INTRODUCTORY

“In 2014, as the blueprint for 'Made in China 2025' was unfolding, Qingdao, this maritime industrial hub, was ushering in a golden opportunity for high-end equipment manufacturing. Driven by the original aspiration of 'reshaping industrial value through technological innovation,' Apex (Qingdao) Mechanical Technology Co., Ltd. (hereinafter referred to as 'Apex') was established on the shores of the Yellow Sea. As a high-tech enterprise focusing on the R&D and manufacturing of high-end mechanical equipment and intelligent industrial solutions, we have always taken 'solving industry pain points and promoting industrial intelligent upgrading' as our core mission. After nearly a decade of deep cultivation, we have grown into a benchmark enterprise in the domestic mechanical technology field with both innovation and competitiveness. Our business covers over 30 countries and regions worldwide, serving more than a thousand leading customers in the industrial sector. From the initial technology tackle key problems laboratory to the current industrial platform with intelligent production bases and provincial engineering technology centers, every step of Apex's growth is marked by the genes of 'focus, breakthrough, and integration.' We believe that the future of industry is not only about equipment iteration but also the deep integration of technology and needs—and this belief continues to drive us forward.”

张

Kai

Company History

Zero-Carbon Equipment R&D

Initiated zero-carbon equipment R&D to accelerate global market expansion.

Dual-Carbon Strategy

Deepening the dual-carbon strategy, energy-saving products help customers reduce costs and emissions.

High-Tech Enterprise

Recognized as a National High-Tech Enterprise, transitioning into an intelligent solution service provider.

Product Launch

The first precision gearbox rolled off the production line and obtained TÜV certification for export to Southeast Asia.

Founded Aipaike

Anchored in R&D of core components for rubber and plastic machinery

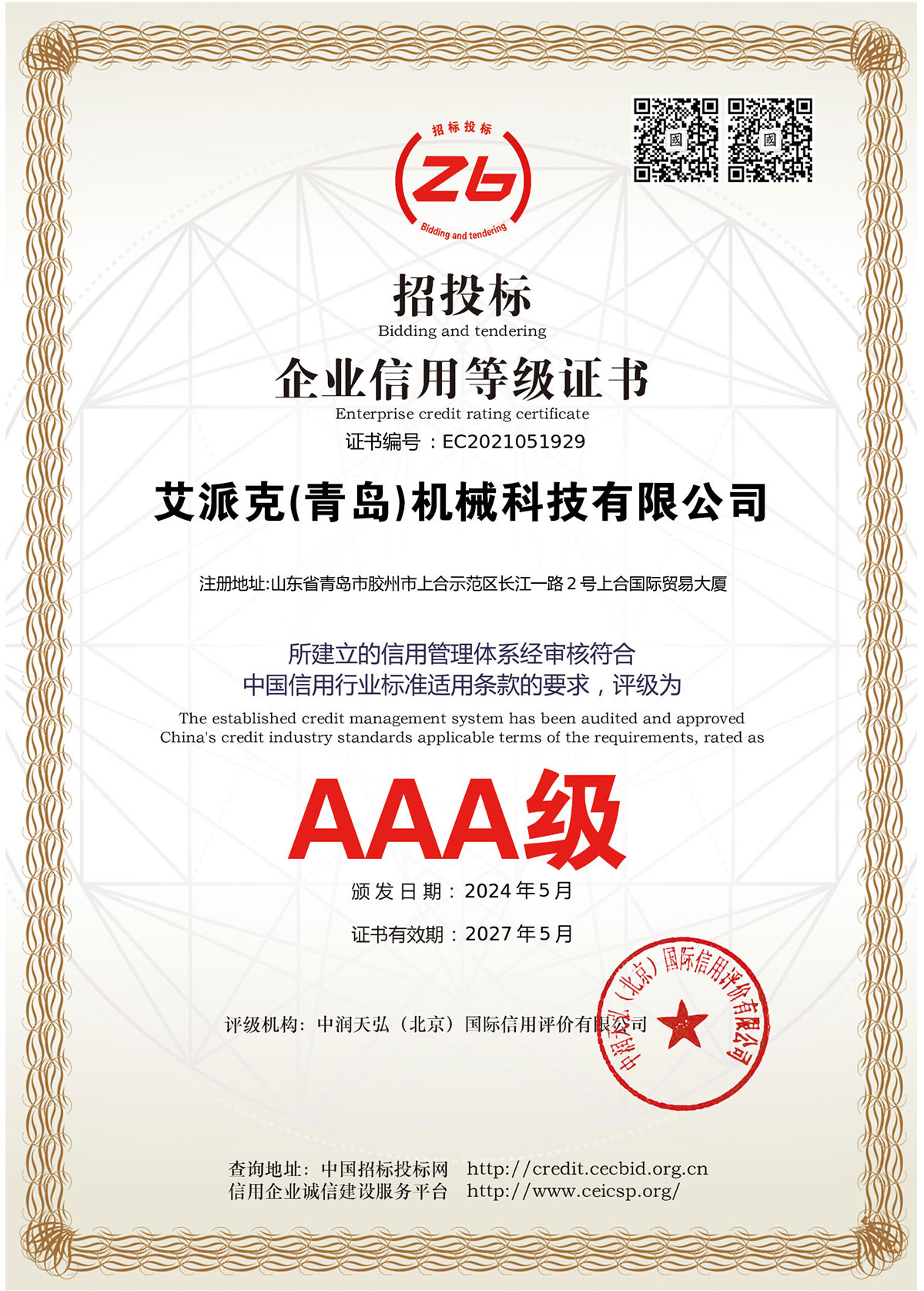

企业资质

“APEX wig equipment is excellent! Carding machine reduces hair breakage to 1.5%, saves 7kg/day. CNC cutter precision ±0.5mm, yield 99.2%. Solves breakage, frizz, length issues. Highly recommended for wig makers.”

Daniel

South African Customer

“APEX car interior foaming machine is the right choice! Density deviation ±2kg/m³, rebound rate 58%, no bubbles/eccentricity, pass rate 100%. Multi-density zoning, 30% efficiency boost. Bio-based PU, no harmful gases, meets EU REACH standards.”

Mohammed

South African Customer

“As a small factory, we have a limited budget. Aipake foaming line (basic model) is 40% cheaper than imported equipment but performs well. Density control ±3kg/m³, no surface defects, meets export standards. Easy to operate, workers trained in 2 days.”

Ivan

Russian-Chinese Purchaser