, increases torque via gears, converts high-speed low-torque input to low-...

Read More

ZLYJ Series Hardened Gearbox

APEX: China reducer & gearbox manufacturer. Plastic machinery parts, gearboxes, reducer accesso...

Read More

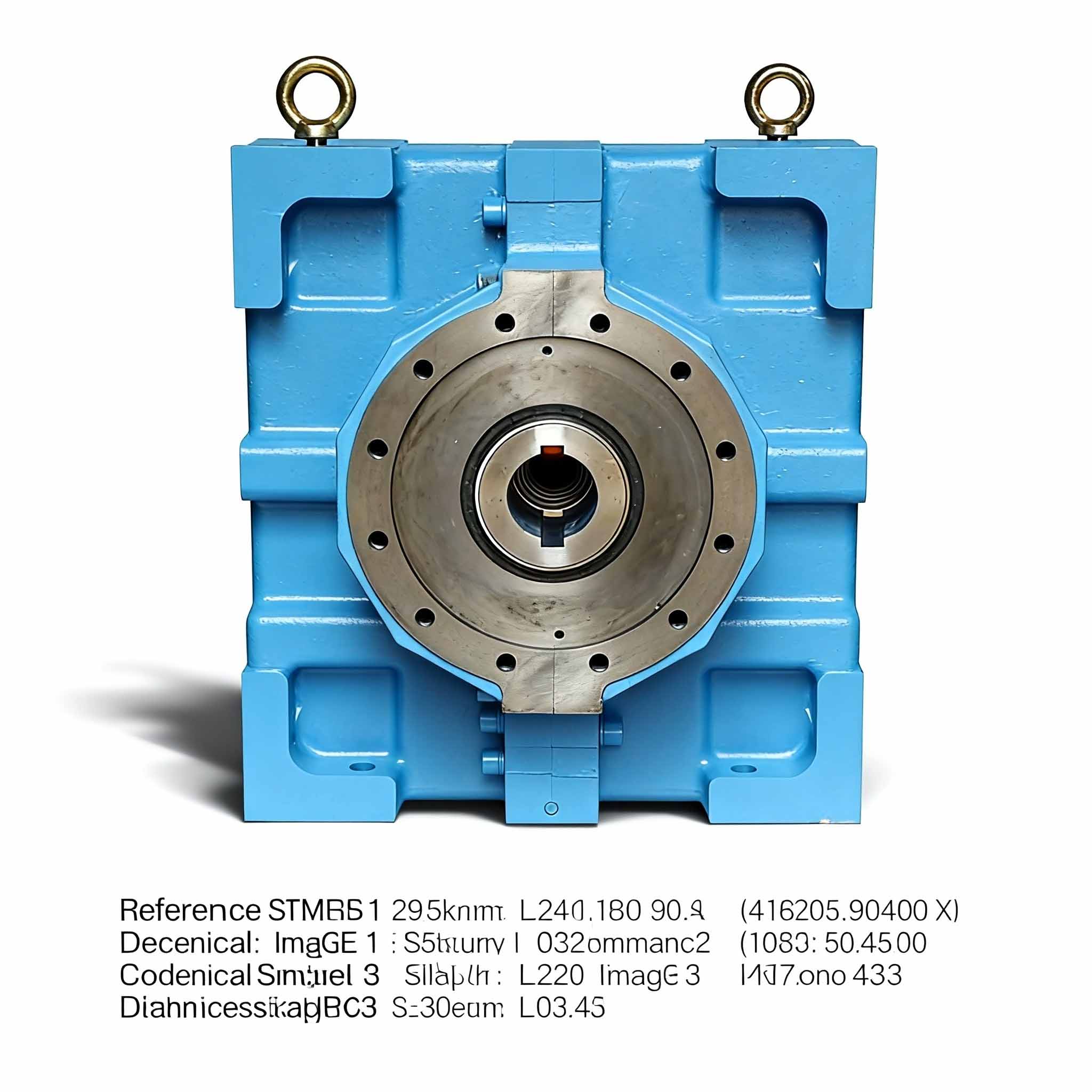

SG Series Vertical Hardened Gear Reducer

Reducer manufacturer, gearbox manufacturer, plastic parts, gearbox, reducer parts, plastic mach...

Read More

SG Series Hardened Gearbox

China gearbox maker, plastic parts, gearboxes, reducer components, plastic machinery parts, ext...

Read More

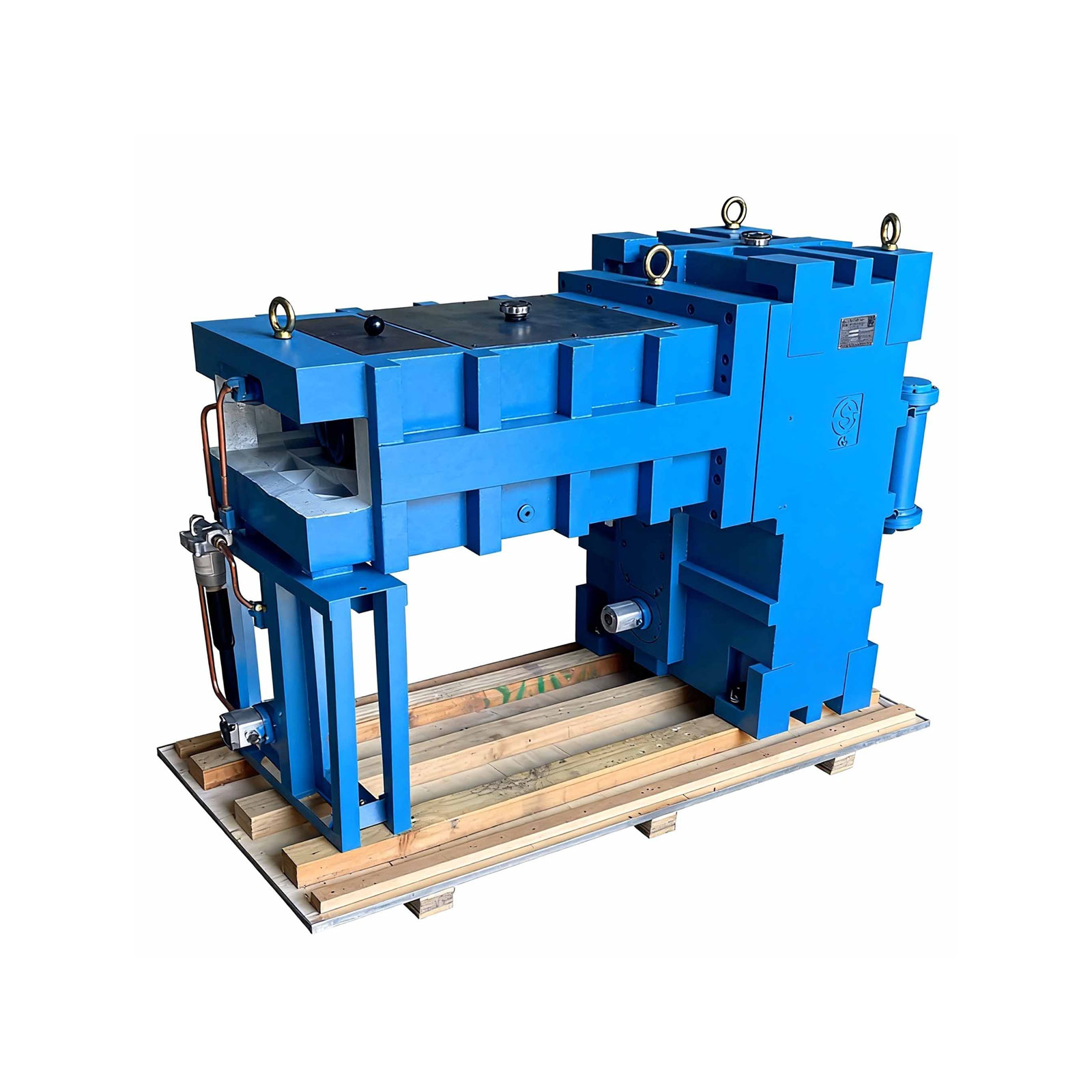

SGT Series Vertical Integral Cone Double Reducer

SGT vertical integral cone double reducer features compact vertical design with two-stage harde...

Read More

SZL Series Vertical Integrated Conical Double Gearbox

SZL vertical integrated conical double gearbox features cast steel housing, double-stage hard g...

Read MoreSimulation Plant Manufacturing Machine

Aipake Mechanical Technology - Introduction to the Simulation Plant Manufacturing Machine Section

【Aipake Mechanical Technology – Professional Intelligent Manufacturer of Simulation Plant Manufacturing Equipment · Full Chain Solution Provider】

This section focuses on the core advantag

Simulated Plant Skeleton Molding Machine

Professional skeleton molding for artificial plants. Covers all types. Smart CNC & modular mold...

Read More

Simulation Plants

APEX simulation plants replicate nature with 3D tech & eco-materials, offering lifelike flowers...

Read More

Simulation Flower Making Machine

Specializes in simulation flower making equipment, supplying fully/semi-automatic production li...

Read More

Simulated Plant Maker - Pine Needle Tree

Direct supply of simulated plant manufacturing equipment, with fully/semi-automatic production ...

Read More